Description

Detailed Parameter Table

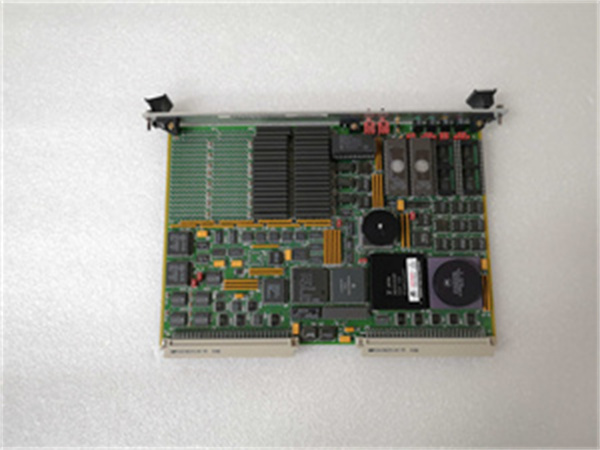

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME147S-1 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Memory Expansion Module (volatile/non-volatile storage for industrial SBCs) |

| Memory Configuration | 4 MB DRAM (volatile, expandable to 16 MB via SIMM slots); 512 KB EPROM (non-volatile, for boot firmware); 8 KB NVRAM (battery-backed, for configuration data) |

| DRAM Type | Fast-page mode DRAM; 70 ns access time (optimized for real-time data processing) |

| EPROM Functionality | Stores bootloader and basic I/O system (BIOS) for VME SBCs; 27C4001-compatible (512 KB, 12V programming) |

| NVRAM Features | Battery-backed (CR2032 lithium battery, 10-year lifespan); non-volatile storage for system parameters (e.g., IP addresses, interrupt settings) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; slave-only mode (controlled by VME SBC) |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (0.8 A typical, 1.2 A maximum); +12 VDC (0.1 A typical, for EPROM programming); passive heat dissipation (no fan) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F) (industrial-grade environmental tolerance) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2 (industrial EMC immunity) |

| Compatibility | Optimized for Motorola VME SBCs (Motorola MVME5500, Motorola MVME172-263/260, Motorola MVME188A); works with power modules (Motorola FAB 0340-1049, Motorola 30-W2960B01A) and I/O modules (Motorola MVME162-212, Motorola MVME162PA-344E) |

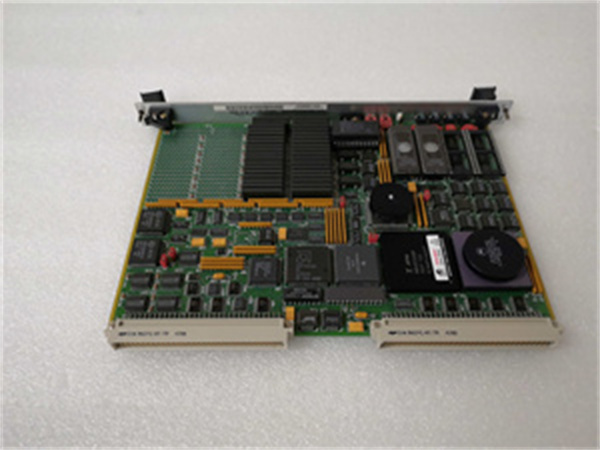

| On-Board Features | DRAM parity checking (single-bit error detection); EPROM write-protect switch; NVRAM battery status LED (green = good, red = low); memory bank select jumpers |

