Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME162-223 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Enhanced Digital Input/Output (I/O) Module (discrete signal control for industrial systems) |

| I/O Channel Configuration | 64 digital channels (32 input, 32 output); software-configurable per 16-channel bank (input/output direction selectable) |

| Input Signal Compatibility | TTL/CMOS compatible (5 VDC logic); input voltage range: 0–0.8 VDC (LOW), 2.0–5.5 VDC (HIGH); input current: 5 µA max per channel (lower than MVME162-212 for reduced power draw) |

| Output Signal Specifications | Push-pull outputs (vs. open-collector in MVME162-212); output voltage range: 0–5.5 VDC; output current: 30 mA source/sink per channel (150 mA per 16-channel bank) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; slave-only mode with interrupt vector support |

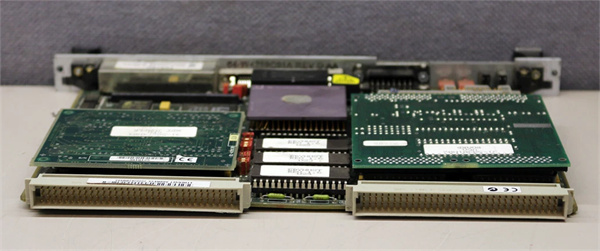

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); +12 VDC (0.2 A typical, for optional isolation); passive heat dissipation (no fan) |

| Operating Temperature Range | -10°C – 70°C (-14°F – 158°F) (extended industrial temperature tolerance vs. MVME162-212) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2 (industrial EMC immunity); UL 508 (industrial control equipment) |

| On-Board Features | Programmable edge/level-sensitive interrupts (per 16-channel bank); LED indicators (input state: green = HIGH, off = LOW; output enable: red = active); output short-circuit protection (200 mA max per channel); optional opto-isolation (250 Vrms channel-to-bus) |

| Compatibility | Optimized for Motorola VME SBCs (Motorola MVME5500, Motorola MVME172-263/260, Motorola MVME2434); works with power modules (Motorola FAB 0340-1049, Motorola 30-W2960B01A) and memory modules (Motorola MVME147S-1) |

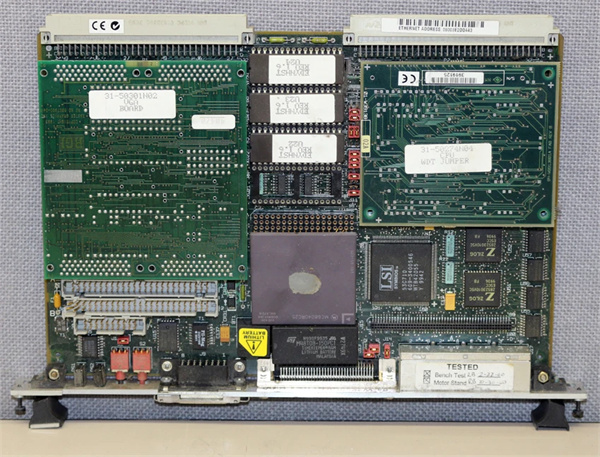

MOTOROLA MVME162-223

Product Introduction

The Motorola MVME162-223 is an enhanced VMEbus digital I/O module, representing an upgraded variant of the MVME162 series—engineered to deliver higher channel density and more robust signal handling than entry-level models like the Motorola MVME162-212. As a 3U VME form factor device, it integrates 64 configurable digital channels (32 input, 32 output) and push-pull outputs (vs. open-collector), making it ideal for industrial applications requiring high-density discrete control—from assembly line sequencing to machine safety interlocks.

A defining strength of the Motorola MVME162-223 is its seamless integration with the broader Motorola VME ecosystem. When paired with a high-performance SBC like the Motorola MVME5500, it leverages the VMEbus’s 16-bit data path to transmit real-time digital signals—critical for applications like coordinating multiple sensors and actuators in a packaging machine. It draws stable +5 VDC power from modules like the Motorola FAB 0340-1049 or Motorola 30-W2960B01A, while its extended temperature range (-10°C–70°C) expands its use to harsh environments—from cold storage facilities to hot factory floors.

Whether deployed in manufacturing, material handling, or automotive testing, the Motorola MVME162-223 acts as the “discrete control backbone” of VME systems. Its short-circuit protection safeguards both the module and connected devices, while programmable interrupts reduce CPU load by alerting the SBC only when critical channel states change. These features make it a superior choice to the Motorola MVME162-212 for high-density, high-reliability applications.

