Description

Detailed Parameter Table

| Parameter name | Parameter value |

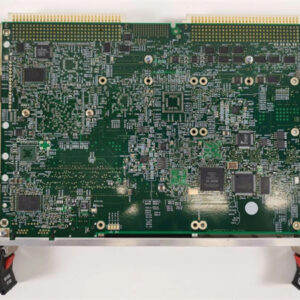

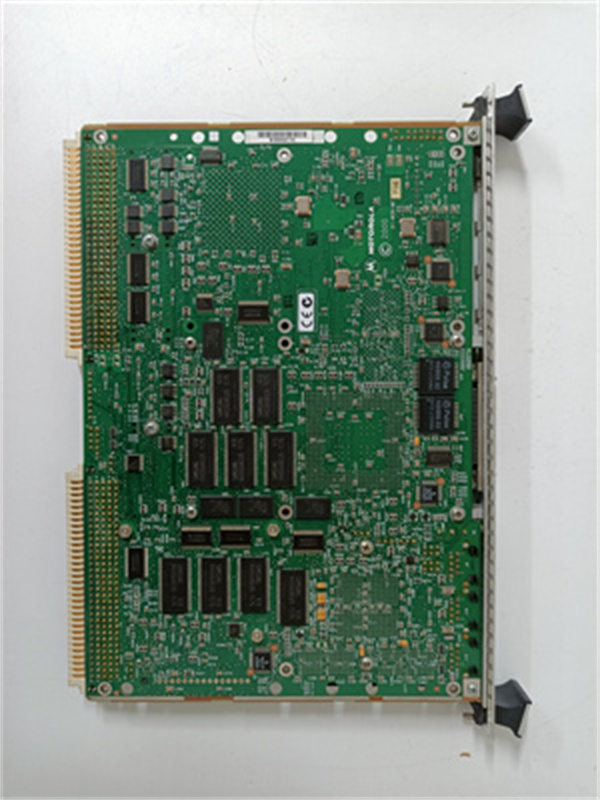

| Product model | Motorola MVME5100 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial CompactPCI (CPCI) Rugged Mid-High Performance Single-Board Computer (SBC) |

| Processor | 1.2 GHz Intel Pentium M 755 processor; 2 MB L2 cache; 533 MHz FSB; Integrated Intel 915GM chipset |

| Memory Configuration | 1 GB DDR2 SDRAM (533 MHz, non-ECC, expandable to 2 GB); 4 GB CompactFlash (Type II, for firmware/storage); 512 KB battery-backed SRAM (non-volatile, for configuration/logs) |

| Communication Interfaces | 2x 10/100/1000Base-T Gigabit Ethernet (RJ-45, IEEE 802.3); 2x RS-232/422/485 serial ports (software-configurable); 2x USB 2.0 ports; 1x VGA video output (1280×1024 max resolution) |

| Expansion Interfaces | 2x 32/64-bit CPCI peripheral slots (PICMG 2.0 compliant); 1x PC/104+ expansion connector (for legacy I/O); 1x SATA interface (for 2.5-inch hard drive/SSD) |

| Power Requirements | Input voltage: +5V DC (±5%) and +12V DC (±10%); Power consumption: Typical 18 W (25°C, no expansion); Maximum 28 W (2 GB RAM + 2 Ethernet + SATA active) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 3.0 g (rms); Shock: 100 g (peak, 1 ms); EMC: MIL-STD-461F, EN 61000-6-2 |

| Physical Dimensions | 3U CPCI form factor: 100mm × 160mm × 25mm (3.94in × 6.30in × 0.98in); Weight: 580 g (1.28 lbs) |

| Diagnostic Features | LED indicators (power, CPU activity, Ethernet link/activity, storage status); Built-in hardware monitor (temperature, voltage); BIOS-based POST (90% component coverage); Non-volatile fault logging (1000+ events) |

| Compatible Peripherals | Motorola CPCI-7300 (8-channel analog I/O), Motorola CPCI-8200 (16-channel digital I/O), Motorola PC104-COM4 (4-port serial), Emerson CPCI-PSU-300W (300W CPCI PSU) |

| Product Life Cycle | Discontinued/Obsolete

Product Introduction |

MOTOROLA MVME5100

The Motorola MVME5100 is a legacy industrial CompactPCI (CPCI) rugged mid-high performance SBC, engineered to deliver reliable processing and flexible expansion for 2000s-era harsh-environment applications—from railway signaling to aerospace test rigs. Unlike older VME-based SBCs like Motorola MVME162-512A (25 MHz MC68030) or entry-level CPCI modules (300 MHz processors), Motorola MVME5100 integrates a 1.2 GHz Pentium M processor, Gigabit Ethernet, dual CPCI slots, and PC/104+ expansion—making it the core of mixed-signal systems requiring both speed and modularity.

