Description

Professional Product Description for Motorola MVME162 – 512A

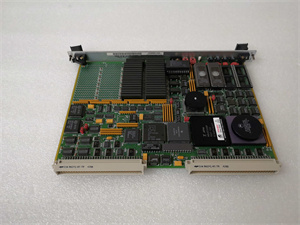

Motorola MVME162 – 512A is a high – performance embedded controller that has been widely applied in multiple industries. It is designed to meet the demanding requirements of various complex systems, offering reliable and efficient operation.

I. Product Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME162 – 512A |

| Manufacturer | Motorola (Now part of Emerson Industrial Automation) |

| Product Category | High – Performance Embedded Controller for Industrial Applications |

| Processor | MC68040 32 – bit microprocessor with a clock speed of 32 MHz; Equipped with a floating – point coprocessor for enhanced computational capabilities |

| Memory Configuration | 4 MB of DRAM for general data storage and processing; 512 KB of SRAM for quick access and caching; 1 MB of Flash memory for non – volatile storage of firmware and important data |

| Interface | VMEbus interface for seamless connection within VME – based systems; IndustryPack interface for easy expansion of functionality; Ethernet transceiver interface enabling network – based communication and data transfer |

| Dimensions | 6U VME module, fitting standard 6U VME chassis for convenient integration into existing setups |

| Input/Output Interface | Supports field input/output interface circuits, with opto – coupling for isolation and safety; Compatible with microcomputer input interface circuits |

| Communication Interface | Serial ports for traditional serial communication; E – NET (Ethernet) for high – speed network connectivity |

| Power Requirements | Input voltage: +5V DC (±5%) and other voltages as required by different components; Power consumption: varies according to usage scenarios, typically within a certain range to ensure stable operation |

| Environmental Ratings | Operating temperature: suitable for a wide range of temperatures, which may vary depending on specific industrial applications; Storage temperature: can withstand a relatively large temperature span during non – operation; Humidity: resistant to a certain level of humidity, ensuring reliable operation in different environmental conditions |

MOTOROLA MVME162-512

II. Product Introduction

The Motorola MVME162 – 512A is a flagship product in Motorola’s industrial control series. It is engineered to provide a powerful and stable computing platform for applications that demand high – speed data processing, reliable communication, and flexible expansion. Compared with some of its predecessors, the MVME162 – 512A features a more advanced processor and enhanced memory configuration, enabling it to handle more complex tasks with greater efficiency.

In the context of industrial automation, it serves as a central control unit, coordinating the operation of various devices and systems. For example, in a manufacturing plant, it can control the movement of robotic arms, monitor the production line speed, and manage the quality inspection process. In the communication field, it can be used to manage data routing and processing in network nodes, ensuring smooth data transmission. In military and aerospace applications, its high – reliability design makes it suitable for use in harsh environments, such as in aircraft avionics systems or military communication relays.

III. Core Advantages and Technical Highlights

Powerful Computational Performance

The 32 – MHz MC68040 processor, combined with a floating – point coprocessor, allows for extremely fast and accurate numerical calculations. This is crucial for applications such as complex motion control in robotics, where precise calculations of trajectories and forces are required. For instance, in a robotic assembly line, the MVME162 – 512A can calculate the optimal movement paths of robotic arms in real – time, reducing assembly errors and increasing production efficiency.

Rich Memory Resources

The 4 MB of DRAM provides sufficient space for running complex software applications and storing large amounts of data during operation. The 512 KB of SRAM offers fast access times, which is beneficial for caching frequently used data and instructions, thus speeding up the overall system operation. The 1 MB of Flash memory is used to store the system firmware, ensuring that the device can boot up quickly and stably. In an industrial monitoring system, the large DRAM can store historical sensor data for in – depth analysis, while the SRAM helps in quickly processing real – time sensor readings.

