Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME162PA-344 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Analog Input Module (16-channel, industrial-grade signal acquisition) |

| Input Channel Count | 16 differential analog input channels (configurable for single-ended use) |

| Input Signal Range | ±5 VDC, ±10 VDC (software-selectable per channel); supports unipolar 0–5 VDC, 0–10 VDC via configuration |

| Resolution | 12-bit analog-to-digital converter (ADC); 0.024% full-scale accuracy (typical) |

| Sampling Rate | Up to 100 kSPS (aggregate); 6.25 kSPS per channel (sequential sampling) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; slave-only mode |

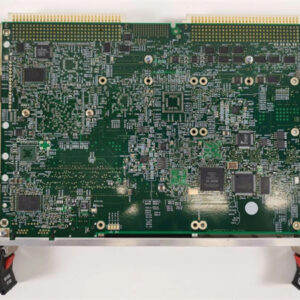

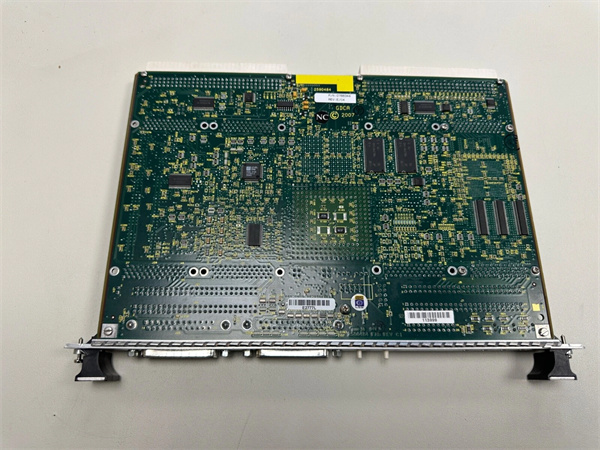

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.2 A typical, 1.5 A maximum); +12 VDC (0.3 A typical); -12 VDC (0.3 A typical); no external cooling required |

| Signal Isolation | Channel-to-channel isolation (250 Vrms); module-to-bus isolation (500 Vrms) – protects against ground loops |

| Calibration | On-board precision voltage reference; software-calibratable (no manual trim pots) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F) (industrial-grade; suitable for harsh environments) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; IEEE 1284 (optional parallel interface); FCC Class A (EMI); CE Mark; RoHS |

| On-Board Features | Programmable gain (1x, 2x, 4x, 8x); status LEDs for power and channel activity; watchdog timer synchronization |

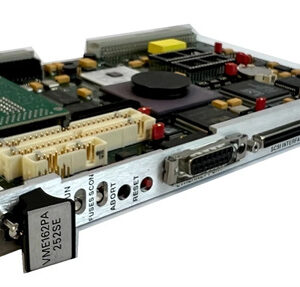

MOTOROLA MVME162PA-344

Product Introduction

The Motorola MVME162PA-344 is a high-performance VMEbus analog input module, designed specifically to complement Motorola’s MVME series single-board computers (SBCs) like the Motorola MVME172-263/260 in industrial automation systems. As a 3U VME form factor device, it excels at converting real-world analog signals (e.g., temperature, pressure, voltage) into digital data for processing by the host SBC—making it a critical component in data acquisition and closed-loop control applications.

A defining strength of the Motorola MVME162PA-344 is its 16 differential input channels, which minimize noise and ground loop interference common in industrial environments. With software-selectable signal ranges (±5 VDC, ±10 VDC) and programmable gain, it adapts to diverse sensor types, from pressure transducers in manufacturing to temperature probes in power plants. The module’s 12-bit ADC ensures precise data capture, while its VMEbus compatibility allows seamless integration with MVME SBCs—no additional adapters required.

Whether deployed in process control, condition monitoring, or test and measurement setups, the Motorola MVME162PA-344 delivers reliable signal acquisition. Its channel-to-channel isolation protects sensitive electronics from voltage spikes, while software calibration eliminates the need for manual adjustments—reducing maintenance time and ensuring consistent accuracy over the module’s lifespan. These features make it an ideal peripheral for legacy VME-based systems that demand high-quality analog data.