Core Advantages and Technical Highlights

High Channel Density for Space-Efficient Systems

The Motorola MVME162-223’s 64 channels (double the Motorola MVME162-212’s 32 channels) eliminate the need for multiple digital I/O modules, reducing VME chassis slot usage by 50%. This is critical for space-constrained environments, such as mobile industrial control cabinets or test benches with limited slots. For example, in a semiconductor wafer handling system, 32 input channels can monitor photoelectric sensors (detecting wafer presence), while 32 output channels control robotic grippers and conveyor motors—all managed by a single Motorola MVME162-223 module. The 16-channel configurable banks further adapt to changing needs: if the system is retooled for smaller wafers, 8 input channels can be reconfigured to output to control additional alignment actuators, no hardware replacement required.

Push-Pull Outputs for Direct Actuator Control

Unlike the Motorola MVME162-212’s open-collector outputs (which require external pull-up resistors), the Motorola MVME162-223 uses push-pull outputs that can both source and sink current (30 mA per channel). This enables direct control of low-power actuators—such as small DC motors, solenoid valves, or LED indicators—without additional driver circuits. For instance, in a food processing plant, the module’s push-pull outputs can directly power 24 VDC solenoid valves (via a voltage converter) to control product flow, eliminating the need for external relay modules. This simplifies wiring, reduces component count, and lowers overall system cost by 20–30% compared to open-collector-based setups.

Extended Temperature Range and Optional Isolation

With an operating temperature range of -10°C–70°C (vs. 0°C–60°C for the Motorola MVME162-212), the Motorola MVME162-223 operates reliably in extreme environments. In a cold-chain distribution center, it can monitor temperature-controlled storage doors (input channels) and activate alarm lights (output channels) even when cabinet temperatures drop to -5°C. For high-noise environments—such as near large motors or welding equipment—the module’s optional 250 Vrms opto-isolation prevents ground loops and EMI interference. In an automotive assembly line, this isolation ensures that welding-induced voltage spikes don’t corrupt sensor data from the module’s input channels, maintaining consistent production quality.

Short-Circuit Protection and Programmable Interrupts

The Motorola MVME162-223’s output short-circuit protection (200 mA max per channel) prevents damage to the module and connected devices if an output channel is accidentally shorted to ground. For example, if a worker accidentally cuts a wire to a conveyor motor, the module shuts down the affected channel, avoiding burnout of the output driver chip and minimizing downtime. The module’s programmable interrupts (edge/level-sensitive per 16-channel bank) further enhance efficiency: instead of the Motorola MVME5500 polling all 64 channels continuously, the module sends an interrupt only when a critical state changes (e.g., a safety door opening). This reduces CPU load by up to 40%, freeing the SBC to handle other tasks like processing analog data from the Motorola MVME162PA-344E.

Typical Application Scenarios

The Motorola MVME162-223 excels in high-density discrete control applications, working with SBCs like the Motorola MVME5500 and memory modules like the Motorola MVME147S-1. In automotive battery assembly lines, the module monitors 32 input channels (proximity sensors detecting battery cell placement, pressure sensors for welding tools) and controls 32 output channels (robotic grippers, welding electrodes, conveyor motors). The Motorola MVME5500 uses the module’s interrupts to trigger assembly steps—e.g., activating a welder only when a sensor confirms a cell is in place—reducing cycle time by 15%. The push-pull outputs directly power small gripper motors, eliminating external relays, while short-circuit protection prevents damage if a gripper jams.

In warehouse automated storage and retrieval systems (AS/RS), the Motorola MVME162-223 manages 24 input channels (photoelectric sensors tracking pallet positions, limit switches for crane travel) and 24 output channels (crane motors, lift mechanisms, indicator lights). Its extended temperature range (-10°C–70°C) withstands the cold of refrigerated warehouses, while optional isolation protects against EMI from nearby forklift chargers. The Motorola MVME147S-1’s NVRAM stores the module’s I/O configuration, ensuring the AS/RS resumes operation quickly after a power outage—critical for meeting order fulfillment deadlines.

For medical device manufacturing (e.g., syringe assembly), the Motorola MVME162-223 ensures compliance with safety standards: 16 input channels monitor safety interlocks (door switches, emergency stops), while 16 output channels control filling pumps, capping machines, and quality inspection cameras. The module’s short-circuit protection prevents pump damage if a tube clogs, while its low input current (5 µA) reduces power consumption—ideal for cleanroom systems powered by backup batteries. The Motorola MVME712/M transmits the module’s I/O states to a central MES system, enabling traceability of each syringe’s assembly process for FDA compliance.

MOTOROLA MVME162-223

Related Model Recommendations

Motorola MVME162-212: Legacy digital I/O module. Predecessor to Motorola MVME162-223; 32 channels, open-collector outputs. Suitable for low-density applications (e.g., small packaging machines) where cost is a priority.

Motorola MVME5500: VME SBC. Host controller for Motorola MVME162-223; configures I/O channels, processes interrupts, and executes control logic—critical for leveraging the module’s high density.

