Description

Detailed Parameter Table

| Parameter name | Parameter value |

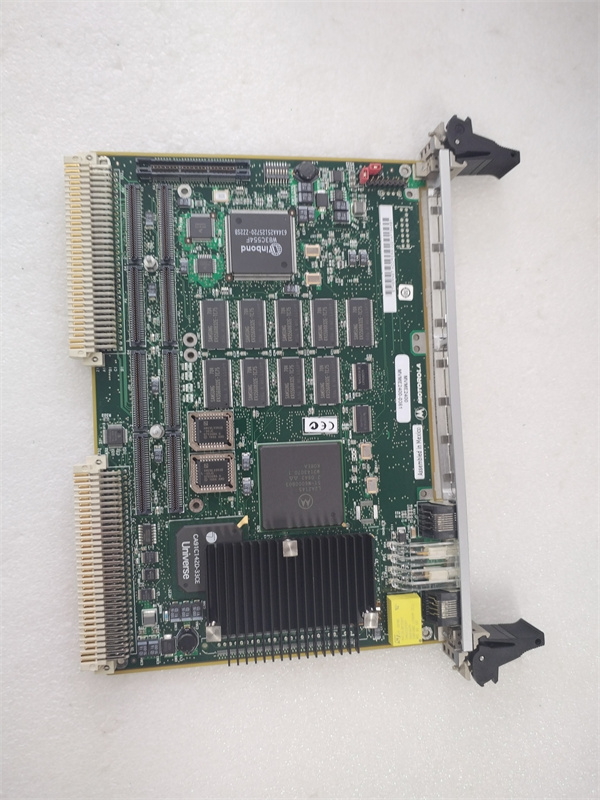

| Product model | Motorola MVME2400 Series |

| Manufacturer | Motorola (Emerson) |

| Product category | VMEbus Embedded Processor Module |

| Microprocessor | PowerPC 750 (233MHz for MVME2401/2402/2432; 350MHz for MVME2431/2433/2434) |

| Memory configuration | 32MB ECC SDRAM (MVME2401); 128MB ECC SDRAM (MVME2431); ECC protection standard |

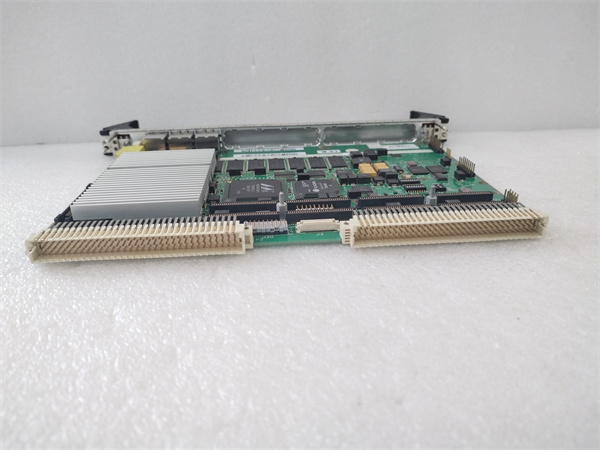

| Expansion capability | 2×PMC slots; PCI bus interface; Universe II VME-to-PCI bridge |

| Physical dimensions | Typical 6U VME form factor (specific dimensions subject to model) |

| Environmental requirements | Temp (operation/non-operation): -40°C to +85°C; Humidity: 0%-95% non-condensing @60°C (with conformal coating: condensing); Altitude: 50,000ft (without lithium battery); Vibration: MIL-STD-810G, DO-160D |

| Emission standards | EN 61326:1997, FCC Class A, EN 55022-A |

| Architecture features | PowerPlus II architecture; Multi-Processor Interrupt Controller (MPIC); Watchdog timers |

Motorola MVME2400

Product Introduction

The **Motorola MVME2400 Series** represents a family of high-performance VMEbus embedded processor modules, engineered to deliver reliable real-time computing capabilities in mission-critical environments. Built around the PowerPC 750 microprocessor architecture, these modules balance computational power with low power consumption, making them ideal for embedded systems requiring both performance and efficiency. As part of Motorola’s VMEbus product lineup, the MVME2400 Series seamlessly integrates into existing VME-based infrastructures, offering flexibility through customizable configurations and advanced I/O capabilities.

Designed for rugged industrial applications, the MVME2400 Series incorporates ECC SDRAM for data integrity, dual PMC slots for expansion, and a Universe II VME-to-PCI bridge for high-speed bus transactions. Its PowerPlus II architecture optimizes peripheral component interconnect (PCI) bus operations, ensuring efficient data transfer between on-board peripherals and external devices. This combination of features positions the MVME2400 Series as a versatile platform for industrial automation, aerospace, defense, and telecommunications applications where reliability and expandability are paramount.