Core Advantages and Technical Highlights

High-Precision, Flexible Signal Acquisition

The Motorola MVME162PA-344’s 12-bit ADC and 0.024% full-scale accuracy ensure precise conversion of analog signals—critical for applications like semiconductor manufacturing, where even small voltage variations can impact product quality. Its 16 differential channels (configurable for single-ended use) and software-selectable ranges (±5 VDC, ±10 VDC) accommodate a wide array of sensors: for example, a ±10 VDC range can capture data from high-pressure transducers, while a 0–5 VDC range works with low-voltage temperature sensors. The programmable gain (1x–8x) further enhances versatility, allowing the module to detect small signal fluctuations (e.g., 10 mV changes in a 5 V signal) without external amplifiers.

Industrial-Grade Isolation and Noise Immunity

Ground loops and electromagnetic interference (EMI) are major challenges in industrial settings, but the Motorola MVME162PA-344 addresses this with 250 Vrms channel-to-channel isolation and 500 Vrms module-to-bus isolation. This protection prevents current from flowing between channels or the module and VMEbus, eliminating signal distortion caused by ground potential differences. For instance, in a factory with multiple power sources, the isolation ensures that a voltage spike in one sensor circuit won’t corrupt data from other channels. Additionally, the module’s EMI compliance (FCC Class A) minimizes interference from nearby motors or power lines, ensuring stable data capture even in noisy environments.

Seamless VMEbus Integration and SBC Compatibility

As a VMEbus slave module, the Motorola MVME162PA-344 integrates effortlessly with Motorola MVME SBCs like the Motorola MVME172-263/260. Its 16-bit VMEbus interface enables fast data transfer (up to 16 MB/s) to the host SBC, ensuring real-time processing of analog data—essential for closed-loop control applications (e.g., adjusting valve positions based on pressure readings). The module also supports watchdog timer synchronization with MVME SBCs: if the SBC’s watchdog timer triggers, the Motorola MVME162PA-344 pauses data acquisition to prevent invalid data from being processed, enhancing system reliability.

Software-Calibrated for Long-Term Accuracy

Unlike older analog modules that require manual trim pots, the Motorola MVME162PA-344 features software calibration using an on-board precision voltage reference. This allows technicians to calibrate the module remotely via the VMEbus, without disassembling the VME chassis—saving time and reducing downtime. The calibration process adjusts for ADC drift (caused by temperature changes or aging components), ensuring the module maintains accuracy over its lifespan. For example, in a power plant where the module operates at 60°C for extended periods, annual software calibration can restore any lost precision, avoiding costly errors in boiler pressure monitoring.

Typical Application Scenarios

The Motorola MVME162PA-344 is a workhorse in industrial environments where accurate analog signal acquisition is critical, often paired with SBCs like the Motorola MVME172-263/260. In chemical processing plants, it monitors key process variables: 16 differential channels capture data from pH sensors (0–5 VDC), temperature probes (±10 VDC), and flow meters (±5 VDC) across a reactor system. The module’s isolation protects against ground loops from chemical pumps, while its 12-bit resolution ensures precise pH readings (critical for avoiding chemical reactions). The host SBC uses this data to adjust chemical dosing rates, maintaining product quality and compliance with safety standards.

In wind turbine condition monitoring, the Motorola MVME162PA-344 is mounted in the turbine’s control cabinet, connected to vibration sensors (±10 VDC) on the gearbox and generator. Its 100 kSPS aggregate sampling rate captures high-frequency vibration data, which the SBC analyzes to detect early signs of wear (e.g., bearing damage). The module’s industrial temperature tolerance (0°C – 60°C) withstands the extreme temperatures inside turbine nacelles, while its software calibration ensures consistent data even as the turbine heats up during operation. This proactive monitoring reduces unplanned maintenance and extends turbine lifespan.

For automotive test benches, the Motorola MVME162PA-344 measures electrical signals from engine components: channels 1–4 capture voltage from fuel injectors (0–5 VDC), channels 5–8 monitor coolant temperature (±5 VDC), and channels 9–16 track exhaust gas sensors (0–10 VDC). The programmable gain (8x) amplifies small injector voltage changes, allowing engineers to detect fuel delivery inconsistencies. Paired with the Motorola MVME172-263/260, the module provides real-time data for optimizing engine performance and reducing emissions—critical for meeting automotive regulatory standards.

MOTOROLA MVME162PA-344

Related Model Recommendations

Motorola MVME162PA-342: Same MVME162PA series; 8-channel analog input module (vs. 16-channel for Motorola MVME162PA-344). Ideal for smaller systems (e.g., 4-turbine wind farms) where fewer sensors are needed, offering cost savings without sacrificing accuracy.

Motorola MVME162PA-346: 16-channel analog input module with 16-bit ADC (vs. 12-bit for Motorola MVME162PA-344). Upgrades precision for high-end applications (e.g., semiconductor wafer testing) where 0.006% full-scale accuracy is required.

