Description

Detailed Parameter Table

| Parameter name | Parameter value |

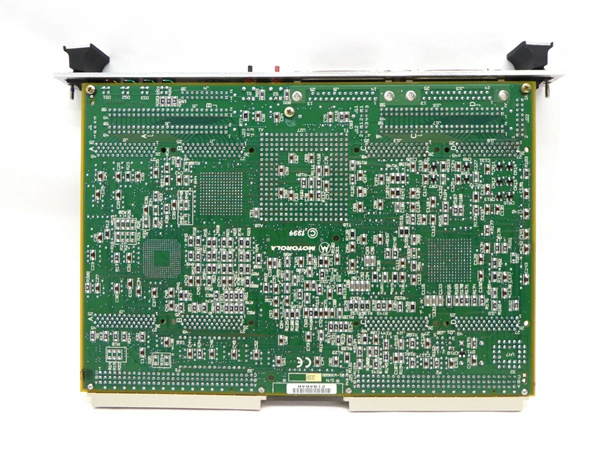

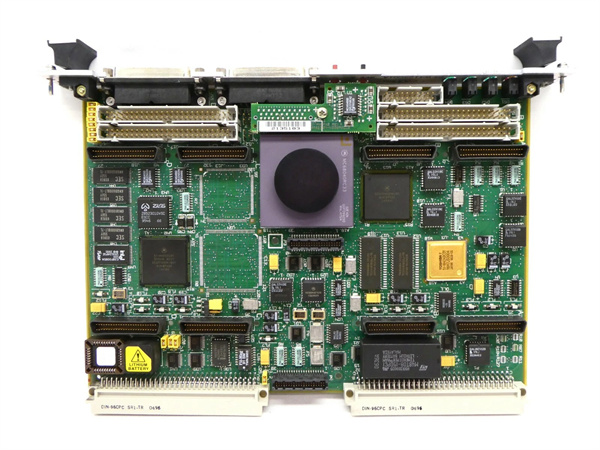

| Product model | Motorola MVME162-510 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Mid-Tier Real-Time Single-Board Computer (SBC) |

| Processor | 33 MHz Motorola MC68040 32-bit microprocessor; 8 KB L1 cache (4 KB instruction/4 KB data), MMU (Memory Management Unit); Optional FPU (Floating-Point Unit, factory-installable) |

| Memory Configuration | 16 MB shared DRAM (optional parity); 512 KB battery-backed SRAM (non-volatile); 1 MB Flash ROM (firmware + basic debugger support) |

| Communication Interfaces | 2x serial ports (1x EIA-232-D DTE console; 1x user-configurable EIA-232-D/EIA-422 DTE/DCE); Optional 10Base-T Ethernet (16-bit DMA) |

| Expansion Interfaces | 3x 16-bit Industry Pack® ports (1x DMA channel for 2 ports); VMEbus A32/D32 master/slave (IEEE 1014-1987 compliant) |

| Environmental Ratings | Operating temperature: -15°C–65°C (5°F–149°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.8 g (rms); Shock: 60 g (peak, 1 ms) |

| Physical Dimensions | Double-high 6U VME form factor: 233.4mm × 160mm × 29mm (9.19in × 6.30in × 1.14in); Weight: 760 g (1.68 lbs) |

| Power Consumption | Typical: 20 W (25°C, no Industry Pack modules, no FPU); Maximum: 32 W (all Industry Pack ports active, FPU installed) |

| Diagnostic Features | LED indicators (power, processor activity, Ethernet link, DRAM status, FPU active); VMEbus interrupt handler (5-stage); Configurable watchdog timer (1 ms–10 s) |

| Compatible Peripherals | Motorola IP-320 (16-bit analog I/O Industry Pack), Motorola MVME341A (serial module), Motorola MVME-177-003 (analog input), Motorola IP-485 (RS-485 Industry Pack) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME162-510

Product Introduction

The Motorola MVME162-510 is a legacy industrial VMEbus mid-tier real-time SBC designed to balance enhanced processing and flexible expansion for 1990s-era medium-complexity automation tasks—filling the gap between the entry-level Motorola MVME-162-531 (limited I/O, no FPU) and advanced Motorola MVME-162-532A (built-in FPU, 4 Industry Pack ports). Unlike its entry-level predecessor, Motorola MVME162-510 offers a faster 33 MHz MC68040 processor, optional FPU, and 3 Industry Pack ports—enabling it to handle tasks like semi-automated process control that require more compute power than basic sensing.