Versatile Interface Options

The VMEbus interface enables seamless integration with other VME – based modules, allowing for easy system expansion and configuration. The IndustryPack interface provides a standardized way to add additional functionality, such as analog – to – digital conversion, digital – to – analog conversion, or additional communication interfaces. The Ethernet transceiver interface enables high – speed network communication, making it possible to connect the device to a local area network or the Internet for remote monitoring and control. In a smart factory setup, the Ethernet interface can be used to send production data to a central server for analysis, while the IndustryPack interface can be used to connect specialized sensors for environmental monitoring.

High Reliability Design

Built with high – quality components and advanced manufacturing processes, the MVME162 – 512A is designed to operate reliably in harsh industrial environments. It can withstand temperature variations, humidity, vibration, and electromagnetic interference. In a power plant, where the environment is often harsh due to high temperatures and strong electromagnetic fields, the MVME162 – 512A can still operate stably, ensuring the normal operation of the power generation and distribution control systems.

MOTOROLA MVME162-512

IV. Typical Application Scenarios

Industrial Automation

In a large – scale automotive manufacturing plant, the MVME162 – 512A can be used to control the entire production line. It coordinates the movement of conveyor belts, the operation of robotic welding machines, and the quality inspection of assembled parts. For example, it can receive real – time sensor data from various parts of the production line, such as the position sensors on robotic arms and the quality inspection sensors on the assembly line. Based on this data, it can adjust the operation parameters of the equipment in real – time to ensure smooth production and high – quality products.

Communication Systems

In a telecommunication base station, the MVME162 – 512A can be used to manage data traffic and control the communication protocols. It can handle the incoming and outgoing data packets, ensuring efficient data transmission between the base station and mobile devices or other network nodes. For example, it can perform real – time data processing on the received signals, such as signal demodulation and error correction, and then forward the processed data to the appropriate destination.

Military and Aerospace

In an aircraft avionics system, the MVME162 – 512A can be used to control various functions, such as flight control, navigation, and communication. Its high – reliability design ensures that it can operate stably in the harsh environment of high – altitude flight, withstanding extreme temperatures, strong vibrations, and high – intensity electromagnetic radiation. For example, it can calculate the aircraft’s flight path based on the data from inertial navigation systems and GPS receivers, and then send control commands to the aircraft’s control surfaces to ensure safe flight.

V. Related Model Recommendations

MVME162 – 512

A related model with similar functionality but may have differences in some parameters. For example, it may have a different processor speed or memory configuration. It can be considered as an alternative for applications with less demanding computational requirements or when cost is a more critical factor.

MVME5500 Series

An upgraded series that offers enhanced performance features. It may have a more advanced processor, better memory management, and additional interface options. It is suitable for applications that require higher – level performance and more complex functionality, such as large – scale industrial control systems or high – end military applications.

VI. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installation, ensure that the VME chassis is compatible with the 6U VME module of the MVME162 – 512A. Check the power supply to ensure that it can provide the correct voltage and current required by the device. Gather the necessary installation tools, such as screwdrivers and anti – static wristbands. When connecting the interfaces, make sure to follow the correct wiring sequence to avoid short – circuits or incorrect connections.

Commissioning

After installation, power on the device and perform a basic self – test. Check the status indicators on the device to ensure that it is operating normally. Configure the communication interfaces, such as setting the IP address for the Ethernet interface and the baud rate for the serial ports. Test the functionality of the device by running some simple applications or sending test commands to ensure that all components are working properly.

Maintenance Suggestions

Regularly clean the device to prevent dust accumulation, which can affect heat dissipation and cause malfunctions. Check the power supply and cables periodically to ensure that there are no loose connections or signs of damage. Monitor the device’s performance, such as CPU usage and memory utilization, and perform software updates when available to improve stability and functionality. In case of hardware failures, replace the faulty components with original or compatible parts following the manufacturer’s instructions.

VII. Service and Guarantee Commitment

The Motorola MVME162 – 512A comes with a certain period of warranty, during which the manufacturer will be responsible for repairing or replacing any defective products. The manufacturer also provides technical support services, including online documentation, software updates, and technical consultation. In case of any problems with the device, customers can contact the manufacturer’s customer service department, and the manufacturer will strive to solve the problems in a timely manner to minimize the impact on the customer’s operations.