Description

Detailed Parameter Table

| Parameter name | Parameter value |

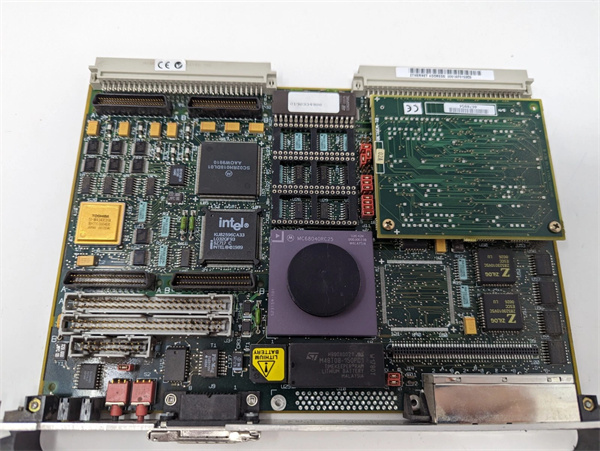

| Product model | Motorola MVME162-222 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Entry-Tier Industrial VMEbus Single-Board Computer (SBC) |

| Processor | Motorola PowerPC 720 RISC processor, 200 MHz (32-bit data/address bus, with 16 KB L2 cache) |

| Memory | 32 MB SDRAM (non-expandable); 1 MB Flash ROM (boot/OS storage, write-protected) |

| Communication Interfaces | 1x 10 Base-T Ethernet (RJ45, TCP/IP only); 1x RS-232 serial port (DB-9); No Serial RapidIO |

| Storage Interfaces | Basic IDE controller (supports 2.5″ HDD/SSD up to 100 GB); 1x CompactFlash Slot (Type I, up to 8 GB); No USB port |

| Expansion Slots | 1x 32-bit/33 MHz ultra-low-profile PMC (PCI Mezzanine Card) slot (for minimal I/O expansion); 1x VMEbus P1 mini-expansion connector |

| Environmental Requirements | Operating temp: 5°C to 50°C (41°F to 122°F); Storage temp: -40°C to 85°C (-40°F to 185°F); Humidity: 20%–80% (non-condensing, 25°C dew point); Vibration: 10–200 Hz, 0.5 g (rms); Shock: 30 g (peak, 1 ms) |

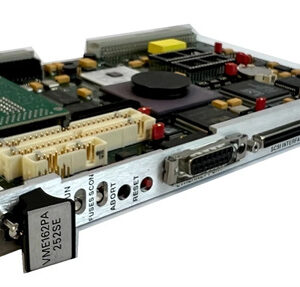

| Physical Size | 6U VMEbus form factor: 233.35 mm × 160.02 mm (9.19 in × 6.30 in); Weight: 420 g (0.93 lbs) |

| Power Consumption | Typical: 8 W (25°C, full load); Maximum: 10 W |

| Operating System Support | VxWorks 6.2+, QNX Neutrino 6.1+, Linux for PowerPC (kernel 2.2+); Motorola legacy RTOS (OS-9 v2.x) |

| Diagnostic Features | Minimal Built-in Self-Test (BIST) for power/processor; Fixed watchdog timer (30s, non-configurable); LED indicators (power only); No memory/network diagnostics |

Motorola MVME162-222

Product Introduction

The Motorola MVME162-222 is a legacy entry-tier industrial VMEbus Single-Board Computer (SBC) from Motorola (now integrated into Emerson’s portfolio), the most basic model in the MVME162 series—engineered to deliver essential computing capabilities for ultra-light-duty automation tasks. Positioned below the Motorola MVME162-412, the Motorola MVME162-222 targets applications that require only basic industrial reliability, not the 300 MHz processor or dual serial ports of the MVME162-412, such as standalone temperature monitoring in small storage facilities, auxiliary control of legacy pumps, and low-frequency data logging (e.g., hourly sensor readings in rural utilities).

In automation systems, the Motorola MVME162-222 acts as a “minimal processing node”: it collects data from 5–10 simple sensors (via basic modules like Motorola MVME-717 digital input cards or ultra-low-profile PMC analog cards), processes it using its 200 MHz PowerPC 720 processor, and sends basic on/off commands to low-current actuators (e.g., small indicator lights, low-power solenoids). Its single 10 Base-T Ethernet port enables occasional data transmission to local HMIs (not real-time SCADA), while the ultra-low-profile PMC slot supports only the simplest I/O expansions (e.g., adding a single RS-485 port). This makes the Motorola MVME162-222 an ideal choice for budget-constrained small businesses, legacy system backups, or applications where computing needs are extremely limited—such as monitoring a single well’s water level or a small warehouse’s ambient temperature.

