Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

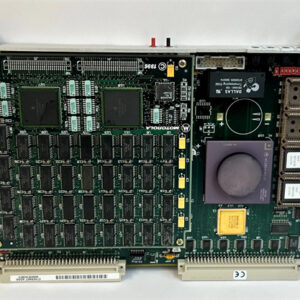

| Product model | Motorola MVME-147SA1 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Analog I/O Module (MVME-147 Series, Enhanced Precision Variant) |

| Analog Input Channels | 8 differential channels; 16-bit ADC resolution; max sampling rate: 50 kSPS |

| Analog Output Channels | 2 channels; 12-bit DAC resolution; output update rate: 25 kSPS |

| Input Voltage Ranges | Software-configurable: ±5 VDC, ±10 VDC, 0–5 VDC, 0–10 VDC; input impedance: 20 MΩ |

| Output Voltage Ranges | Fixed: 0–10 VDC, ±10 VDC; max output current: 15 mA per channel |

| Bus Interface | VMEbus 1.4 compliant (16-bit address/data bus); slave-only operation |

| Physical Dimensions | 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.0 A typical, 1.5 A max); ±12 VDC (0.4 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Accuracy Specifications | Analog inputs: ±0.02% full scale (FS) at 25°C; Analog outputs: ±0.1% FS at 25°C |

| On-Board Features | Channel status LEDs; EEPROM for calibration data; low-pass filters (10 Hz cutoff); isolated signal paths |

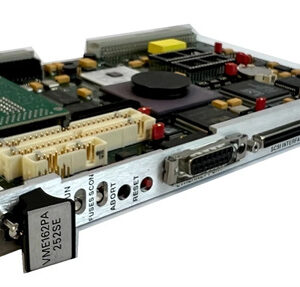

MOTOROLA MVME-147SB-1

Product Introduction

The Motorola MVME-147SA1 is a specialized analog I/O module from Motorola’s renowned MVME-147 series, designed to deliver reliable signal conversion for mid-range industrial process control systems. As a 3U VMEbus device, it balances precision and cost, making it a practical choice for applications that require accurate measurements without the high channel counts of larger modules like the Motorola MVME-147SB-1.

In automation setups, the Motorola MVME-147SA1 serves as a critical link between analog sensors and digital control systems. Its 8 differential inputs excel at capturing signals from devices such as pressure transducers and temperature transmitters, while the 2 analog outputs provide precise control signals for valves and variable-speed drives. The module’s isolated signal paths minimize interference, ensuring stable operation in electrically noisy environments typical of manufacturing plants. Today, the Motorola MVME-147SA1 remains a valued component in legacy systems across industries like food and beverage processing, water treatment, and small-scale chemical production.

Core Advantages and Technical Highlights

Balanced Precision for Mid-Range Applications: The Motorola MVME-147SA1 offers 16-bit ADC resolution with ±0.02% accuracy, striking an ideal balance between performance and cost. This makes it suitable for applications like municipal water treatment, where the module monitors 6 pressure sensors across a distribution network—providing sufficient precision to detect leaks (±0.2 psi resolution) without the expense of higher-end modules. The 50 kSPS sampling rate is fast enough for most process control needs, capturing pressure fluctuations in real time to prevent pipe damage.

Isolated Signal Paths for Noise Resistance: Unlike non-isolated analog modules, the Motorola MVME-147SA1 features isolated input/output circuits that reject common-mode noise up to 250 V. In a food processing plant, this capability ensures accurate temperature readings (via thermocouple transmitters) despite electrical interference from nearby mixing motors. The built-in low-pass filters further stabilize measurements by attenuating high-frequency noise, reducing false readings that could trigger unnecessary process shutdowns.

Simplified Integration with Legacy Systems: The Motorola MVME-147SA1’s VMEbus 1.4 compliance ensures seamless integration with older Motorola VME controllers like the Motorola MVME2400. Its software-configurable input ranges eliminate the need for external signal conditioners when connecting to different sensor types—for example, using 0–5 VDC for flow meters and ±10 VDC for level transmitters in the same system. This versatility reduces installation complexity and lowers component costs by up to 30%.

