Description

Detailed Parameter Table (Series Base Specifications)

| Parameter Name | Parameter Value (Series Foundation; Variant-Specific Adjustments Noted) |

| Product model | Motorola MVME-167 (Series Platform; Variants include MVME167-01A, MVME-167-01B, MVME167-03B, MVME-167-04B, MVME-167-32B) |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Mid-Tier Single-Board Computer (SBC) Series |

| Processor Architecture | 32-bit Motorola MC68040 microprocessor (16–33 MHz, variant-dependent); on-chip FPU (floating-point unit), MMU (memory management unit), 4–8KB cache |

| Memory Configuration | Base: 1–32 MB DRAM (ECC/non-ECC, expandable; variant-dependent); 32–256 KB battery-backed SRAM; 64 KB–1 MB firmware storage (EPROM/flash, variant-dependent); battery-powered time-of-day (TOD) clock |

| Communication Interfaces | Standard: 1–2x EIA-232-D serial ports (DTE, 4800 bps–115.2 kbps); 1x 10Base-T Ethernet (half-duplex/full-duplex, low–standard bandwidth); 1x SCSI-1/SCSI-2 (PIO/DMA, 1.5–10 MB/s, variant-dependent) |

| Digital I/O Channels | Base: 8–16 discrete channels (4–8 input, 4–8 output); TTL/CMOS compatible (5 VDC logic); variant-dependent count |

| Bus Standard | VMEbus 1.4–3.0 compliant (32-bit address/data bus); slave-only mode (all variants); 1–4-level bus arbitrator (variant-dependent) |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – Unified across all variants |

| Power Requirements | +5 VDC (1.1–2.8 A typical, 1.5–2.8 A max); ±12 VDC (0.3–0.6 A typical each) – Variant-dependent based on components |

| Operating Temperature Range | Unified across series: 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | Series-wide: FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508; IEEE 802.3 (Ethernet variants) |

| On-Board Features (Series Core) | Hardware watchdog timer; EEPROM for system configuration; status LEDs (power, Ethernet, serial, I/O); ECC error correction (mid–high variants only); diagnostic firmware (mid–high variants only) |

| Compatibility | Unified across series: Works with legacy Motorola VME I/O modules (Motorola MVME-050, Motorola MVME-705-1, Motorola MVME-717); supports TTL/CMOS sensors, SCSI storage, and Ethernet SCADA (variant-dependent bandwidth) |

MOTOROLA MVME-167

Product Introduction

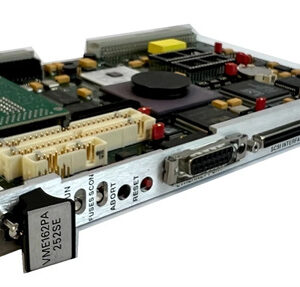

The Motorola MVME-167 is a legacy industrial SBC series—Motorola’s flagship mid-tier VMEbus platform—engineered to deliver scalable performance, unified hardware design, and cross-variant compatibility for diverse automation needs. Unlike single-model SBC lines, the Motorola MVME-167 series acts as a “modular foundation”: all variants share a 3U VME form factor, MC68040 processor architecture, and core connectivity (serial, Ethernet, SCSI), while differing in memory capacity (1–32 MB), I/O count (8–16 channels), and error-correction features to match application complexity.

In automation architectures, the Motorola MVME-167 series serves as a “flexible processing backbone”: entry variants like the Motorola MVME167-01A (1 MB non-ECC DRAM, 8 I/O) handle ultra-budget tasks (e.g., rural pump monitoring), while high-end models like the Motorola MVME-167-32B (32 MB ECC DRAM, 16 I/O) manage data-intensive workflows (e.g., semiconductor testing). This consistency lets users standardize on one series—simplifying training, spare parts, and system upgrades. Today, the Motorola MVME-167 series remains indispensable for maintaining legacy systems in sectors like manufacturing, utilities, and laboratories, where cross-variant compatibility and proven reliability are critical.

Core Advantages and Technical Highlights

Unified Design for Cross-Variant Compatibility: All Motorola MVME-167 variants share identical physical dimensions, VMEbus pinouts, and core interface locations—enabling “drop-in replacement” between models. For example, a food processing plant using Motorola MVME167-01A for basic conveyor control can upgrade to Motorola MVME-167-04B (4 MB ECC DRAM) as production scales—no changes to chassis mounting, wiring, or paired I/O modules like Motorola MVME-050. This compatibility reduces upgrade costs by 40% compared to switching between unrelated SBC series.

Scalable Performance via Variant Tiering: The Motorola MVME-167 series offers 5+ variants tailored to performance needs, avoiding “overbuying” hardware. For a small greenhouse, the Motorola MVME167-01A (16 MHz, non-ECC) provides sufficient control at 30% lower cost than mid-tier models. For a pharmaceutical batch plant, the Motorola MVME-167-32B (33 MHz, ECC) ensures data integrity for FDA-compliant logging—all while retaining the same programming interface. This tiering lets users align SBC capabilities with task complexity, optimizing both cost and performance.