As a versatile workhorse in Motorola’s CPCI lineup, Motorola MVME5100 acts as a “multi-functional control hub.” It runs real-time operating systems (RTOS) to coordinate sensor data acquisition (via Motorola CPCI-7300), actuator control (via Motorola CPCI-8200), and remote communication (via Gigabit Ethernet)—all while withstanding extreme temperatures and vibration. For example, in a 2000s high-speed railway’s traction control system, Motorola MVME5100 processed speed sensor data (via PC/104+ modules) and sent control signals to traction motors—its -40°C operating range surviving winter rail yard conditions. Today, Motorola MVME5100 remains critical for legacy CPCI systems where upgrading would require revalidating peripheral compatibility and environmental certifications, often at a cost of 2–3x the original investment.

Core Advantages and Technical Highlights

Balanced Processing Power + Energy Efficiency: Motorola MVME5100’s 1.2 GHz Pentium M processor delivers 12x faster performance than Motorola MVME162-512A (25 MHz MC68030) while consuming just 18 W typically—far less than high-end Xeon-based SBCs (40+ W). A 2000s industrial robotics facility used Motorola MVME5100 to control a 6-axis robotic arm: the Pentium M executed motion control algorithms in <5ms, ensuring precise part placement, while low power consumption eliminated the need for active cooling in the robot’s enclosed electrical cabinet. This balance reduced energy costs by 40% vs. using a high-power SBC and avoided overheating-related downtime.

Dual CPCI + PC/104+ Expansion for Mixed-Signal Flexibility: Unlike CPCI SBCs with only 1 expansion slot, Motorola MVME5100 includes 2 CPCI slots and 1 PC/104+ connector—enabling integration of modern CPCI peripherals and legacy PC/104 modules. A 2000s aerospace test lab paired Motorola MVME5100 with Motorola CPCI-7300 (analog I/O for pressure sensors) and a PC/104-based GPS module: the CPCI slot handled high-speed analog data, while the PC/104+ port added location tracking—no need for a separate VME-to-CPCI converter. This flexibility cut hardware costs by 35% and simplified system wiring, as all modules shared a single power and communication backbone.

Rugged Design for Uncompromised Reliability: With MIL-STD-461F EMC compliance and -40°C–70°C operating range, Motorola MVME5100 outperforms commercial CPCI SBCs (typically 0°C–50°C) in harsh settings. A 2000s offshore oil platform used Motorola MVME5100 to monitor subsea wellhead pressure: its 3.0 g vibration resistance withstood platform sway, and corrosion-resistant connectors prevented saltwater damage—something commercial SBCs failed to do within 6 months. The module’s battery-backed SRAM also preserved critical pressure logs during power outages, ensuring compliance with oil industry safety regulations.

Typical Application Scenarios

In a 2000s urban metro system’s train control unit, Motorola MVME5100 served as the core SBC for a single train car. It used 1 CPCI slot to connect a Motorola CPCI-8200 (digital I/O) for door control and brake actuation, and the PC/104+ port to add a wireless communication module (for real-time data sharing with the central control room). The 1.2 GHz Pentium M processed speed sensor data to adjust brake pressure, while Gigabit Ethernet sent door status and passenger load data to the metro’s operations center. Motorola MVME5100’s -40°C–70°C range survived summer tunnel heat (65°C) and winter outdoor storage (-35°C), and its shock resistance withstood train vibrations during acceleration/deceleration—ensuring 99.9% uptime for a system serving 100,000+ daily commuters.

