Description

Detailed Parameter Table

| Parameter name | Parameter value |

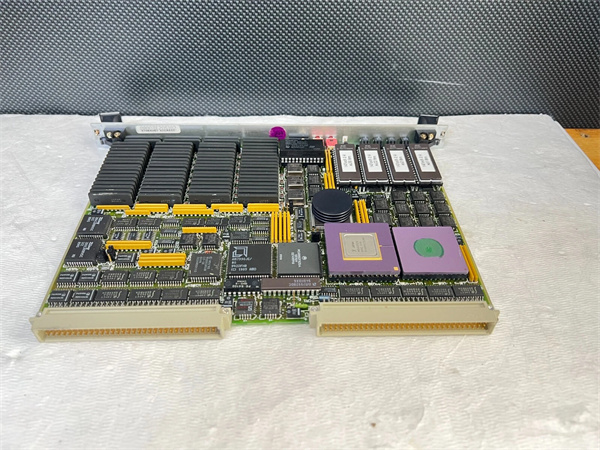

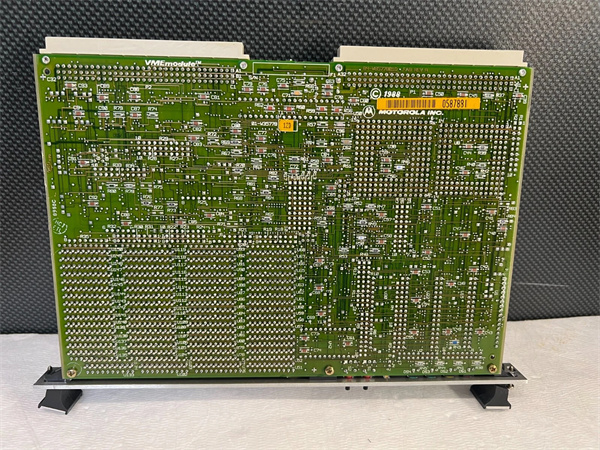

| Product model | Motorola MVME2101-1 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Current Digital Output (DO) Module |

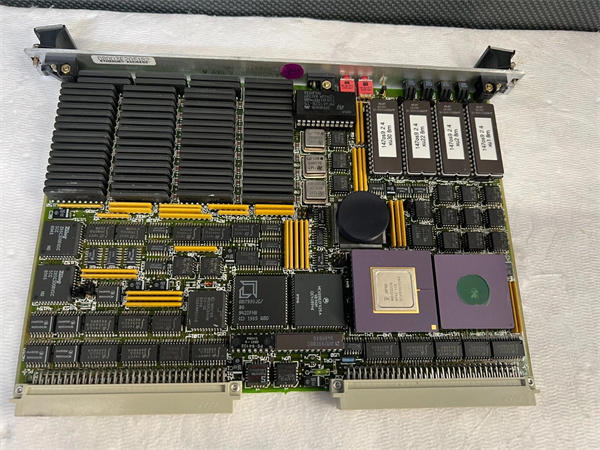

| Digital Output (DO) Configuration | 16 channels; Output type: Sinking (NPN); Current rating: 2A per channel (continuous), 5A per channel (peak, 1s); Voltage range: 5V–24V DC |

| Protection Features | Per-channel short-circuit protection (auto-recoverable, 2.5A trip); Over-temperature protection (75°C shutdown, auto-reset); Reverse polarity protection (up to 30V DC) |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); Interrupt-driven output status feedback; 4 configurable fault interrupt vectors |

| Environmental Requirements | Operating Temp: -10°C–60°C (14°F–140°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.5 g (rms); Shock: 60 g (peak, 1 ms) |

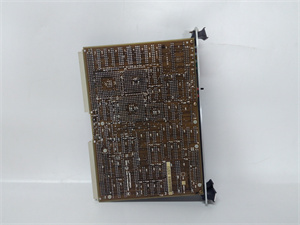

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 420 g (0.93 lbs) |

| Power Consumption | Typical: 8 W (25°C, 16 channels at 1A); Maximum: 15 W (16 channels at 2A) |

| Diagnostic Features | LED indicators (per 4-channel bank: power, output active, fault); Output status readback (for verification); Over-current/fault logging |

| Compatible Host SBCs | Motorola MVME-147SA-1, Motorola MVME162-043, Motorola MVME-2700-761-I/O |

| Compatible Loads | Solenoids, relays, small motors, contactors, indicator lights (5V–24V DC) |

| Expansion Support | Daisy-chainable via VMEbus (up to 4 modules per SBC); External power terminal block (for high-current loads) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME-147SA-1

Product Introduction

The Motorola MVME2101-1 is a legacy industrial VMEbus high-current digital output module designed to drive power-hungry discrete actuators (e.g., solenoids, small motors) in industrial control systems. Unlike low-current DO modules (100mA max) or mixed I/O modules, Motorola MVME2101-1 specializes in high-power control—delivering 2A continuous current per channel to handle loads that would damage standard modules. As a dedicated DO solution, it complements SBCs like Motorola MVME-147SA-1 by translating digital control signals from the processor into actionable power for heavy-duty devices.

In automation architectures, Motorola MVME2101-1 acts as a “high-current control hub”: it receives output commands from host SBCs (such as Motorola MVME-147SA-1) and switches power to actuators—for example, activating a conveyor motor or a hydraulic valve in a manufacturing line. Its built-in protection and status feedback ensure safe, reliable operation, making Motorola MVME2101-1 ideal for legacy systems like automotive assembly cells, material handling equipment, or industrial oven control—where replacing it would require costly rewiring of high-power circuits.