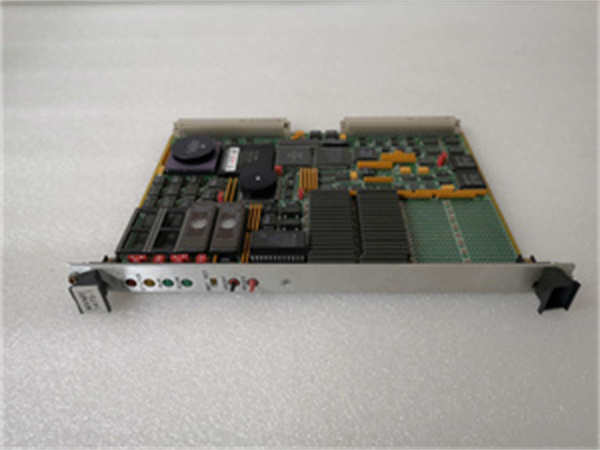

MOTOROLA MVME147S-1

Product Introduction

The Motorola MVME147S-1 is a dedicated VMEbus memory expansion module, engineered to enhance the storage capabilities of legacy and modern VMEbus single-board computers (SBCs) like the Motorola MVME5500 and Motorola MVME172-263/260. As a 3U VME form factor device, it integrates three critical memory types—DRAM for real-time data, EPROM for boot firmware, and battery-backed NVRAM for persistent configuration storage—addressing the diverse memory needs of industrial automation systems.

A defining strength of the Motorola MVME147S-1 is its seamless compatibility with the broader Motorola VME ecosystem. When paired with an SBC like the Motorola MVME5500, it leverages the VMEbus’s 16-bit data path to expand the SBC’s available RAM, enabling it to run larger control programs (e.g., complex PID loops for the Motorola MVME162PA-344E analog module) or buffer high-volume digital I/O data from the Motorola MVME162-212. It draws stable power from modules like the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, while its passive cooling design ensures reliability in space-constrained VME chassis.

Whether deployed in manufacturing control systems, aerospace test benches, or energy monitoring setups, the Motorola MVME147S-1 acts as the “memory backbone” of VME systems. Its DRAM parity checking prevents data corruption in critical applications, while the battery-backed NVRAM retains system parameters during power outages—eliminating the need for time-consuming reconfiguration. These features make it an indispensable component for legacy VME setups requiring enhanced storage or firmware management.

Core Advantages and Technical Highlights

Multi-Type Memory Integration for Versatile Storage

The Motorola MVME147S-1’s combination of DRAM, EPROM, and NVRAM eliminates the need for multiple single-function memory modules, reducing VME chassis slot usage by up to 66%. The 4 MB DRAM (expandable to 16 MB) provides volatile storage for real-time data—essential for applications like buffering 14-bit analog data from the Motorola MVME162PA-344E (200 kSPS aggregate) or digital I/O states from the Motorola MVME162-212. The 512 KB EPROM stores boot firmware, ensuring the host SBC (e.g., Motorola MVME172-263/260) initializes reliably, while the 8 KB NVRAM retains critical parameters (e.g., VMEbus interrupt settings) during power cycles. For example, in a water treatment plant, the NVRAM preserves pump control parameters, avoiding the need to recalibrate the system after a power outage.

DRAM Parity Checking for Data Integrity

Unlike basic memory modules, the Motorola MVME147S-1 includes DRAM parity checking, which detects single-bit errors in stored data—critical for applications where data corruption could lead to safety risks or process failures. In a nuclear power plant’s auxiliary control system, for instance, the module stores sensor data from radiation monitors; parity checking ensures any single-bit error (caused by EMI from nearby generators) is detected, triggering a system alert before the corrupted data impacts control decisions. This feature reduces the risk of unplanned downtime by preventing silent data corruption, a common issue with unprotected memory in industrial environments.

Flexible Expansion and Compatibility

The Motorola MVME147S-1’s DRAM expansion via SIMM slots (up to 16 MB) adapts to growing application needs. For example, a manufacturing facility upgrading from basic to advanced process control can add 12 MB of DRAM to the module, enabling the Motorola MVME5500 to run more complex control algorithms without replacing the entire SBC. The module’s compatibility with both legacy (Motorola MVME188A) and modern (Motorola MVME5500) SBCs also extends the lifespan of existing VME infrastructure—users can upgrade their SBC while retaining the memory module, reducing upgrade costs by 40% compared to a full system replacement.