Motorola MVME162-520: VMEbus analog input/output (I/O) module; 16 analog inputs + 8 analog outputs. Complements Motorola MVME162PA-344 in closed-loop control systems (e.g., chemical dosing) by adding output capability to adjust process variables.

Motorola MVME172-263/260: MVME172 Series SBC; 68040 CPU. Host SBC for Motorola MVME162PA-344, processing digital data from the module and executing control logic—essential for complete data acquisition and control systems.

Emerson MVME5500: Modern VMEbus SBC; PowerPC CPU. Replacement for legacy MVME SBCs, compatible with Motorola MVME162PA-344 to modernize systems with faster processing and Ethernet/IP connectivity.

Motorola MVME712M: VMEbus communication module; dual Ethernet ports. Transmits analog data from Motorola MVME162PA-344 (via host SBC) to remote SCADA systems (e.g., power plant control centers) for centralized monitoring.

Emerson RSTi-EP AI Module: Ethernet-based analog input module. Alternative for users migrating from VME to Ethernet; offers similar 16-channel, 12-bit performance and can interface with Motorola MVME162PA-344 via VME-Ethernet adapters.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola MVME162PA-344, power off the VME chassis and disconnect it from the main supply to avoid electrical shock. Verify the chassis supports 3U VME modules and that the power supply can deliver +5 VDC (1.5 A max), +12 VDC (0.3 A), and -12 VDC (0.3 A). Use an anti-static wristband and mat to protect the module’s ADC and isolation components from ESD damage. Gather tools: Phillips-head screwdriver (for chassis screws) and a VMEbus termination plug (if the module is the last in the slot). Ensure sensor wiring is shielded (to reduce EMI) and that differential channels are wired with twisted-pair cables (minimizes noise). Avoid installing near high-voltage equipment (e.g., transformers) to prevent signal interference.

Commissioning and Maintenance

For commissioning, power on the VME chassis and check the Motorola MVME162PA-344’s LEDs: a steady green “POWER” LED confirms proper voltage; blinking “ACTIVE” LEDs indicate channel data acquisition. Use the host SBC’s configuration software (e.g., Motorola’s MVMEbug) to set signal ranges (±5 VDC/±10 VDC) and gain (1x–8x) for each channel. Calibrate the module using the on-board reference: apply a known voltage (e.g., 5.000 VDC) to a channel, then run the software calibration utility to adjust the ADC for accuracy. Test data capture by connecting a sensor to a channel and verifying the digital output matches the expected value (e.g., a 25°C temperature probe should output ~2.5 VDC, converting to 25°C in the SBC software).

For maintenance: Clean the module quarterly with compressed air to remove dust from the heatsink (prevents overheating). Perform annual software calibration to correct ADC drift—use a precision voltage source (±0.001 V accuracy) for reference. Inspect sensor wiring bi-annually for damage (e.g., frayed shielding) and replace if needed to maintain noise immunity. If a channel fails to capture data, check the wiring first, then use the SBC’s diagnostic tools to verify the module’s VMEbus communication. When replacing the module, ensure the new Motorola MVME162PA-344 is calibrated to match the old module’s settings (e.g., gain, range) to avoid system inconsistencies.

Service and Guarantee Commitment

Though Motorola MVME162PA-344 is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in materials, workmanship, and isolation performance. Each refurbished module undergoes rigorous testing: 48-hour burn-in at 60°C to validate thermal stability, ADC accuracy checks (using a precision voltage source), and isolation resistance testing (to ensure 250 Vrms channel protection). This ensures the module meets the original industrial-grade standards.

Our technical support team (24/7 availability) provides guidance on Motorola MVME162PA-344 installation, calibration, and troubleshooting—including help with integrating it with MVME SBCs like the Motorola MVME172-263/260. We also offer customized maintenance plans: quarterly remote calibration checks (via VMEbus) and on-site wiring inspections to prevent noise-related issues. Our spare parts inventory includes critical components (e.g., ADC chips, isolation transformers) to minimize downtime if repairs are needed.

For users upgrading from VME to Ethernet systems, we provide free migration consultations—helping select compatible Emerson RSTi-EP AI modules and ensuring smooth integration with existing sensors. We also offer trade-in programs for old Motorola MVME162PA-344 units, reducing the cost of modernization while ensuring legacy systems remain operational during the transition. Our commitment to legacy support ensures your analog data acquisition needs are met, whether you maintain VME infrastructure or migrate to new platforms.