Core Advantages and Technical Highlights

Reliable PowerPC performance: The MVME2400 Series leverages the PowerPC 750 processor’s 233MHz/350MHz clock speeds, delivering consistent computational power for real-time control tasks. The inclusion of ECC SDRAM enhances data reliability by detecting and correcting single-bit errors, critical for applications like avionics and industrial control where data integrity cannot be compromised.

Extreme environmental ruggedness: Certified to operate in temperatures ranging from -40°C to +85°C and withstand 50,000ft altitude, the MVME2400 Series meets MIL-STD-810G and DO-160D vibration standards. With conformal coating options enabling operation in condensing humidity environments, these modules excel in harsh conditions such as aerospace missions, offshore drilling platforms, and industrial manufacturing facilities.

Flexible expansion architecture: Equipped with two PMC slots and a PCI bus interface, the MVME2400 Series supports customization with specialized I/O modules for analog/digital conversion, communication protocols, or graphics processing. The Universe II bridge chip facilitates seamless VME-to-PCI transactions, ensuring compatibility with legacy VME systems while enabling high-speed data transfer to modern peripherals.

Robust system management: Integrated Multi-Processor Interrupt Controller (MPIC) and watchdog timers enhance system stability by managing interrupts and preventing software hangs. The PowerPlus II architecture optimizes bus contention handling and transaction ordering, reducing latency in time-sensitive applications like radar signal processing and robotics control.

Typical Application Scenarios

In aerospace and defense, the MVME2400 Series serves as the processing core for avionics systems, radar signal processing units, and military communication equipment. Its rugged design withstands extreme temperatures, vibration, and electromagnetic interference, while ECC memory ensures mission-critical data integrity. For example, in airborne radar systems, the 350MHz PowerPC 750 variant (MVME2431/2433/2434) accelerates target detection algorithms without compromising reliability.

Within industrial automation, these modules power control and monitoring systems for manufacturing plants, semiconductor fabrication tools, and industrial robots. The dual PMC slots allow integration of specialized I/O cards for sensor data acquisition and actuator control, while real-time processing capabilities ensure sub-millisecond response times for precision manufacturing processes. In telecommunications, the MVME2400 Series manages network switching equipment and base station controllers, leveraging its low power consumption to reduce operational costs in large-scale deployments.

In medical devices and transportation systems, the MVME2400 Series provides stable processing for diagnostic equipment, train signaling systems, and vehicle control units. Its compliance with emission standards (EN 61326, FCC Class A) ensures compatibility with sensitive electronic equipment in healthcare facilities and public transit environments.

Related Model Variants

| Model | Processor Speed | Memory | Key Differentiator |

| MVME2401-1/3 | 233MHz | 32MB ECC SDRAM | Entry-level variant for cost-sensitive applications |

| MVME2431-1/3 | 350MHz | 128MB ECC SDRAM | High-memory option for data-intensive tasks |

| MVME2433-1/3 | 350MHz | Customizable memory | Enhanced I/O for telecommunications applications |

| MVME2402-1/3 | 233MHz | 32MB ECC SDRAM | Dual PMC slots with extended temperature range |

Motorola MVME2400

Installation and Maintenance Guidelines

Installation notes: The MVME2400 Series modules require a 6U VME chassis with appropriate cooling. Convection-cooled units necessitate an external fan to maintain operating temperatures within the -40°C to +85°C range. Ensure proper grounding during installation to prevent electrostatic discharge damage. Align the module’s edge connectors with the chassis backplane and secure with front-panel screws to ensure stable bus connections.

Maintenance recommendations: Periodically inspect the module for dust accumulation and verify cooling airflow. Monitor ECC memory error logs to detect potential hardware issues early. For conformal-coated variants, avoid harsh cleaning agents that may damage the coating. Firmware updates and technical support are available through Motorola’s official support portal (visit en-us.support.motorola.com and select the specific MVME2400 model).

Service and Support Information

Motorola provides comprehensive technical support for the MVME2400 Series through its global service network. Customers can access product documentation, firmware updates, and troubleshooting resources via the official support website. For hardware repairs and replacement, contact Motorola’s authorized service partners or submit a service request through the support portal. Extended service contracts are available for mission-critical applications, offering priority support and accelerated repair turnaround times.

As part of Emerson’s industrial computing portfolio, the MVME2400 Series benefits from ongoing lifecycle support, ensuring compatibility with legacy systems and providing upgrade paths to newer VMEbus or PCIe-based platforms as application requirements evolve.