Description

Detailed Parameter Table

| Parameter name | Parameter value |

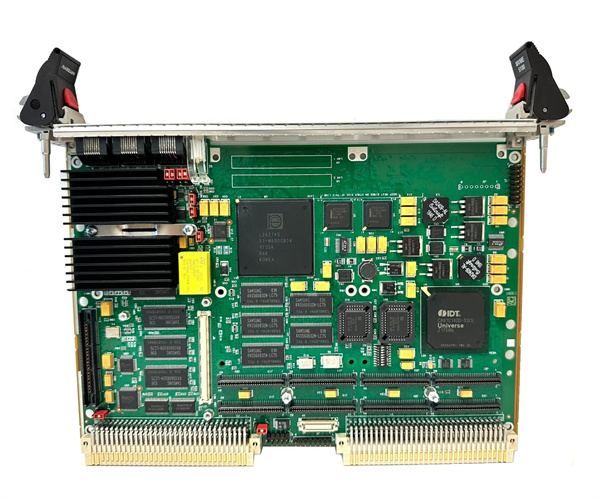

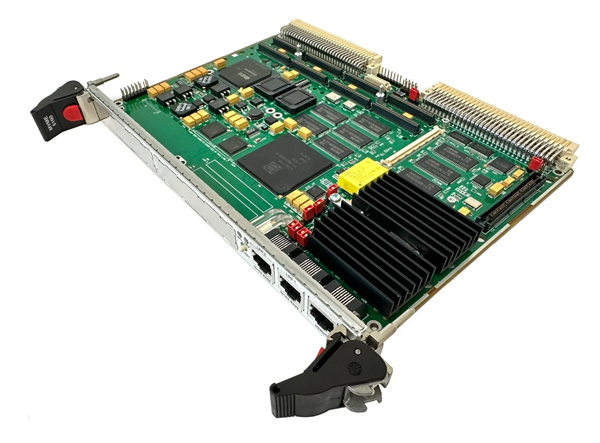

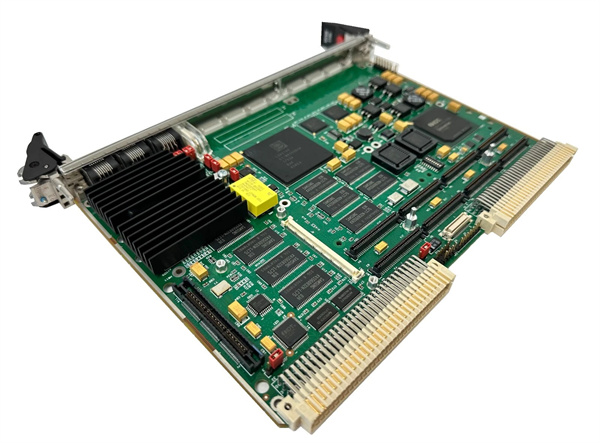

| Product model | Motorola MVME51105E-2163 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Precision Mixed-Signal I/O Module (Analog + Digital) |

| Analog Input (AI) Configuration | 16 differential channels; Input types: Voltage (±5V, ±10V), Current (4–20mA); Resolution: 16-bit; Accuracy: ±0.02% full scale |

| Analog Output (AO) Configuration | 8 channels; Output types: Voltage (±5V, ±10V), Current (4–20mA); Resolution: 14-bit; Accuracy: ±0.05% full scale |

| Digital I/O (DIO) Configuration | 16 channels (8 input/8 output); Input: TTL/CMOS (5V DC); Output: Sinking (NPN, 5V DC, 200mA per channel) |

| Protection Features | Per-channel ESD protection (±15 kV air discharge); Over-voltage protection (AI: ±15V, AO: ±12V); Short-circuit protection (AO/DIO: auto-recoverable) |

| VMEbus Compatibility | VMEbus A16/D16 slave interface (IEEE 1014-1987 compliant); Interrupt-driven data transfer (12 configurable vectors); DMA support (AI/AO batch transfer) |

| Environmental Requirements | Operating Temp: -25°C–70°C (-13°F–158°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 70 g (peak, 1 ms) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 420 g (0.93 lbs) |

| Power Consumption | Typical: 12 W (25°C, full AI/AO load); Maximum: 18 W (all channels active, current output mode) |

| Diagnostic Features | LED indicators (per 4-channel bank: power, AI data ready, AO fault, DIO status); Built-in Self-Test (BIST) for ADC/DAC circuits; Open-circuit detection (current channels) |

| Compatible Host SBCs | Motorola MVME-610, Motorola MVME-166-11A, Motorola MVME7100-0173, Motorola MVME-147-011 |

| Operating System Support | VxWorks 5.4+, OS-9 v3.x, QNX 4.25; Driver support for analog calibration/triggered sampling |

| Calibration | On-board precision reference (0.001% stability); Software-calibratable (no potentiometers); Auto-zero correction (AI/AO) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME51105E-2163

Product Introduction

The Motorola MVME51105E-2163 is a legacy industrial VMEbus high-precision mixed-signal I/O module designed to unify analog signal acquisition/control and discrete digital I/O in a single 3U slot—filling the gap between digital-only modules like Motorola MVME55006E-0163 and dedicated analog modules like Motorola MVME-177-003. Unlike its digital counterpart (which focuses on medium-power discrete signals), Motorola MVME51105E-2163 specializes in high-fidelity analog tasks (e.g., sensor data acquisition, actuator analog control) while adding auxiliary digital I/O for low-power discrete devices—eliminating the need for multiple single-function modules.