As a versatile workhorse in Motorola’s VME lineup, Motorola MVME162-510 acted as a “scalable control hub” for industrial systems. It connected to diverse peripherals (e.g., Motorola IP-320 for analog I/O, Motorola IP-485 for long-distance serial links) via its Industry Pack ports and communicated with central controllers via optional Ethernet. For example, in a 1990s medium-scale plastic injection molding plant, Motorola MVME162-510 monitored temperature/pressure sensors (via analog I/O) and adjusted mold parameters—its optional FPU enabling precise calculations for melt flow optimization. Today, it remains critical for legacy systems where upgrading to Motorola MVME-162-532A is unnecessary but basic SBCs like Motorola MVME-162-531 lack sufficient capability.

Core Advantages and Technical Highlights

Optional FPU for Precision Tasks: Motorola MVME162-510’s factory-installable FPU lets users add floating-point capability only when needed—avoiding the fixed cost of Motorola MVME-162-532A’s built-in FPU. A 1990s HVAC control system for a large office building used Motorola MVME162-510 with FPU to calculate heating/cooling load adjustments (based on occupancy and outdoor temperature) with ±0.5°C accuracy. Without the FPU, the system would require external calculators, adding complexity and latency—proving the value of this modular approach for budget-conscious users needing occasional precision.

Scalable I/O via 3 Industry Pack Ports: With 3 16-bit Industry Pack ports (vs. 1 port on Motorola MVME-162-531), Motorola MVME162-510 supports multi-function automation without chassis overcrowding. A 1990s beverage bottling line used Motorola MVME162-510 to connect 3 modules: Motorola IP-320 (fill level sensors), Motorola IP-485 (conveyor speed controllers), and Motorola IP-310 (bottling valve actuators). This setup handled 3 independent tasks via one SBC, reducing chassis slot usage by 60% vs. using separate controllers and simplifying wiring for maintenance teams.

Balanced Environmental Resilience: Motorola MVME162-510’s -15°C–65°C operating range and 60 g shock resistance exceed Motorola MVME-162-531’s 5°C–55°C range—making it suitable for semi-harsh environments like warehouse loading docks or outdoor equipment enclosures. A 1990s logistics center used Motorola MVME162-510 to control a refrigerated shipping dock: the SBC reliably monitored dock door status and refrigeration temperatures (down to -10°C) without component failure, while its vibration resistance handled forklift-induced mechanical stress. This resilience extended the SBC’s lifespan to 12+ years, outperforming more delicate entry-level models.

Typical Application Scenarios

In a 1990s medium-scale ceramic tile manufacturing plant, Motorola MVME162-510 controlled a glaze application system—paired with Motorola IP-320 (analog I/O for glaze viscosity sensors) and Motorola MVME341A (serial module for kiln temperature controllers). With the optional FPU installed, the SBC calculated glaze flow rates (based on tile speed and viscosity) to ensure uniform coating—reducing glaze waste by 25% vs. manual adjustments. Its 3 Industry Pack ports let the plant add a Motorola IP-485 module later to connect remote quality cameras, avoiding a full SBC upgrade. Motorola MVME162-510’s -15°C–65°C range withstood the plant’s warm (50°C) glaze room environment, ensuring consistent production.