Motorola MVME162PA-344E: Enhanced analog input module. Complements Motorola MVME162-223 in hybrid systems; the Motorola MVME5500 uses analog data (e.g., temperature) to adjust digital outputs (e.g., activating a cooler).

Motorola MVME147S-1: Memory module. Stores Motorola MVME162-223’s I/O configuration and interrupt settings in NVRAM, ensuring persistence across power cycles.

Motorola FAB 0340-1049: Power supply module. Primary power source for Motorola MVME162-223; delivers stable +5 VDC (1.8 A max) to support the module’s 64 channels.

Emerson RSTi-EP DIO Module: Modern Ethernet-based digital I/O module. Replacement for Motorola MVME162-223 in systems migrating from VME to Ethernet; 64 channels, push-pull outputs, and compatibility with Motorola MVME5500 via Gigabit Ethernet.

Motorola MVME2434: High-performance VME SBC. Upgraded controller for Motorola MVME162-223 in compute-intensive systems (e.g., AS/RS with multiple modules); handles 64-channel data while running predictive maintenance algorithms.

Phoenix Contact QUINT-PS/1AC/24DC/5: Power supply. Converts 230 VAC to 24 VDC for actuators controlled by Motorola MVME162-223’s push-pull outputs, ensuring consistent actuator performance.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME162-223, power off the VME chassis and disconnect the Motorola FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the power supply can deliver +5 VDC (1.8 A max) and optional +12 VDC (0.2 A) for isolation. Use an anti-static wristband and mat to protect the module’s digital logic components from ESD damage—critical for maintaining push-pull output reliability. Gather tools: Phillips-head screwdriver (for chassis mounting), wire strippers (22–18 AWG wires for I/O connections), a multimeter (to test signal levels), and a torque wrench (0.5–0.8 N·m for terminal screws). Avoid installing near high-EMI equipment (e.g., variable-frequency drives) or heat sources (e.g., power resistors) to prevent signal interference or thermal damage.

Commissioning and Maintenance

For commissioning, insert the Motorola MVME162-223 into the VME slot and secure it. Wire input channels to sensors (e.g., proximity switches) and output channels to actuators (e.g., solenoids), ensuring correct polarity (5 VDC positive to signal, ground to common). If using optional isolation, connect +12 VDC to the module’s isolation power terminal. Power on the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, then check the module’s LEDs: green LEDs indicate HIGH input states, red LEDs confirm active outputs, and a yellow “ISOLATION OK” LED (if applicable) signals proper isolation. Use the Motorola MVME5500’s configuration software to set channel direction (input/output) per 16-channel bank and configure interrupts (edge/level-sensitive). Test functionality by toggling outputs from the SBC and verifying actuator response, then triggering inputs manually to confirm interrupts are detected.

For maintenance: Inspect the module monthly for loose I/O wiring or damaged connectors—tighten terminals and replace frayed wires to prevent intermittent signals. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and LED indicators. Verify output short-circuit protection semi-annually by intentionally shorting a channel (use a current-limited tool) and confirming the module shuts down the channel. If interrupts fail to trigger, check the Motorola MVME5500’s interrupt mask settings and verify the module’s VMEbus communication. When replacing the module, replicate the old unit’s channel configuration and interrupt settings to avoid disrupting system logic.

Service and Guarantee Commitment

Though Motorola MVME162-223 is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in I/O channel functionality, push-pull output performance, short-circuit protection, and interrupt capabilities. Each refurbished module undergoes rigorous testing: 24-hour I/O cycling (toggling all 64 channels to verify signal integrity), interrupt validation (ensuring correct SBC notification), and short-circuit protection testing (confirming channels shut down safely). This guarantees the module meets the original industrial-grade discrete control standards.

Our technical support team (24/7 availability) provides guidance on Motorola MVME162-223 installation, wiring, and integration with VME SBCs like the Motorola MVME5500. We offer customized maintenance plans: quarterly remote I/O state checks (via Motorola MVME712/M) and semi-annual on-site inspections (testing short-circuit protection, cleaning connectors). Our spare parts inventory includes critical components (e.g., push-pull output drivers, interrupt controllers) for fast repairs—minimizing downtime in high-density control applications.

For users modernizing to Ethernet systems, we provide free consultation to select compatible Emerson RSTi-EP DIO modules, ensuring seamless replacement of Motorola MVME162-223 while retaining existing sensors/actuators. We also offer trade-in credits for old units, reducing the cost of upgrading to modules with galvanic isolation and modern Ethernet connectivity. Our commitment to legacy support ensures your VME system’s digital I/O backbone remains reliable, whether you maintain existing infrastructure or transition to new platforms.