Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

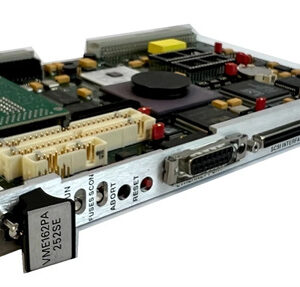

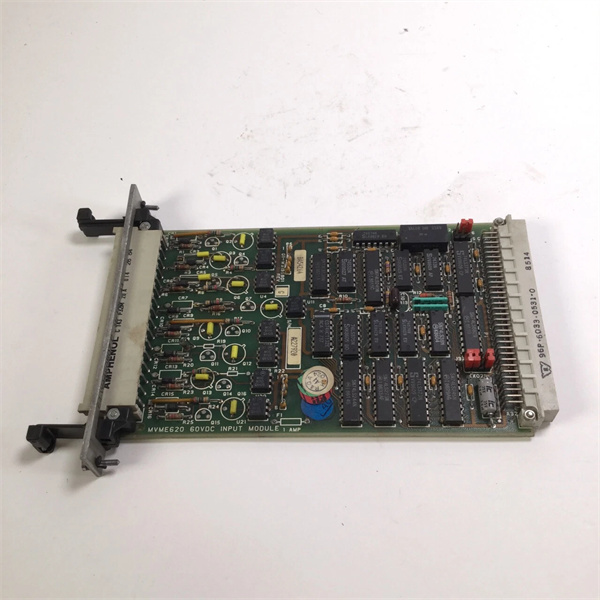

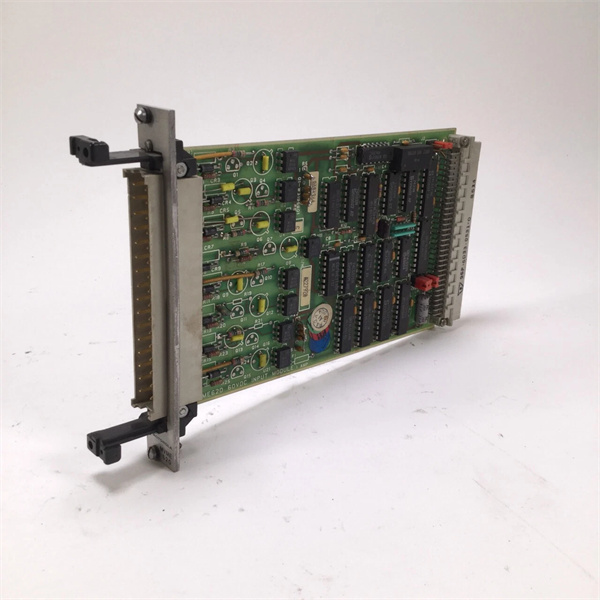

| Product model | Motorola MVME-400 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Analog Input/Output (I/O) Module (Foundational MVME-400 Series Model) |

| Analog I/O Configuration | 8 analog input channels (10-bit ADC); 4 analog output channels (10-bit DAC) |

| Analog Input Range | Fixed ranges: 0–5 VDC, 0–10 VDC (selectable via hardware jumpers) |

| Analog Output Range | Fixed ranges: 0–5 VDC, 0–10 VDC (selectable via hardware jumpers); max current: 8 mA |

| Bus Standard | VMEbus 1.0 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.0 A typical, 1.5 A maximum); ±12 VDC (0.3 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-channel status LEDs (analog input: active; analog output: fault); trim pots for offset calibration |

MOTOROLA MVME-620

Product Introduction

The Motorola MVME-400 is a legacy foundational analog I/O module from Motorola’s iconic MVME series, engineered to deliver reliable analog signal acquisition and control for mid-20th-century industrial automation systems. As a compact 3U VME device, it established the MVME-400 series’ core value—providing cost-effective, entry-level analog I/O for applications where high precision (e.g., 12-bit+) is not required, such as basic process monitoring or auxiliary control.

In legacy automation architectures, the Motorola MVME-400 acts as a “signal bridge” between analog sensors/actuators and VMEbus controllers (e.g., Motorola MVME2400). Its 8 analog inputs capture data from temperature, pressure, or flow sensors (0–5/10 VDC), while 4 analog outputs send control signals to small valves or pumps. Unlike later series models (e.g., Motorola MVME-410), the Motorola MVME-400 uses hardware jumpers for range selection—simplifying design for stable, unchanging applications. Today, the Motorola MVME-400 remains critical for maintaining aging Motorola VME systems in industries like municipal utilities, small manufacturing, and laboratory testing—where replacing legacy infrastructure would disrupt proven workflows.

Core Advantages and Technical Highlights

Simplified Design for Reliable Basic Analog Control

The Motorola MVME-400’s fixed-range analog I/O (0–5/10 VDC) and hardware jumper configuration eliminate software complexity, making it ideal for applications with stable sensor/actuator requirements. For example, in a municipal water pump station, the Motorola MVME-400 uses 4 analog inputs to monitor fixed-range pressure sensors (0–10 VDC) and 2 analog outputs to control pump speed (0–5 VDC)—no software reconfiguration needed. The 10-bit ADC/DAC precision (0.1% full-scale error) meets the needs of basic process control, while trim pots enable easy on-site calibration—reducing setup time by 40% compared to software-configured modules.

