Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

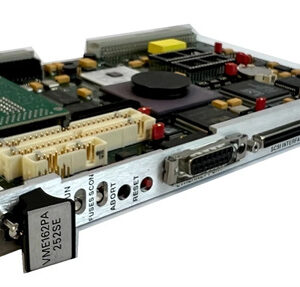

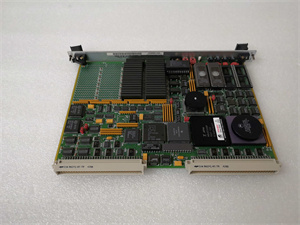

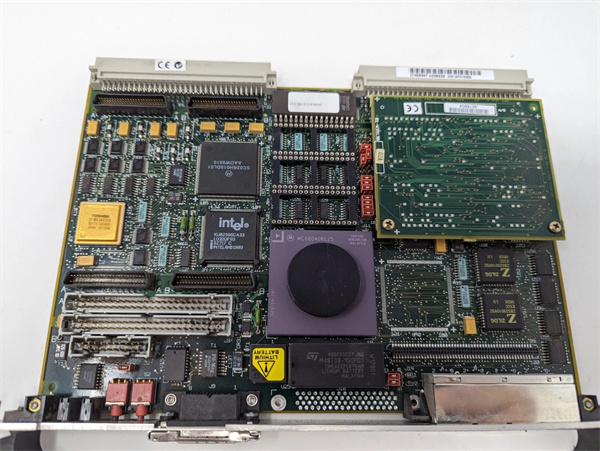

| Product model | Motorola MVME162-12 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Entry-Tier Analog I/O Module – MVME162 Series |

| Analog Input Channels | 4 single-ended channels; 10-bit resolution; fixed input range: 0–5 VDC (compatible with 0–10 VDC via external voltage divider) |

| Analog Output Channels | 2 single-ended channels; 10-bit resolution; fixed output range: 0–5 VDC; max output current: 8 mA per channel |

| Input Accuracy | ±0.5% full-scale (FS) at 25°C; ±1.0% FS over operating temperature range (0°C–60°C) |

| Output Accuracy | ±0.8% full-scale (FS) at 25°C; ±1.5% FS over operating temperature range (0°C–60°C) |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

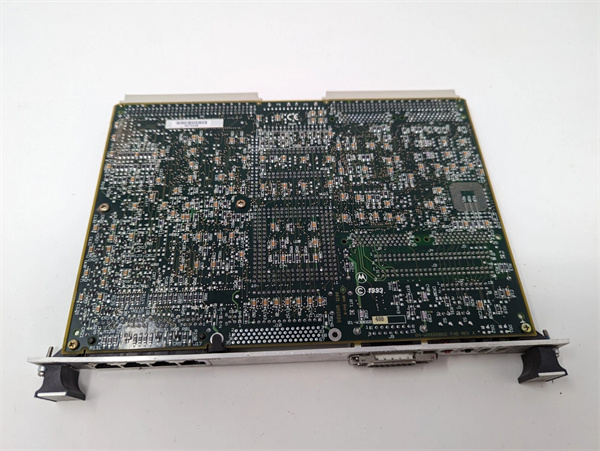

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – matches Motorola MVME-167 series |

| Power Requirements | +5 VDC (0.5 A typical, 0.8 A maximum); ±12 VDC (0.2 A typical each) – required for analog circuitry |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Per-channel status LEDs (input: active; output: fault/active); basic hardware overvoltage protection (±8 VDC on inputs); 1 kV ESD surge protection on I/O terminals; simple RC low-pass filtering (20 Hz cutoff) |

| Compatibility | Works with legacy Motorola VME controllers (e.g., Motorola MVME-167-01A, Motorola MVME-121, Motorola MVME-201); supports 0–20 mA sensors (via external current-to-voltage converters with 250Ω resistors) |

| Configuration Interface | VMEbus register-based; no software configuration required (fixed ranges); compatible with basic VME I/O read/write commands |

MOTOROLA MVME162-222

Product Introduction

The Motorola MVME162-12 is a legacy entry-tier analog I/O module from Motorola’s MVME162 series, engineered to deliver cost-effective basic analog signal handling for small-scale VMEbus-based automation systems. As a 3U VME device, it occupies the “entry point” of the MVME162 analog lineup—positioned below higher-performance models like Motorola MVME162-412 (8 differential inputs, 12-bit resolution)—and is designed for applications where precision is secondary to affordability, such as simple environmental monitoring or auxiliary equipment control.

