Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

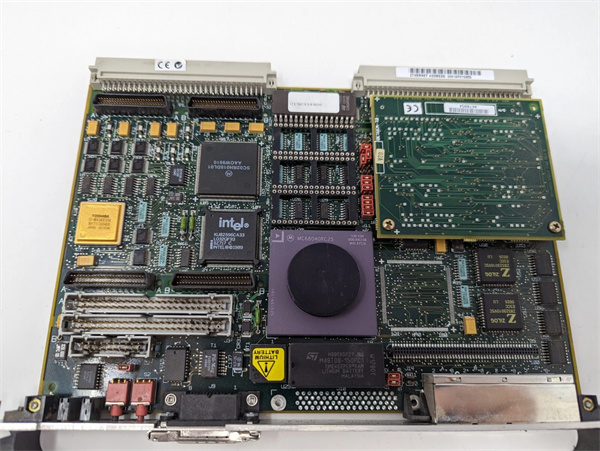

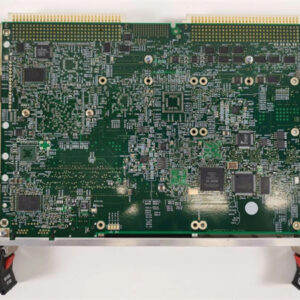

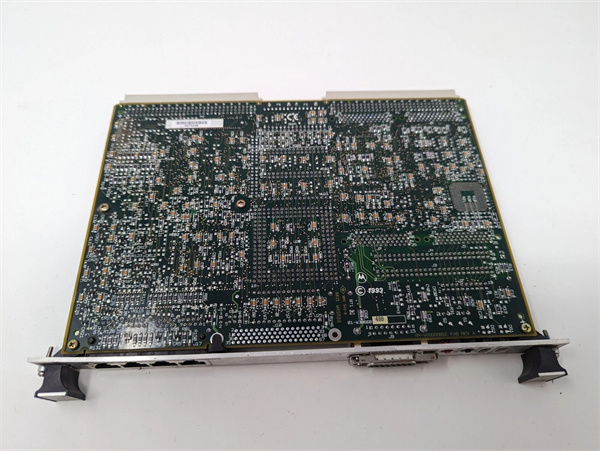

| Product model | Motorola MVME 162-22 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Embedded Controller (MVME 162 Series Mid-Range Variant) |

| Processor Options | 25/32 MHz MC68040 (32-bit, 8KB cache, MMU, FPU); 25 MHz MC68LC040 (no FPU) |

| Memory Configuration | 4–32 MB ECC/parity DRAM (expandable to 64 MB); 128 KB battery-backed SRAM; 1 MB flash; 8K×8 NVRAM + RTC |

| Communication Interfaces | 4x EIA-232-D serial ports (DTE); optional 10/100 Mbps Ethernet; optional SCSI |

| Expansion Ports | 2x Industry Pack (IP) slots (supports I/O, communication, analog modules) |

| Timers | 6x 32-bit timers (4x VMEbus-independent); 1x hardware watchdog timer |

| VMEbus Compliance | VMEbus 1.4 (32-bit address/64-bit data); master/slave mode; 4-level arbitrator |

| Physical Dimensions | Dual-height VME form factor (160 mm × 100 mm × 32 mm; L×W×H) |

| Power Requirements | +5 VDC (2.5 A typical, 3.0 A max); +12 VDC (0.5 A typical); -12 VDC (0.3 A typical) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2, UL 508 |

MOTOROLA MVME 162-22

Product Introduction

The Motorola MVME 162-22 is a legacy mid-range embedded controller from Motorola’s iconic MVME 162 series, engineered to deliver versatile processing and I/O integration for VMEbus-based industrial automation systems. As a dual-height VME device, it bridges the gap between entry-level controllers (e.g., Motorola MVME 162-01) and high-end models, offering configurable processing power and expandability to meet mid-scale application needs.

In automation architectures, the Motorola MVME 162-22 acts as a “central processing hub”: its MC68040/LC040 processor handles real-time control logic, while expandable memory and Industry Pack slots support custom I/O (e.g., analog sensors, digital actuators) and communication (Ethernet/SCSI) for factory floors. For example, in a packaging line, the Motorola MVME 162-22 processes sensor data via IP modules, executes sorting algorithms, and transmits production logs via serial/Ethernet—all while ensuring 24/7 reliability. Today, it remains critical for maintaining legacy systems in automotive, food processing, and utilities, where replacing proven controllers would disrupt workflows.

Core Advantages and Technical Highlights

Flexible Processing for Mixed Workloads: The Motorola MVME 162-22’s dual-processor options (MC68040/LC040) let users match performance to application needs. The MC68040’s FPU excels in precision tasks like temperature control (e.g., plastic extrusion, ±0.1°C accuracy), while the MC68LC040 reduces costs for basic I/O control (e.g., conveyor timing). This flexibility avoids overpaying for unused FPU power—cutting hardware costs by 20% for non-calculation-heavy projects.