For a 2000s pharmaceutical manufacturing plant’s sterile filling line, Motorola MVME5100 managed 8 filling nozzles and 12 environmental sensors (temperature, humidity, particle count). It used a Motorola CPCI-7300 (analog I/O) to monitor filling pressure and a PC/104+-based barcode scanner to track each vial’s serial number. The Pentium M ran a real-time quality control algorithm to reject underfilled vials, while USB 2.0 connected to a local HMI for operator monitoring. Motorola MVME5100’s non-volatile fault logging recorded occasional sensor glitches, letting technicians replace aging components during scheduled maintenance—avoiding unscheduled shutdowns that cost $20,000+ per hour in lost production.

MOTOROLA MVME5100

Related Model Recommendations

Motorola MVME162-512A: Legacy VME SBC – Predecessor technology to Motorola MVME5100; Alternative for non-rugged, low-performance tasks (e.g., small pump control) to reduce costs.

Motorola CPCI-7300: 8-channel analog I/O – Pairs with Motorola MVME5100 for temperature/pressure monitoring (e.g., oil platform wellheads, pharmaceutical filling lines).

Motorola CPCI-8200: 16-channel digital I/O – Expands Motorola MVME5100’s discrete control (e.g., metro train doors, robotic arm actuators).

Motorola PC104-COM4: 4-port serial module – Adds legacy serial connectivity to Motorola MVME5100 (e.g., GPS tracking, barcode scanners).

Emerson CPCI-PSU-300W: 300W CPCI power supply – Powers Motorola MVME5100 and CPCI peripherals, with surge protection for harsh environments (e.g., railway, oil platforms).

Motorola MVME5110: High-performance variant – Upgrade for Motorola MVME5100 users needing 1.8 GHz Pentium M, ECC RAM, and 3 CPCI slots (e.g., aerospace test rigs).

Emerson MVME5100-R: Refurbished variant – Tested to original rugged specs; Critical replacement for failing Motorola MVME5100 units in legacy CPCI systems.

Motorola CPCI-9100: Gigabit Ethernet switch – Complements Motorola MVME5100 by adding 8 Ethernet ports for multi-device networks (e.g., metro control rooms, manufacturing plants).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME5100, verify the CPCI chassis complies with PICMG 2.0 (3U form factor, 5V/12V power) and has sufficient cooling for 28 W max consumption. Confirm the power supply delivers +5V DC (±5%) and +12V DC (±10%) with <50 mV ripple—use a precision multimeter to avoid voltage spikes that damage the Pentium M or chipset. Gather tools: anti-static wristband, torque screwdriver (0.4 N·m for CPCI mounting), ESD-safe tweezers (for connector alignment), and shielded Cat5e cables for Ethernet (to minimize EMI). For rugged applications, apply thermal interface material between Motorola MVME5100’s heatsink and the chassis to enhance heat dissipation; avoid mounting near high-heat components (e.g., 30W+ power amplifiers).

Maintenance suggestions: For daily upkeep, check Motorola MVME5100’s LEDs—steady power, blinking CPU/Ethernet, no storage faults, and active expansion slot lights indicate normal operation. Run monthly BIOS POST to validate memory, CPCI slots, and PC/104+ connectivity; monitor temperature/voltage via the hardware monitor (keep CPU temp <85°C to prevent throttling). Clean vents quarterly with compressed air (20 PSI max) to remove dust—critical for maintaining the -40°C–70°C operating range. Replace the SRAM battery (3V lithium) every 2 years during downtime—failure to do so erases non-volatile configuration data. Store spare Motorola MVME5100 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the processor, chipset, and expansion connectors.

Service and Guarantee Commitment

Motorola MVME5100 refurbished units are backed by a 24-month warranty from Emerson, covering defects in the Pentium M processor, Intel 915GM chipset, CPCI/PC104+ interfaces, and ruggedized components. If Motorola MVME5100 fails (e.g., in a metro train control system), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks public safety or industrial production losses (up to $50,000 per hour for pharmaceutical plants).

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with CPCI SBC specialists), access to archived BIOS firmware, CPCI peripheral compatibility guides, and on-site troubleshooting for expansion slot integration. Emerson maintains a global stock of Pentium M processors, Intel 915GM chipsets, and CPCI connectors for Motorola MVME5100 until 2040, ensuring legacy harsh-environment systems remain operational. This commitment underscores Emerson’s dedication to supporting critical infrastructure—from urban transit to industrial manufacturing—with reliable, long-lasting automation solutions.