For a 1990s municipal water treatment plant’s chemical dosing system, Motorola MVME162-510 managed 4 dosing pumps and 6 pH sensors. It used 2 Industry Pack ports for analog I/O (monitoring pH, controlling pump speed) and 1 port for an Motorola IP-485 module (sending data to a central SCADA system). The optional FPU enabled the SBC to run PID control loops for chemical dosage (adjusting based on real-time pH readings) with ±0.1 pH precision—meeting EPA water quality standards. Its battery-backed SRAM preserved dosing setpoints during power outages, while the watchdog timer reset the system gracefully if software glitched—minimizing unplanned downtime for critical water treatment processes.

Motorola MVME162-510

Related Model Recommendations

Motorola MVME-162-532A: Advanced sibling – Upgrade for Motorola MVME162-510 users needing built-in FPU, 4 Industry Pack ports, or DRAM parity (e.g., moving to regulated processes like pharmaceutical manufacturing).

Motorola MVME-162-531: Entry-level predecessor – Alternative for users with basic tasks (e.g., single-sensor monitoring) who don’t need Motorola MVME162-510’s speed or expansion.

Motorola IP-320: 16-bit analog I/O Industry Pack – Pair with Motorola MVME162-510 to add 16-channel analog input/output for sensor monitoring/actuator control (e.g., temperature, pressure).

Motorola FPU-68040: Factory-installable FPU – Add to Motorola MVME162-510 for floating-point calculations (e.g., HVAC load balancing, chemical dosing PID loops) when precision is required.

Emerson MVME162-510-R: Refurbished variant – Tested to original specs; Cost-effective replacement for failing Motorola MVME162-510 units in legacy medium-complexity systems.

Motorola MVME341A: High-speed serial module – Complement Motorola MVME162-510 with synchronous (SDLC/HDLC) communication for remote PLCs in industrial networks.

Motorola 30GD-2-U4300117: Industrial DC PSU – Powers Motorola MVME162-510 and Industry Pack modules, ensuring stable +5V/+12V for the MC68040 processor and optional FPU.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-510, verify the VME chassis supports double-high 6U modules and A32/D32 addressing. Confirm the power supply provides +5V DC (±5%) and +12V DC (±10%) – use a multimeter to check for ripple (<50mV if DRAM parity is enabled, <100mV otherwise). Gather tools: anti-static wristband (protects the MC68040 and optional FPU), torque screwdriver (0.5 N·m for 6U mounting), Industry Pack alignment tool, and FPU installation kit (if adding floating-point capability). Ensure Industry Pack modules are 16-bit (e.g., Motorola IP-320); 8-bit modules require adapters and will limit performance.

Maintenance suggestions: For daily upkeep, check Motorola MVME162-510’s LEDs – steady power, blinking processor/FPU activity, and no DRAM fault lights indicate normal operation. Test DRAM monthly via the host OS (run parity checks if enabled); replace DRAM if errors occur. Clean the module’s vents quarterly with compressed air (20 PSI max) – pay extra attention to the FPU heatsink if installed. Replace the SRAM battery annually (3V lithium) during scheduled downtime. Store spare Motorola MVME162-510 units in anti-static bags (15°C–25°C, 40%–60% humidity); if storing with FPU, include desiccants to prevent corrosion.

Service and Guarantee Commitment

Motorola MVME162-510 is backed by an 18-month warranty from Emerson for refurbished units, covering defects in the MC68040 processor, optional FPU, Industry Pack ports, and DRAM. If Motorola MVME162-510 fails (e.g., FPU malfunction in a chemical dosing system), Emerson provides free 7-day replacement – critical for medium-complexity systems where downtime disrupts production but does not risk regulatory non-compliance.

For extended support, customers can purchase a 36-month service contract, including weekday technical support (via phone/email), access to archived MC68040/FPU drivers (e.g., OS-9 v3.x), and remote troubleshooting for Industry Pack integration. Emerson maintains a global stock of MC68040 chips, optional FPUs, and 16 MB DRAM modules for Motorola MVME162-510 until 2038, ensuring legacy mid-tier systems remain operational. This commitment underscores Emerson’s dedication to supporting scalable industrial infrastructure and helping users avoid overinvesting in unnecessary advanced features.