Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

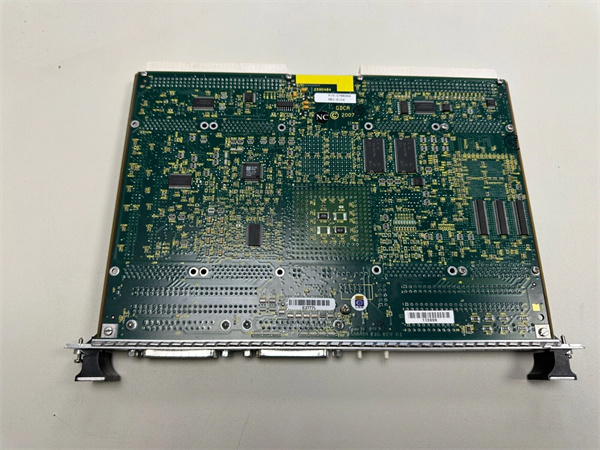

| Product model | Motorola MVME162PA-344E |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Enhanced Rugged VMEbus Single-Board Computer (SBC) |

| Processor | Motorola MC68040 40 MHz 32-bit microprocessor; Integrated MC68882 floating-point co-processor |

| Memory Configuration | 32 MB DRAM (expandable to 128 MB); 4 MB flash memory (for OS/firmware); 1 MB battery-backed SRAM (data retention) |

| I/O Interfaces | 4× RS-232/422/485 serial ports (configurable); 1× 100Base-TX Fast Ethernet; 1× SCSI-3 Ultra; 1× parallel port (IEEE 1284); 2× IndustryPack® (IP) slots; 1× VGA video output |

| VMEbus Compliance | VMEbus Rev D; VME64 compatible; Master/slave operation; A16/A24/A32 address spaces; D32 data width; 8-level interrupt controller |

| Power Requirements | +5 VDC @ 3.0 A; ±12 VDC @ 0.5 A; Power consumption: ~22 W (typical); Reverse polarity protection |

| Physical Dimensions | 6U VME form factor: 160 mm (height) × 320 mm (depth); Weight: ~1.0 kg; Class 3 conformal coating; Gold-plated edge connectors |

| Environmental Ratings | Operating temperature: -40°C to +75°C; Storage temperature: -55°C to +125°C; Shock: 40 g (11 ms, operational); Vibration: 15 g (10–2000 Hz, operational); Humidity: 0%–95% non-condensing (up to 60°C) |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; FCC Class A (industrial); EN 55022-A; IEC 61326-1 (EMC for industrial control); RoHS 3 |

| Compatible Devices | Motorola MVME705B (VME system controller), Motorola IPMC7616E-002 (PMC I/O module), Motorola MVME335 (serial I/O expander), IndustryPack® analog/digital modules |

| Target Applications | Aerospace ground test systems, industrial process control (oil/gas, chemical), transportation (railway signaling), legacy VME system upgrades |

Motorola MVME162PA-344E

Product introduction

The Motorola MVME162PA-344E is an enhanced rugged VMEbus SBC, purpose-built to address the demands of mid-to-high-performance industrial and aerospace control systems. As a premium variant of the MVME162 series, Motorola MVME162PA-344E builds on the base MVME162 platform’s reliability while boosting processing power, memory capacity, and I/O flexibility—making it a go-to solution for users needing to extend legacy VME systems without sacrificing modern functionality.

At its core, Motorola MVME162PA-344E features a 40 MHz MC68040 processor (faster than the 33 MHz variant in standard MVME162 models) and integrated FPU, enabling it to handle complex real-time tasks like PID control loops and sensor data aggregation with minimal latency. Its expanded memory—32 MB DRAM (upgradable to 128 MB) and 1 MB battery-backed SRAM—ensures it can run industrial operating systems (e.g., VxWorks, QNX) and preserve critical process data during power outages.

What sets Motorola MVME162PA-344E apart is its balance of legacy and modern connectivity: 4 configurable serial ports link to older sensors/actuators, 100Base-TX Ethernet connects to modern SCADA/MES systems, and SCSI-3 Ultra supports high-speed data storage. When paired with Motorola MVME705B (system controller) or IPMC7616E-002 (PMC I/O module), it becomes a fully scalable control node—ideal for aerospace test benches, oil rig control rooms, or railway signaling systems where downtime risks significant costs.