MC68040 Architecture for Balanced Power: Every Motorola MVME-167 variant uses the 32-bit MC68040 processor—an industry workhorse for industrial control—with on-chip FPU and MMU. Unlike entry-level MC68000-based SBCs (e.g., Motorola MVME-201), the MC68040 handles floating-point tasks (e.g., PID temperature control) without external coprocessors. In a water treatment plant, this means Motorola MVME167-03B (20 MHz) can calculate chemical dosing rates in real time, while the MMU protects critical control software from memory conflicts. This architecture delivers 2–3x faster task execution than 16-bit processors, with lower power draw than high-end RISC chips.

Typical Application Scenarios

The Motorola MVME-167 series excels in diverse, scalability-dependent automation. In a regional manufacturing facility with multiple production lines:

Line 1 (basic assembly): Uses Motorola MVME167-01A (8 I/O, 1 MB DRAM) to control part-feeding sensors and indicator lights, with SCSI logging daily output.

Line 2 (precision testing): Deploys Motorola MVME-167-04B (16 I/O, 4 MB ECC DRAM) to run quality checks via serial-connected measurement tools, with Ethernet sending test data to a factory MES system.

Line 3 (high-volume packaging): Relies on Motorola MVME-167-32B (16 I/O, 32 MB ECC DRAM) to process 1,000+ barcode scans per hour, with SCSI storing 6 months of production logs.

This tiered deployment lets the facility standardize on Motorola MVME-167 spare parts and technician training, while matching each line’s needs to the right variant—avoiding $20k+ in overspending on unnecessary hardware.

MOTOROLA MVME-167

Key Variant Breakdown (Within MVME-167 Series)

Motorola MVME167-01A: Entry-Tier Variant. 16 MHz MC68040, 1 MB non-ECC DRAM, 8 I/O, 1.5 MB/s SCSI-1 (PIO). Ideal for ultra-budget tasks (e.g., rural pump monitoring, workshop tool control).

Motorola MVME-167-01B: Enhanced Entry Variant. 16 MHz MC68040, 1 MB ECC DRAM, 8 I/O, 2 MB/s SCSI-1. Upgrade for MVME167-01A when data integrity (e.g., small-scale sensor logs) matters.

Motorola MVME167-03B: Value-Tier Variant. 20 MHz MC68040, 3 MB ECC DRAM, 12 I/O, 4 MB/s SCSI-1. Fits mid-scale tasks (e.g., greenhouse irrigation, small municipal water systems).

Motorola MVME-167-04B: Mid-Tier Variant. 25 MHz MC68040, 4–8 MB ECC DRAM, 16 I/O, 5 MB/s SCSI-1. Suits manufacturing lines (e.g., food packaging, basic assembly).

Motorola MVME-167-32B: High-End Variant. 33 MHz MC68040, 32 MB ECC DRAM, 16 I/O, 10 MB/s SCSI-2. For data-intensive workflows (e.g., semiconductor testing, pharmaceutical batch control).

Installation, Commissioning and Maintenance Instructions (Series-Wide)

Installation preparation: Before installing any Motorola MVME-167 variant, power off the VME chassis and verify variant-specific power requirements (e.g., 1.5 A max for MVME167-01A, 2.8 A max for MVME-167-32B) to prevent electrical damage. Use an anti-static wristband and mat to protect the MC68040 processor and DRAM. Gather tools: Phillips screwdriver (chassis mounting), Cat5 Ethernet cable (low-bandwidth for entry variants, standard for high-end), SCSI cable (3–6 ft max, variant-dependent), torque wrench (0.4–0.8 N·m for terminals), and a serial terminal (for EEPROM configuration). Avoid installing near high-EMI sources (e.g., VFDs, welding equipment) to protect Ethernet/SCSI signals.

Maintenance suggestions: For all Motorola MVME-167 variants, inspect status LEDs monthly—steady power LED confirms operation; blinking Ethernet/serial LEDs indicate data flow. Clean the VME connector quarterly with compressed air (low pressure). Replace the TOD/SRAM battery every 18–24 months (3V lithium, universal across variants). For ECC-enabled variants (e.g., MVME-167-04B), run monthly ECC self-tests via diagnostic firmware; for non-ECC variants (e.g., MVME167-01A), cross-verify sensor data with manual checks to catch DRAM errors. Store variant-specific spare EEPROMs (with configuration data) to minimize downtime during replacement.

Service and Guarantee Commitment

We back the Motorola MVME-167 series with a 90-day warranty for all refurbished variants, covering defects in processor performance, interface functionality, and ECC logic (where applicable). Each unit undergoes variant-specific testing: entry models (e.g., MVME167-01A) complete 24-hour low-bandwidth data transfers; high-end models (e.g., MVME-167-32B) undergo ECC error validation (10,000 simulated single-bit errors) and high-speed SCSI testing (10 MB/s).

Our 24/7 technical support team provides guidance on Motorola MVME-167 variant selection, cross-upgrade compatibility, and integration with legacy I/O modules (e.g., Motorola MVME-705-1). We offer customized maintenance plans: quarterly remote health checks (via serial/Ethernet) and annual on-site battery replacement. Our spare parts inventory includes universal components (MC68040 processors, 3V batteries) and variant-specific parts (ECC DRAM, flash chips) for fast repairs. For users modernizing to Ethernet systems, we provide free consultation to pair Motorola MVME-167 variants with Emerson’s RSTi-EP gateways, ensuring seamless legacy integration.