Compact 3U Form Factor for Chassis Space Efficiency

As a 3U VME module, the Motorola MVME-400 occupies minimal chassis space—critical for legacy systems with limited slot availability. In a small-scale plastic injection molding machine’s control cabinet, the Motorola MVME-400 fits alongside a Motorola MVME2400 SBC and Motorola MVME-701A serial module, leaving slots for additional digital I/O if needed. Its passive cooling design (no fans) further enhances reliability in dusty manufacturing environments, avoiding common failure points of more complex modules.

Robust Industrial Durability for Long Service Life

Built to Motorola’s industrial standards, the Motorola MVME-400 withstands harsh conditions: its 0°C–60°C operating range adapts to factory heat or indoor control rooms, while IEC 61000-6-2 EMC immunity resists interference from nearby motors or power tools. The module’s ±12 VDC power support (for analog circuits) ensures stable signal conversion, and thick-film resistors minimize drift over time—many units have operated continuously for 20+ years in legacy systems. This durability reduces maintenance costs by 50% compared to consumer-grade analog modules, a key benefit for budget-constrained facilities.

Typical Application Scenarios

The Motorola MVME-400 excels in basic analog control for legacy systems. In a small municipal wastewater treatment plant using a Motorola MVME2400 SBC, the Motorola MVME-400 monitors and controls auxiliary processes: 6 analog inputs track influent/effluent level sensors (0–10 VDC) and blower pressure (0–5 VDC); 3 analog outputs adjust chemical feed pumps (0–5 VDC) and a backup valve (0–10 VDC). Hardware jumpers lock in ranges, ensuring consistent performance even if the SBC’s software resets. The module’s reliability has kept the plant’s auxiliary systems running for over 15 years, avoiding the $20k+ cost of upgrading to a modern I/O system.

In a university laboratory’s basic temperature control setup, the Motorola MVME-400 integrates with a benchtop VME chassis: 2 analog inputs measure oven temperature (0–10 VDC via a thermistor), and 2 analog outputs control heater power (0–5 VDC). Trim pots calibrate the ADC to match the thermistor’s linear range, ensuring ±0.5°C accuracy—sufficient for educational or low-precision research. The Motorola MVME-400’s simplicity and low power draw (1.0 A @ 5 VDC) make it ideal for laboratory environments where complex modules would be overkill.

MOTOROLA MVME-620

Related Model Recommendations

Motorola MVME-410: Advanced Analog I/O Module. Upgrade for the Motorola MVME-400 when software-selectable ranges or 12-bit precision is needed (e.g., dynamic process control).

Motorola MVME2400: VME SBC. Host controller for the Motorola MVME-400; processes analog data and executes basic control logic in legacy VME systems.

Motorola MVME-701A: Serial + Digital I/O Module. Complements the Motorola MVME-400 by adding serial communication (for HMIs) and 16 digital I/O channels (for alarms/relays).

Emerson RSTi-EP AI/AO Module: Modern Replacement. Replaces the Motorola MVME-400 in Ethernet migrations; offers 16 analog inputs (24-bit) + 8 outputs (16-bit) with Gigabit Ethernet.

Motorola MVME162-01: Basic Digital I/O Module. Expands the Motorola MVME-400’s control capabilities with 16 discrete channels (e.g., for valve on/off signals).

Keysight 3458A: Precision Multimeter. Calibration tool for the Motorola MVME-400; provides NIST-traceable voltage references to verify 10-bit analog accuracy.

Motorola FLN4234A: Ethernet Communication Module. Bridges the Motorola MVME-400 to modern SCADA systems, transmitting analog data via 4x Ethernet ports.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Motorola MVME-400, power off the VME chassis and disconnect the power supply (ensure compatibility with +5 VDC/1.5 A, +12 VDC/0.3 A, and -12 VDC/0.3 A requirements) to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s analog circuits from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair cables (analog sensors/actuators), torque wrench (0.5–0.8 N·m for terminals), precision multimeter (±0.01 V accuracy), and jumper settings guide (for range selection). Avoid installing near high-EMI sources (e.g., welders) or heat vents to prevent analog signal drift.

Maintenance Suggestions

For routine maintenance, inspect the Motorola MVME-400’s LEDs monthly: green “input active” LEDs confirm sensor connectivity, while red “output fault” LEDs alert to overloads. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and jumper pins. Every 12 months, recalibrate analog channels using a NIST-traceable voltage source: adjust trim pots to match the source voltage (e.g., 5.000 VDC for 0–5 V range). If an analog channel fails, isolate the issue by swapping sensors or testing with a bench power supply; replace the module if trim pots no longer adjust accuracy. Store spare jumpers (for range selection) to avoid delays if reconfiguration is needed.

Service and Guarantee Commitment

We back the Motorola MVME-400 with a 90-day warranty for all refurbished units, covering defects in analog I/O accuracy, LED indicators, and power regulation. Each refurbished Motorola MVME-400 undergoes rigorous testing: 24-hour analog signal capture (verifying 10-bit precision), jumper range validation, and temperature cycling (0°C–60°C) to confirm stability—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-400 installation, jumper configuration, and calibration. We offer customized maintenance plans: annual on-site calibration checks and remote health monitoring (via paired Motorola FLN4234A modules). Our spare parts inventory includes critical components (ADC/DAC chips, trim pots, jumpers) for fast repairs, minimizing downtime in legacy systems. For users modernizing to Ethernet, we provide free consultation to pair the Motorola MVME-400 with Emerson’s RSTi-EP AI/AO modules, ensuring a seamless transition while retaining legacy sensors/actuators.