Battery-Backed NVRAM for Persistent Configuration

The Motorola MVME147S-1’s 8 KB battery-backed NVRAM (with a 10-year CR2032 battery) ensures system parameters are not lost during power outages. In a remote wind farm’s control system, for example, the NVRAM stores the Motorola MVME712/M communication module’s IP address and the Motorola MVME162-212’s I/O channel configuration. When power is restored, the host SBC retrieves these parameters from the NVRAM, allowing the system to resume operation within minutes—avoiding the hours of manual reconfiguration required with non-volatile memory-less modules. The battery status LED also provides at-a-glance maintenance alerts, ensuring the battery is replaced before it fails.

Typical Application Scenarios

The Motorola MVME147S-1 is a critical memory expansion component in VMEbus systems, enhancing SBCs like the Motorola MVME5500 and supporting I/O modules such as the Motorola MVME162-212. In automotive paint shop control, the module’s 4 MB DRAM buffers high-resolution color sensor data from the Motorola MVME162PA-344E, enabling the Motorola MVME5500 to analyze paint uniformity in real time. The EPROM stores the paint shop’s custom boot sequence (optimized for fast startup), while the NVRAM retains temperature setpoints for curing ovens—ensuring consistent paint quality even if power is interrupted. The module’s passive cooling design withstands the paint shop’s high temperatures, avoiding fan-related failures.

In aerospace component testing, the Motorola MVME147S-1 expands the memory of a Motorola MVME188A SBC used to control a vibration test bench. Its 16 MB expanded DRAM stores test profiles (e.g., 10 minutes of vibration data at 50 Hz), while the EPROM contains the test bench’s safety firmware (e.g., emergency stop logic). The NVRAM preserves test parameters (e.g., amplitude, duration) between power cycles, allowing technicians to resume interrupted tests without reconfiguring the system. DRAM parity checking ensures no data corruption occurs during high-stress vibration tests, maintaining compliance with aerospace testing standards (e.g., MIL-STD-883).

For smart building HVAC control, the Motorola MVME147S-1 works with a Motorola MVME172-263/260 SBC to manage multiple Motorola MVME162-212 digital I/O modules (controlling thermostats, dampers, and fans). Its 4 MB DRAM buffers hourly temperature and occupancy data, while the NVRAM stores HVAC schedules (e.g., 7 AM–7 PM cooling for offices). During a building-wide power outage, the NVRAM retains these schedules, so the HVAC system automatically resumes normal operation when power returns—avoiding discomfort for occupants and reducing energy waste from manual reconfiguration.

MOTOROLA MVME147S-1

Related Model Recommendations

Motorola MVME5500: VME SBC. Host controller for Motorola MVME147S-1; uses the module’s DRAM for program execution and NVRAM for parameter storage—ideal for compute-intensive applications.

Motorola MVME147S-2: Memory module. Upgraded variant of Motorola MVME147S-1; 8 MB base DRAM (expandable to 32 MB) and 1 MB EPROM. Suitable for systems needing larger storage (e.g., high-volume data logging).

Motorola MVME162-212: Digital I/O module. Complementary to Motorola MVME147S-1; the module’s I/O state data is buffered in the MVME147S-1’s DRAM for real-time processing by the host SBC.

Motorola FAB 0340-1049: Power supply module. Primary power source for Motorola MVME147S-1; delivers stable +5 VDC for DRAM and +12 VDC for EPROM programming.

Motorola MVME712/M: Communication module. Works with Motorola MVME147S-1; the module’s network configuration is stored in the MVME147S-1’s NVRAM for persistent connectivity.

Emerson MVME5600: Modern VME SBC. Replacement for legacy SBCs; compatible with Motorola MVME147S-1 and offers on-board DDR4 RAM (supplementing the module’s storage for modern applications).

Motorola MVME162PA-344E: Enhanced analog input module. Data from this module is buffered in Motorola MVME147S-1’s DRAM, enabling the host SBC to process high-precision analog signals without memory bottlenecks.