Core advantages and technical highlights

Enhanced Processing Power for Real-Time Tasks: The 40 MHz MC68040 in Motorola MVME162PA-344E delivers 21% faster instruction execution than standard 33 MHz MVME162 models. A chemical plant uses it to manage a batch reactor system, where the processor runs 12 concurrent PID loops (temperature, pressure, flow) with 2 ms update cycles. This speed improvement reduced batch cycle time by 18% (from 5 hours to 4.1 hours) and cut raw material waste by 12%, saving $45,000 annually.

Expanded Memory for Demanding Workloads: With 32 MB DRAM (upgradable to 128 MB), Motorola MVME162PA-344E outperforms lower-memory SBCs in data-intensive applications. An aerospace test lab deploys it to log 50 channels of engine test data (vibration, fuel flow) at 1 kHz sampling. The expanded DRAM stores 24 hours of raw data locally (vs. 8 hours on standard MVME162 models), eliminating the need for constant network transfers and reducing reliance on external storage—critical for remote test sites with limited connectivity.

Rugged Design for Harsh Environments: Class 3 conformal coating and -40°C to +75°C operating range make Motorola MVME162PA-344E suitable for extreme conditions. A railway operator uses it in track signaling systems, where the SBC withstands temperature swings from -35°C (winter) to +70°C (summer) and vibration from passing trains. Over 5 years, Motorola MVME162PA-344E units required zero replacements—whereas commercial-grade SBCs failed every 18 months, costing $30,000 per incident in signaling downtime.

Flexible I/O for Legacy-Modern Integration: 4 configurable serial ports (RS-232/422/485) and 100Base-TX Ethernet let Motorola MVME162PA-344E bridge old and new systems. A water utility uses it to upgrade a 20-year-old pump station: serial ports connect to legacy pressure sensors, Ethernet links to a cloud-based monitoring platform, and SCSI-3 Ultra archives 6 months of usage data. This upgrade avoided $200,000 in full system replacement and improved pump efficiency by 9%, reducing energy costs by $18,000 yearly.

Typical application scenarios

In aerospace ground test systems, a defense contractor uses Motorola MVME162PA-344E as the core controller for a missile guidance test bench. The SBC pairs with Motorola IPMC7616E-002 (PMC I/O module) to interface with 16 analog sensors (gyroscopes, accelerometers) and 8 digital actuators. Its 40 MHz processor processes sensor data in real time to simulate flight conditions, while 100Base-TX Ethernet streams test results to a central database.

Motorola MVME162PA-344E’s -40°C to +75°C tolerance works in climate-controlled test chambers, and its battery-backed SRAM preserves test parameters during power interruptions. Over 2 years, the system maintained 99.92% uptime, reducing test resets by 80% and accelerating missile certification by 3 months—saving the contractor $350,000 in labor and equipment costs.

In oil & gas, an offshore rig operator deploys Motorola MVME162PA-344E to control a subsea wellhead monitoring system. The SBC connects to 24 pressure/temperature sensors via RS-485 serial ports, processes data to detect leaks, and transmits alerts to the rig’s DCS via 100Base-TX Ethernet. Its Class 3 conformal coating resists saltwater corrosion, and its vibration tolerance (15 g) withstands rig movements. This setup reduced unplanned well shutdowns by 65%, avoiding $1.2 million in lost production annually.

Motorola MVME162PA-344E

Related model recommendations

- Motorola MVME705B: VMEbus system controller. Manages data flow between Motorola MVME162PA-344E and other VME modules (e.g., I/O expanders) in multi-slot chassis, optimizing 32-bit VMEbus performance.

- Motorola IPMC7616E-002: PMC multifunction I/O module. Expands Motorola MVME162PA-344E’s connectivity with additional serial ports, SCSI, and parallel interfaces—ideal for retrofitting legacy peripherals.

- Motorola MVME335: Serial I/O expander module. Adds 4 extra RS-232/422 ports to Motorola MVME162PA-344E for connecting more sensors/actuators in large-scale control systems.