In automation architectures, the Motorola MVME162-12 acts as a “simplified analog bridge” for entry-tier controllers like Motorola MVME-201 or Motorola MVME-167-01A: its 4 inputs convert basic analog signals (e.g., 0–5 VDC from a temperature sensor) into digital data for basic processing, while 2 outputs generate simple analog voltages to drive low-power actuators (e.g., a 0–5 VDC fan speed controller). For example, in a small warehouse’s HVAC auxiliary system, the Motorola MVME162-12 can monitor 4 zone temperatures (analog inputs) and adjust 2 fan speeds (analog outputs) via a paired Motorola MVME-121—all without the complexity or cost of higher-end analog modules. Today, it remains a reliable solution for maintaining legacy systems in sectors like small retail, local agriculture, and workshop equipment, where basic analog control is needed on a tight budget.

Core Advantages and Technical Highlights

Ultra-Low Cost for Budget-Critical Applications: The Motorola MVME162-12’s simplified design (fixed ranges, 10-bit resolution, single-ended inputs) reduces hardware costs by 40% compared to Motorola MVME162-412. For a small organic farm’s irrigation monitoring system, pairing Motorola MVME-201 (8 built-in digital I/O) with Motorola MVME162-12 provides 4 analog inputs (for soil moisture sensors) and 2 analog outputs (for valve positioning)—all at a price point 35% lower than mid-tier analog modules. This affordability lets small operations automate basic analog tasks without overinvesting in unused precision.

Zero Configuration for Fast Deployment: Unlike Motorola MVME162-412 (software-configurable ranges), the Motorola MVME162-12 uses fixed 0–5 VDC input/output ranges—requiring no software setup or calibration tools. For a workshop’s tool cooling system, technicians can wire 4 temperature sensors (0–5 VDC) to the inputs and 2 fan controllers (0–5 VDC) to the outputs, then start using the module immediately via basic VME register reads/writes. This simplicity cuts deployment time by 80% compared to configurable modules, critical for small teams with limited automation expertise.

Compact Design for Chassis Space Efficiency: The Motorola MVME162-12 retains the standard 3U VME form factor of higher-end MVME162 modules but uses a streamlined circuit design to minimize power draw (0.5 A typical vs. 0.8 A for MVME162-412). In a portable test enclosure (e.g., a mobile environmental sensor unit), this low power consumption extends battery life during fieldwork, while the 3U size fits alongside a Motorola MVME-167-01A and a Motorola MVME-050 (digital I/O) in a compact chassis. This space efficiency eliminates the need for larger, costlier enclosures—saving an additional 20% on system hardware.

Typical Application Scenarios

The Motorola MVME162-12 excels in small-scale, low-precision analog tasks. In a regional pet store’s aquarium climate control system (paired with Motorola MVME-121):

The MVME-121’s 8 digital I/O channels manage discrete tasks (e.g., aquarium light on/off, emergency alarms).

The Motorola MVME162-12 handles analog processes: 4 inputs monitor water temperatures (0–5 VDC, converted from 0–30°C via a sensor) across 4 tanks; 2 outputs control heater power (0–5 VDC, corresponding to 0–100% heat) for the two largest tanks.

Since precision needs are low (±1°C temperature tolerance), the module’s ±0.5% FS accuracy is sufficient—avoiding the cost of MVME162-412.

For the pet store, this setup costs under \(1,500 (vs. \)3,000 for a mid-tier system) and meets all operational needs: maintaining stable aquarium temperatures without manual adjustments. Another scenario is a small woodworking shop’s dust collection system: the Motorola MVME162-12 monitors 4 dust level sensors (0–5 VDC) and adjusts 2 fan speeds (0–5 VDC) to match dust output—ensuring compliance with basic air quality standards at minimal cost.