Expandable I/O via Industry Pack Slots: Unlike fixed-I/O controllers, the Motorola MVME 162-22’s 2 Industry Pack slots support hundreds of third-party modules (e.g., 16-channel analog I/O, CAN bus). In a water treatment plant, adding an IP analog module lets the Motorola MVME 162-22 monitor 8 pH sensors, while a digital IP module controls 16 valves—no full controller replacement needed. This expandability extends the module’s service life by 5–7 years.

Reliable Memory for Critical Data: The Motorola MVME 162-22’s ECC DRAM and battery-backed SRAM ensure data integrity in harsh environments. ECC corrects single-bit errors (common in dusty factories) to prevent control logic crashes, while SRAM retains configuration data during power outages. In a chemical batch process, this means no lost recipes or cycle data—avoiding $10k+ in wasted materials per outage.

Typical Application Scenarios

The Motorola MVME 162-22 excels in mid-scale industrial control. In an automotive component plant, paired with a Motorola MVME 162-022A I/O module, the Motorola MVME 162-22 controls a robotic assembly cell: its MC68040 processor calculates gripper positions (using FPU for precision), 4 serial ports connect to barcode scanners (tracking parts), and an Ethernet IP module sends production data to a factory SCADA system. The watchdog timer also triggers a safe shutdown if communication fails—preventing costly robot collisions.

In a municipal wastewater plant, the Motorola MVME 162-22 manages 4 pump stations: an analog IP module monitors flow/pressure sensors, a digital IP module controls pump relays, and battery-backed SRAM stores pump runtimes (critical for maintenance scheduling). Its -20°C storage range survives winter shutdowns, while ECC DRAM resists electrical noise from nearby pumps. For the plant, the Motorola MVME 162-22 avoids the $50k cost of upgrading to a modern PLC, as it still reliably handles daily operations.

MOTOROLA MVME 162-22

Related Model Recommendations

Motorola MVME 162-220: Entry-level sibling of Motorola MVME 162-22; 16 MB max DRAM (no ECC) for low-cost basic control (e.g., small conveyors).

Motorola MVME 162-223: High-end variant of Motorola MVME 162-22; 64 MB DRAM + integrated Ethernet for data-intensive tasks (e.g., real-time analytics).

Motorola MVME 162-022A: Digital I/O module; pairs with Motorola MVME 162-22 to add 64 discrete channels (e.g., valve/indicator control).

Emerson RSTi-EP CPE: Modern replacement for Motorola MVME 162-22; Ethernet-based, supports legacy IP modules via adapters for factory upgrades.

Motorola MVME 335A: Serial/parallel module; adds RS-485 to Motorola MVME 162-22 for long-distance sensor connectivity (e.g., pump stations 1km away).

Phoenix Contact IP-AI-16: Industry Pack analog module; expands Motorola MVME 162-22 to 16 analog inputs (e.g., temperature/pressure sensors).

Motorola FLN4234A: Ethernet gateway; bridges Motorola MVME 162-22 to cloud platforms (e.g., remote pump monitoring).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME 162-22, power off the VME chassis and verify compatibility with ±12 VDC (many modern chassis need adapters). Use an anti-static wristband to protect the processor/memory. Gather tools: Phillips screwdriver (chassis mounting), torque wrench (0.5–0.8 N·m for terminals), and a serial cable (for initial configuration). Avoid installing near variable-frequency drives (VFDs)—electrical noise can corrupt DRAM.

Maintenance suggestions: Monthly, inspect Motorola MVME 162-22’s LEDs (power/good = steady green; error = red). Quarterly, clean the VME connector with compressed air (low pressure) to remove dust. Every 2 years, replace the SRAM backup battery (3V lithium) to prevent data loss. If ECC errors occur, test DRAM with Motorola’s diagnostic firmware; replace faulty modules with same-spec ECC DRAM. For IP modules, reseat connections annually to prevent loose-contact failures.

Service and Guarantee Commitment

We back Motorola MVME 162-22 with a 90-day warranty for refurbished units, covering processor, memory, and interface defects. Each unit undergoes 24-hour stress testing (temperature cycling + I/O cycling) to meet original Motorola standards. Our 24/7 technical team assists with configuration (e.g., IP module setup) and troubleshooting (e.g., ECC error resolution). We also stock critical spares (batteries, DRAM) for next-day delivery, minimizing downtime. For users upgrading, we offer free consultation to pair Motorola MVME 162-22 with Emerson RSTi-EP adapters—ensuring legacy I/O works with modern systems.