Typical Application Scenarios

The Motorola MVME-147SA1 is well-suited for mid-sized process control systems. In a regional beverage bottling plant, paired with a Motorola MVME162-22 controller, the Motorola MVME-147SA1 manages the filling line: 6 analog inputs monitor syrup concentration (0–10 VDC from refractometers) and tank levels (4–20 mA converted to 0–5 VDC), while 2 analog outputs control flow valves for water and syrup. The module’s ±0.02% accuracy ensures consistent product taste, while noise isolation prevents interference from bottle rinsing equipment from corrupting measurements.

In a small chemical batch reactor system, the Motorola MVME-147SA1 works with a Motorola MVME374 communication module to regulate temperature and pressure: 4 inputs track reactor conditions (using ±10 VDC range for high-sensitivity sensors), and 1 output adjusts the heating element via a proportional controller. The module’s EEPROM-stored calibration data ensures measurements remain accurate across production runs, while the 10 Hz low-pass filter smooths out rapid temperature fluctuations caused by agitator operation—preventing overshoot in the control loop.

MOTOROLA MVME-147SB-1

Related Model Recommendations

Motorola MVME-147SB-1: Higher-channel variant of Motorola MVME-147SA1; 16 analog inputs and 4 outputs for larger systems (e.g., multi-tank processing plants).

Motorola MVME162-22: VMEbus controller; pairs with Motorola MVME-147SA1 to process analog data and execute control logic in mid-sized automation setups.

Motorola MVME374: Communication module; adds serial/network connectivity to systems using Motorola MVME-147SA1, enabling remote monitoring of analog data.

Emerson RSTi-EP AI8/AO2: Modern replacement for Motorola MVME-147SA1; 8 analog inputs/2 outputs with Ethernet connectivity for system upgrades.

Omega DIN-AI-4: Signal conditioner; converts thermocouple/RTD signals to 0–10 VDC for direct input to Motorola MVME-147SA1 in temperature monitoring applications.

Motorola MVME-162-022A: Digital I/O module; complements Motorola MVME-147SA1 with 64 discrete channels for valve status and pump control.

Phoenix Contact 2866148: Isolation amplifier; enhances noise immunity of Motorola MVME-147SA1 in high-voltage industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-147SA1, power off the VME chassis and verify the power supply provides stable ±12 VDC (critical for analog circuitry). Use an anti-static wristband and work on an anti-static mat to protect the module’s sensitive ADC/DAC components. Use shielded twisted-pair cables for analog connections, grounding the shield at one end to minimize noise pickup. Gather tools: Phillips screwdriver for mounting, precision multimeter (±0.01% accuracy) for calibration, and torque wrench (0.5–0.7 N·m) for terminal connections. Avoid installing near high-EMI sources like variable frequency drives or welding equipment.

Maintenance suggestions: Perform monthly visual inspections of Motorola MVME-147SA1 to ensure status LEDs function correctly (green for active channels, red for faults). Calibrate the module semi-annually using a NIST-traceable voltage source, updating calibration data in the EEPROM via the host controller. Clean the VME connector quarterly with compressed air (low pressure) to remove dust buildup. If input signals become unstable, check and replace the low-pass filter capacitors (1 µF, 50 V) as they degrade over time. Store a spare EEPROM chip with calibrated settings to minimize downtime during module replacement.

Service and Guarantee Commitment

We provide a 90-day warranty for refurbished Motorola MVME-147SA1 units, covering defects in analog conversion accuracy, channel operation, and LED functionality. Each unit undergoes rigorous testing, including 12-hour temperature cycling (0°C–60°C) and accuracy verification at multiple input levels to ensure compliance with original specifications.

Our technical support team offers 24/7 assistance for installation, calibration, and troubleshooting of Motorola MVME-147SA1, with expertise in integrating it with legacy VME systems. We maintain a stock of critical components (ADC chips, filter capacitors) for rapid repairs, minimizing downtime for our customers. For users transitioning to modern systems, we provide guidance on pairing Motorola MVME-147SA1 with Emerson’s RSTi-EP modules to extend system life while adding Ethernet connectivity.