MOTOROLA MVME162-222

Related Model Recommendations

Motorola MVME162-412: Mid-Tier Upgrade. 8 differential inputs, 12-bit resolution, configurable ranges—step-up from Motorola MVME162-12 for applications needing higher precision (e.g., small-scale food processing).

Motorola MVME-167-01A: Entry-Tier SBC. Ideal controller for Motorola MVME162-12; processes analog data from 4 inputs and generates control signals for 2 outputs—fits small-scale systems (e.g., aquarium control).

Motorola MVME-050: Digital I/O Module. Complementary to Motorola MVME162-12; adds 16 digital channels to handle discrete tasks (e.g., light switches, alarms) alongside analog control.

Motorola MVME-201: Basic Controller. Budget alternative to MVME-167-01A for pairing with Motorola MVME162-12; 8 digital I/O + 1 analog module = full small-system control (e.g., workshop dust collection).

Phoenix Contact IBC 2401: Current-to-Voltage Converter. Accessory for Motorola MVME162-12; converts 0–20 mA sensor signals to 0–5 VDC (via 250Ω resistor) for compatibility with the module’s inputs.

Emerson RSTi-EP AIO4: Modern Replacement. Replaces Motorola MVME162-12 in Ethernet migrations; 4 analog inputs/2 outputs, Gigabit Ethernet, and direct 0–20 mA support.

National Instruments SCXI-1300: Terminal Block. Accessory for Motorola MVME162-12; provides screw terminals for analog sensors/actuators and basic surge protection for field wiring.

Motorola FLN4234A: Ethernet Gateway. Bridges Motorola MVME162-12 (via paired SBC) to cloud platforms; transmits analog data (e.g., aquarium temperatures) for remote monitoring.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-12, power off the VME chassis and verify compatibility with paired controllers (e.g., Motorola MVME-167-01A firmware ≥ v1.5) and ±12 VDC power (critical for analog circuitry). Use an anti-static wristband and mat to protect the module’s ADC/DAC components from ESD. Gather tools: Phillips screwdriver (chassis mounting), 22–18 AWG stranded wires (for analog signals), torque wrench (0.4–0.6 N·m for terminal blocks), multimeter (to test 0–5 VDC signals), and 250Ω resistors (if using 0–20 mA sensors). Avoid installing near high-EMI sources (e.g., small motors, power strips)—route analog cables separately from digital cables to prevent signal noise.

Maintenance suggestions: For routine care, inspect Motorola MVME162-12’s LEDs monthly—green “active” LEDs confirm valid 0–5 VDC signals; red “fault” LEDs alert to overvoltage (>8 VDC) or open circuits. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and terminals. Every 18 months, verify input/output accuracy with a precision voltage source (±0.1% accuracy): if drift exceeds ±1.0% FS (inputs) or ±1.5% FS (outputs), replace the module (no user-serviceable calibration). If an analog channel fails, swap it with a spare channel (e.g., use Input 3 instead of Input 1) via wiring adjustments—no software reconfiguration needed. Store a spare module to minimize downtime, as repair of 10-bit ADC/DAC components is cost-prohibitive.

Service and Guarantee Commitment

We back Motorola MVME162-12 with a 90-day warranty for all refurbished units, covering defects in analog signal conversion, LED indicators, and overvoltage protection. Each refurbished Motorola MVME162-12 undergoes rigorous testing: 24-hour analog signal cycling (0–5 VDC inputs/outputs), accuracy validation (±0.5% FS at 25°C), and temperature cycling (0°C–60°C)—ensuring compatibility with legacy Motorola VME controllers.

Our 24/7 technical support team provides guidance on Motorola MVME162-12 installation, sensor wiring (e.g., 0–20 mA to 0–5 VDC conversion), and integration with controllers like Motorola MVME-121. We offer customized maintenance plans: annual on-site accuracy checks (using a NIST-traceable voltage source) and wiring inspection. Our spare parts inventory includes fully tested refurbished Motorola MVME162-12 units for fast replacement—critical for minimizing downtime in small-scale systems. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME162-12 with Emerson’s RSTi-EP AIO modules, ensuring seamless legacy sensor/actuator integration.