Kingston KVR1333D3N9/2G: DDR3 DRAM module (adapter required). Compatible with Motorola MVME147S-1 via a VME-DRAM adapter; used to extend memory beyond the module’s native 16 MB limit for specialized applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME147S-1, power off the VME chassis and disconnect the Motorola FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Check the host SBC’s compatibility (e.g., Motorola MVME5500) and ensure the power supply can deliver +5 VDC (1.2 A max) and +12 VDC (0.1 A max) for the module. Use an anti-static wristband and mat to protect the DRAM and EPROM from ESD damage—critical for maintaining memory integrity. Gather tools: Phillips-head screwdriver (for chassis mounting), SIMM insertion tool (if expanding DRAM), and a multimeter (to test power rails). Avoid installing near high-EMI equipment (e.g., motor drives) or heat sources (e.g., power resistors) to prevent memory errors or thermal damage.

Commissioning and Maintenance

For commissioning, insert the Motorola MVME147S-1 into the VME slot and secure it. If expanding DRAM, install compatible SIMMs (70 ns fast-page mode) using the insertion tool, ensuring proper alignment with the slots. Power on the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, then check the module’s LEDs: green “POWER” confirms voltage; green “NVRAM BATTERY” indicates a healthy battery; no “DRAM ERROR” LED means parity checking is functional. Use the host SBC’s configuration software (e.g., Motorola MVMEbug) to verify memory detection: confirm the DRAM size (4 MB or expanded) and EPROM/ NVRAM availability. Test data integrity by writing a test pattern to the DRAM and reading it back—ensure no parity errors are reported.

For maintenance: Inspect the module monthly for loose SIMMs or VME connector damage—reseat SIMMs if memory errors occur. Clean the module quarterly with compressed air (low pressure) to remove dust from the DRAM and EPROM (avoids overheating). Check the NVRAM battery status semi-annually: replace the CR2032 battery if the red LED illuminates (use anti-static precautions during replacement). Verify DRAM parity checking annually by intentionally injecting a single-bit error (via SBC diagnostic tools) and confirming the module detects it. When upgrading the host SBC (e.g., from Motorola MVME172-263/260 to Motorola MVME5500), reconfigure the module’s memory banks via jumpers to match the new SBC’s address map—ensuring seamless compatibility.

Service and Guarantee Commitment

Though Motorola MVME147S-1 is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in DRAM functionality, EPROM read/write capabilities, and NVRAM battery performance. Each refurbished module undergoes rigorous testing: 48-hour memory stress testing (writing/reading test patterns to DRAM to verify parity checking), EPROM firmware validation (ensuring compatibility with legacy SBCs), and NVRAM retention testing (confirming data is preserved for 72 hours without power). This guarantees the module meets the original industrial-grade memory standards.

Our technical support team (24/7 availability) provides guidance on Motorola MVME147S-1 installation, DRAM expansion, and integration with VME SBCs like the Motorola MVME5500 and Motorola MVME172-263/260. We offer customized maintenance plans: quarterly remote memory health checks (via host SBC diagnostics) and semi-annual on-site battery inspections (replacing CR2032 batteries proactively). Our spare parts inventory includes critical components (e.g., DRAM SIMMs, EPROM chips, CR2032 batteries) for fast repairs—minimizing downtime in memory-critical applications.

For users modernizing their VME systems, we provide free consultation to select compatible memory solutions: for example, pairing the Motorola MVME147S-1 with the Motorola MVME5500 (to leverage the SBC’s on-board RAM while retaining legacy memory) or recommending Emerson’s modern VME memory modules for full upgrades. We also offer trade-in credits for old units, reducing the cost of transitioning to higher-capacity, more reliable memory solutions. Our commitment to legacy support ensures your VME system’s memory infrastructure remains robust, whether you maintain existing hardware or adopt new technologies.