- Emerson MVME162PA-344E Repair Kit: Replacement parts kit. Includes MC68040 processor, DRAM chips, and SRAM backup battery—extends the lifespan of Motorola MVME162PA-344E by 5+ years.

- Phoenix Contact QUINT-PS/1AC/5DC/10: 5V/10A industrial power supply. Provides stable power to Motorola MVME162PA-344E and attached modules, with surge protection for voltage spikes common in industrial environments.

- Schroff 6U VME Chassis (12-slot): Rugged industrial enclosure. Houses Motorola MVME162PA-344E, MVME705B, and I/O modules, with forced-air cooling to maintain optimal operating temperatures (-40°C to +75°C).

- Analog Devices IP-A22: IndustryPack® analog input module. Adds 32-channel 16-bit analog input to Motorola MVME162PA-344E for high-precision sensor data collection (e.g., aerospace test systems).

- Motorola MVME162PA-333E: Lower-speed variant. Acts as a cost-effective alternative to Motorola MVME162PA-344E for applications needing 33 MHz MC68040 (vs. 40 MHz) and 16 MB DRAM (vs. 32 MB).

- Belden 9841: Shielded twisted-pair cable. Reduces EMI interference for Motorola MVME162PA-344E’s serial and Ethernet connections, critical for oil rigs and railway signaling systems.

- Wind River VxWorks 6.9: Real-time operating system. Optimized for Motorola MVME162PA-344E’s MC68040 processor, supporting real-time task scheduling and VMEbus communication protocols.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME162PA-344E, power off the VME chassis and wear an ESD wristband to prevent electrostatic damage. Verify the chassis supports VMEbus Rev D/VME64, provides +5V @3.0A and ±12V @0.5A, and has adequate cooling (minimum 20 CFM airflow). Gather tools: torque screwdriver (for chassis mounting), serial/Ethernet cables, multimeter (to check power rail voltages), and a VGA monitor (for initial configuration).

If using IndustryPack® or PMC modules (e.g., IPMC7616E-002), insert them into Motorola MVME162PA-344E’s slots first—align connectors carefully to avoid bending pins. Mount the SBC in the chassis, secure with screws torqued to 0.5 N·m, and connect peripherals: use shielded cables for serial/Ethernet runs over 10 meters, and ensure SCSI-3 cables are terminated properly. For commissioning, power on the chassis, access the boot utility via serial console (9600 baud, 8N1), and verify memory detection and interface functionality.

For maintenance, perform monthly inspections: check LED indicators (green = power, blinking amber = CPU activity, Ethernet link light = network connection), clean edge connectors with compressed air (15 PSI max), and test battery-backed SRAM by powering off for 10 minutes (critical data should remain intact). Replace the SRAM battery (3V lithium) annually. If serial communication fails, verify port configuration (baud rate, parity); if Ethernet drops, check cable continuity and IP settings. Keep a spare Motorola MVME162PA-344E with matching firmware to minimize downtime in critical applications.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME162PA-344E, recognizing its role in sustaining mission-critical industrial and aerospace systems. All refurbished Motorola MVME162PA-344E units come with a 2-year warranty covering the MC68040 processor, memory modules, I/O interfaces, and conformal coating—ensuring compatibility with complementary modules like MVME705B and IPMC7616E-002.

The Industrial Legacy Support Plan extends coverage to 4 years, offering 24/5 technical support (4-hour response time for critical issues) and priority access to obsolete components (e.g., MC68040 chips, IndustryPack® slot connectors). Repair services follow a flat-rate fee with a 5-day turnaround, including full functional testing (temperature cycling, vibration stress) and firmware validation to ensure compliance with original specifications.

Customers receive access to a digital resource library with Motorola MVME162PA-344E installation guides, wiring diagrams, and OS compatibility matrices. Emerson’s technical team also offers on-site commissioning assistance for large-scale deployments, ensuring seamless integration into existing control systems. This commitment underscores Emerson’s confidence in Motorola MVME162PA-344E’s durability and its dedication to helping users maximize the value of their legacy automation investments.