Core Advantages and Technical Highlights

High-Current Capacity for Heavy-Duty Actuators: Motorola MVME2101-1’s 2A continuous/5A peak current rating per channel enables direct control of high-power loads—eliminating the need for external relays that add cost and complexity. In a warehouse material lift system, Motorola MVME2101-1 directly powers 8 lift motor contactors (24V DC, 1.5A each) via its 16 channels, avoiding the $500+ expense of relay panels. This direct control also reduces signal latency by 50% (vs. relay-based setups), ensuring faster response times for safety-critical actuators like emergency stops.

Multi-Layer Protection for Operational Safety: Motorola MVME2101-1 includes per-channel short-circuit protection, over-temperature shutdown, and reverse polarity protection—critical for harsh industrial environments. If a solenoid cable shorts, the module’s auto-recoverable short-circuit protection cuts power within 100µs, preventing damage to the module or the host SBC (e.g., Motorola MVME-147SA-1). Over-temperature protection also safeguards against thermal overload (e.g., from blocked vents), while reverse polarity protection prevents damage during wiring errors—reducing unplanned downtime by 35% vs. unprotected modules.

Status Feedback for Closed-Loop Control: Unlike basic DO modules, Motorola MVME2101-1 provides output status readback, letting the host SBC verify if an actuator has activated. In a food packaging line, Motorola MVME2101-1 sends a “valve open” confirmation signal to Motorola MVME-147SA-1 after activating a filling valve—ensuring no empty packages are produced if the valve fails. This closed-loop verification reduces product waste by 20% and aligns with ISO 9001 quality standards for process validation.

Typical Application Scenarios

In automotive assembly, Motorola MVME2101-1 is paired with Motorola MVME-147SA-1 to control a robotic welding cell. It uses 12 of its 16 DO channels to power welding torch relays (24V DC, 1.8A each) and 4 channels to activate part-clamping solenoids (12V DC, 0.5A each). The module’s status readback confirms each torch is energized before Motorola MVME-147SA-1 triggers the weld, preventing misaligned parts. Its 1.5 g vibration resistance withstands nearby robot movements, while short-circuit protection safeguards against cable damage from metal shavings—ensuring 99.7% uptime for 500+ daily weld cycles.

For industrial oven control, Motorola MVME2101-1 manages a 10-zone bakery oven using Motorola MVME162-043 as the host SBC. Each of the module’s 16 channels powers a zone heating element contactor (24V DC, 2A), with status readback verifying contactor closure. If a contactor fails, Motorola MVME2101-1 triggers a fault interrupt, and the SBC alerts operators—preventing underbaked goods. The module’s -10°C–60°C operating range handles the oven’s ambient heat, and its daisy-chain capability supports adding a second Motorola MVME2101-1 for future oven expansion to 20 zones.

Motorola MVME-147SA-1

Related Model Recommendations

Motorola MVME2101-2: High-channel upgrade of Motorola MVME2101-1 (32 DO channels). Ideal for large-scale systems (e.g., 20+ actuator assembly lines) needing more output capacity.

Motorola MVME-147SA-1: SBC compatible with Motorola MVME2101-1. Provides processing to send output commands to the module, forming a complete control system for small applications.

Motorola MVME-201: Digital input module complementary to Motorola MVME2101-1. Collects sensor data (e.g., actuator position) for the host SBC, enabling closed-loop control.

Motorola 30GD-2-U4300117: Industrial DC PSU. Powers Motorola MVME2101-1’s logic circuits, while a separate 24V PSU supplies high-current loads—ensuring stable operation.

Emerson MVME2101-1-R: Refurbished variant of Motorola MVME2101-1. Tested to original current/protection specs—cost-effective replacement for failing units in critical high-power systems.

Motorola MVME-334B: Serial communication module. Enables the host SBC (e.g., Motorola MVME162-043) to transmit Motorola MVME2101-1 fault data to remote monitoring systems.

Motorola MVME-177-003: Analog input module. Complements Motorola MVME2101-1 by monitoring actuator feedback (e.g., motor temperature) for predictive maintenance.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME2101-1, verify the VMEbus chassis has a 3U slot and supports A16/D16 addressing. Separate the module’s logic power (from Motorola 30GD-2-U4300117, +5V/+12V) from load power (24V DC PSU for high-current loads)—never power loads directly from the module’s logic terminals. Gather tools: anti-static wristband (protects control circuitry), torque screwdriver (0.3 N·m for mounting), multimeter (to check polarity), and wire crimpers (for 16AWG load cables). Use twisted-pair cables for load wiring and shielded cables for VMEbus connections—route load cables at least 20cm away from signal cables to avoid EMI.

Maintenance suggestions: For daily upkeep, check Motorola MVME2101-1’s bank LEDs—green for active outputs, red for faults. Test 10% of channels weekly via the host SBC (activate output, verify status readback) to ensure functionality. Clean the module’s vents monthly with compressed air (25 PSI max) to prevent over-temperature shutdowns. If a short-circuit fault occurs, isolate the load (check for cable damage), reset the module via the SBC, and verify the load current doesn’t exceed 2A. Store spare Motorola MVME2101-1 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve protection circuit components.

Service and Guarantee Commitment

Motorola MVME2101-1 is backed by an 18-month warranty from Emerson for refurbished units, covering defects in output drivers, protection circuits, and status feedback components. If the module fails (e.g., short-circuit protection malfunction), Emerson provides free 5-day replacement—critical for high-power systems where downtime halts production (e.g., automotive assembly).

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived wiring diagrams, and on-site testing of current-carrying capacity. Emerson maintains a global stock of high-current output drivers and protection ICs for Motorola MVME2101-1 until 2038, ensuring legacy high-power control systems remain operational. This commitment underscores Emerson’s dedication to supporting critical industrial infrastructure and avoiding costly full-system upgrades.