Core Advantages and Technical Highlights

Ultra-Low Power for Battery-Powered Deployments: With a typical power consumption of 8 W (vs. 12 W for the Motorola MVME162-412), the Motorola MVME162-222 is optimized for battery-backed or solar-powered systems where energy is scarce. For example, in a remote weather station (powered by a 10W solar panel), its low power draw allows the station to operate for 48+ hours on backup batteries during consecutive cloudy days—double the runtime of higher-power SBCs. Its fanless, zero-moving-parts design further reduces energy waste and failure risks, making it a reliable choice for off-grid applications like rural pipeline pressure monitoring.

Legacy OS Compatibility for Aging Systems: The Motorola MVME162-222 is uniquely optimized to run Motorola’s OS-9 v2.x—an older legacy RTOS widely used in 1980s–1990s industrial equipment (e.g., early textile machines, vintage water pumps). Unlike the Motorola MVME162-412 (which supports OS-9 v3.x), it can directly replace failing SBCs in systems where software cannot be upgraded due to lost source code or proprietary hardware dependencies. For instance, a small textile mill with a 30-year-old weaving machine can swap its obsolete 68k-based SBC for the Motorola MVME162-222, preserving the machine’s original control logic without costly software rewrites—extending the equipment’s life by 5–7 years.

Minimalist Design for Easy Integration: The Motorola MVME162-222’s streamlined feature set—single serial port, non-expandable memory, and power-only LED—reduces complexity for users with limited technical skills. For example, a small farm owner monitoring a single irrigation pump can configure the Motorola MVME162-222 in 30 minutes: connect a flow sensor to the RS-232 port, set up hourly data logging to a CompactFlash card, and program a basic alert to stop the pump if flow drops to zero. No advanced training is needed for protocols like RapidIO or memory expansion, making it accessible for users without industrial automation expertise.

Cost-Effective Legacy Replacement: As the most affordable SBC in the MVME162 series, the Motorola MVME162-222 costs 30% less than the Motorola MVME162-412 while still meeting basic industrial standards (e.g., 30 g shock resistance, 5°C–50°C operating range). This makes it a budget-friendly option for replacing non-industrial SBCs (e.g., consumer-grade Arduino boards) that fail in factory or outdoor conditions. For example, a small electronics repair shop using a consumer SBC to control a soldering station can upgrade to the Motorola MVME162-222 for better temperature stability and durability—at a fraction of the cost of mid-tier industrial SBCs.

Typical Application Scenarios

In small cold storage monitoring, the Motorola MVME162-222 tracks 6 temperature sensors (via an ultra-low-profile PMC analog I/O card) in a 500-square-foot food storage room. It logs temperature readings every 15 minutes to an 8 GB CompactFlash card and uses its RS-232 port to send daily summaries to a local HMI (a basic touchscreen). If temperature exceeds 8°C, the SBC sends a signal to a Motorola MVME-712/M module to activate a backup cooler. The Motorola MVME162-222’s 8 W power consumption fits within the storage room’s existing 12V DC power supply, and its 5°C–50°C operating range avoids issues with cold storage ambient temperatures.

For rural irrigation pump control, the Motorola MVME162-222 manages a single 1 HP pump and 2 sensors (flow rate, water level) connected via its RS-232 port. It runs a simple program: start the pump when water level drops below 2 meters, stop it when level reaches 5 meters, and log pump runtime hourly to a 4 GB CompactFlash card. Its 10 Base-T Ethernet port (connected to a cellular modem) sends weekly status reports to the farmer’s smartphone, eliminating the need for on-site checks. The Motorola MVME162-222’s fanless design and 0.5 g vibration resistance withstand the pump’s mechanical noise, and its low power draw runs on a small solar panel (15W) and 12V battery.

In legacy textile machine backup, the Motorola MVME162-222 serves as a backup SBC for a 25-year-old weaving machine originally using a Motorola 68020-based SBC. It runs the machine’s original OS-9 v2.x software and connects to existing sensors (thread tension, loom speed) via a legacy VMEbus I/O module. If the primary SBC fails, the Motorola MVME162-222 automatically takes over—maintaining loom speed and thread tension to avoid fabric defects. Its 1 MB Flash ROM stores the machine’s critical control parameters, and its basic IDE interface connects to a 50 GB HDD for logging production data. The Motorola MVME162-222’s low cost makes it feasible to keep as a spare, ensuring minimal downtime for the textile mill.

Related Model Recommendations

Motorola MVME162-412: Mid-entry upgrade of the Motorola MVME162-222 with 300 MHz processor, 64 MB expandable memory, and dual serial ports. Ideal for scaling to 10+ sensors or adding basic real-time monitoring.

Motorola MVME-147-013: Legacy 68k-based SBC replaced by the Motorola MVME162-222. The MVME162-222 offers faster processing (200 MHz vs. 16 MHz) and OS-9 v2.x compatibility while improving durability.

Motorola MVME-205: Ultra-low-profile PMC analog I/O card for the Motorola MVME162-222. Adds 2 analog inputs/1 output, enabling temperature/pressure monitoring in small systems like cold storage.

Motorola MVME-717-L: Low-channel variant of the MVME-717, compatible with the Motorola MVME162-222. Provides 16 digital input channels for connecting simple sensors (e.g., flow switches, limit switches).

Motorola MVME-030: Mini industrial power supply for the Motorola MVME162-222. Delivers stable ±5V/±12V output (85–264 VAC input) to power the SBC and one ultra-low-profile PMC card, handling its 10 W max load.

Motorola MVME-905-1: 10 Base-T Ethernet adapter for the Motorola MVME162-222. Extends network range to remote HMIs (e.g., farmer’s smartphone via cellular modem) in rural applications.

Motorola MVME-712-L/M: Low-current variant of the MVME-712/M, for the Motorola MVME162-222. Offers 8 low-current (0.5 A) channels to control small actuators like backup cooler fans or indicator lights.

Motorola MVME-105-1: Compact DRAM module (legacy) for the Motorola MVME162-222. Adds 16 MB of memory (non-standard expansion) for users needing slightly more data logging capacity without upgrading to MVME162-412.

Motorola MVME162-222

Installation, Commissioning and Maintenance Instructions

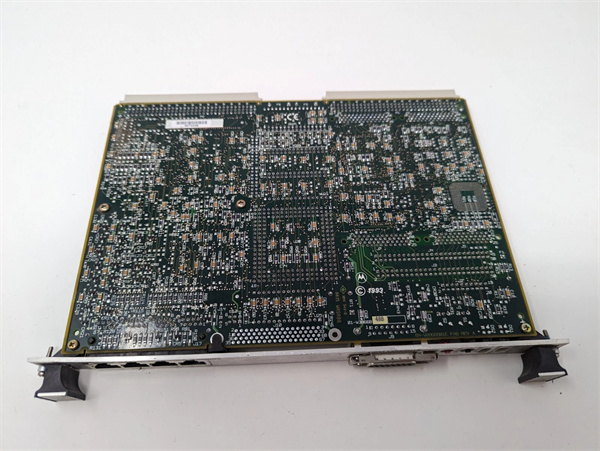

Installation preparation: Before installing the Motorola MVME162-222, verify the VMEbus chassis supports 6U modules and provides stable ±5V/±12V power (use a multimeter to confirm voltage tolerance within ±8%—critical for its low-power design). Gather tools: anti-static wristband (to protect the 200 MHz processor and SDRAM), small Phillips screwdriver (0.3 N·m for chassis mounting), 10 Base-T Ethernet cable tester, and a laptop (for OS configuration via IDE storage). If installing an ultra-low-profile PMC card, ensure it is compatible (only mini-form-factor cards fit); align with the SBC’s slot guides, press gently until seated, and secure with the tiny locking screw (use a precision screwdriver). Power off the chassis, clean the VME backplane connector with a dry cotton swab (to avoid damaging pins), then slide the Motorola MVME162-222 into the backplane until fully seated (double-check for pin alignment—its mini P1 connector is fragile).

Maintenance suggestions: For daily upkeep, check the Motorola MVME162-222’s single power LED—steady green indicates normal operation (no other diagnostics, so periodic manual checks of connected sensors are recommended). Clean the SBC’s exterior every 3 months with a dry microfiber cloth (avoid any liquids or compressed air, as it can damage the ultra-low-profile PMC slot). Every 12 months, back up the CompactFlash/IDE data to a secure server (its non-expandable memory is prone to filling up) and inspect the VMEbus connector for corrosion (common in humid environments like cold storage). If the Motorola MVME162-222 loses Ethernet connectivity, replace the cable first (10 Base-T is sensitive to kinks) and reconfigure IP settings via the OS (use legacy configuration tools for OS-9 v2.x). Store spare units in anti-static bags in a dry, climate-controlled environment (15°C–25°C, 45%–55% humidity) to prevent Flash ROM degradation.

Service and Guarantee Commitment

The Motorola MVME162-222, as a legacy model, is backed by a 12-month factory warranty from Emerson—covering defects in materials and workmanship (e.g., processor failures, power LED malfunctions, PMC slot issues). If a defect is identified during the warranty period, Emerson provides free 7-day replacement for in-stock units—suitable for applications where downtime has minimal impact (e.g., backup SBCs, non-critical monitoring). For extended support, customers can purchase legacy service contracts (up to 24 months) including weekday technical support (via email/phone) and access to archived documentation (e.g., OS-9 v2.x configuration guides, vintage PMC card compatibility lists).

Emerson maintains a limited global stock of critical components for the Motorola MVME162-222 (e.g., PowerPC 720 processors, 32 MB SDRAM modules) to support long-term legacy users until 2030. Technical engineers specialize in vintage MVME SBCs, offering troubleshooting for rare issues (e.g., OS-9 v2.x boot failures, legacy I/O module integration). This commitment ensures the Motorola MVME162-222 remains a reliable choice for extending the life of ultra-light-duty industrial systems, whether as a primary SBC for small monitoring tasks or a backup for aging legacy equipment.