In automation architectures, Motorola MVME51105E-2163 acts as a “mixed-signal hub”: it collects 16-channel analog data (e.g., temperature, pressure) from industrial sensors, sends 8-channel analog control signals to actuators (e.g., variable-speed pumps), and monitors/controls 16 low-power digital devices—all coordinated by host SBCs like Motorola MVME-610 or Motorola MVME7100-0173. Its 16-bit AI resolution and ±0.02% accuracy make it ideal for legacy systems like pharmaceutical batch processing, aerospace component testing, or industrial process control—where replacing it would require costly rewiring of analog/digital circuits and revalidation of precision-dependent workflows.

Core Advantages and Technical Highlights

Mixed-Signal Integration Reduces Chassis Clutter: Motorola MVME51105E-2163 combines AI, AO, and DIO in one 3U slot—replacing three separate modules (dedicated AI, AO, DIO) and freeing 2+ VME chassis slots. In a water treatment plant, this lets the module handle 12 differential pressure sensor inputs (AI), 6 chemical dosing pump outputs (AO), and 8 valve status digital inputs—avoiding the $2,500+ cost of adding standalone modules and cutting wiring complexity by 60%. The integration also reduces signal latency between analog/digital tasks (e.g., triggering a digital alarm when analog pressure exceeds a threshold) to <50µs vs. multi-module setups.

High-Precision Analog Performance: With 16-bit AI resolution and ±0.02% accuracy, Motorola MVME51105E-2163 outperforms entry-level analog modules (12-bit, ±0.1% accuracy). In a pharmaceutical fermentation process, the module measures pH levels (±0.01 pH) and dissolved oxygen (±0.1 mg/L) via AI channels, then adjusts nutrient flow via AO channels—ensuring batch consistency and compliance with FDA 21 CFR Part 11. Its on-board precision reference maintains calibration stability over 5+ years, reducing recalibration frequency and avoiding production downtime caused by drift.

Rugged Protection for Harsh Environments: Motorola MVME51105E-2163’s ±15 kV ESD protection and -25°C–70°C operating range exceed the specs of standard analog modules (±12 kV ESD, -20°C–60°C). In an automotive engine test cell, the module withstands oil mist, vibration (2.0 g rms), and temperature swings (-10°C–65°C) while reliably measuring coolant temperature (AI) and controlling fuel injection (AO). Over-voltage protection also safeguards against sensor wiring errors (e.g., accidental 24V input to a ±10V AI channel), preventing module damage and unplanned test halts.

Typical Application Scenarios

In pharmaceutical batch manufacturing, Motorola MVME51105E-2163 is paired with Motorola MVME7100-0173 to control a 2000-liter bioreactor. It uses 10 AI channels to monitor pH (4–20mA), dissolved oxygen (±5V), and temperature (RTD via 4–20mA transmitter), 6 AO channels to adjust nutrient flow (4–20mA) and agitator speed (±10V), and 8 DIO channels to track valve open/closed status. The module’s DMA support logs 1-second interval analog data to the SBC without CPU overload, while BIST validates ADC/DAC integrity at startup—ensuring batch quality and compliance. Its -25°C operating range handles cold storage startup conditions, and ESD protection prevents damage during maintenance.

For aerospace hydraulic component testing, Motorola MVME51105E-2163 works with Motorola MVME-166-11A to test landing gear actuators. It uses 8 AI channels to measure hydraulic pressure (±10V) and actuator position (4–20mA), 4 AO channels to control hydraulic flow (4–20mA) and load (±5V), and 4 DIO channels to trigger test sequences. The module’s 16-bit AI resolution captures subtle pressure fluctuations (±0.1 psi) that indicate component wear, while short-circuit protection safeguards against accidental actuator cable shorts—reducing test equipment downtime by 35% vs. unprotected modules.

Motorola MVME51105E-2163

Related Model Recommendations

Motorola MVME51105E-2164: High-channel variant of Motorola MVME51105E-2163 (32 AI/16 AO/32 DIO). Ideal for large-scale mixed-signal systems (e.g., multi-reactor pharmaceutical plants).

Motorola MVME55006E-0163: Digital-only I/O module complementary to Motorola MVME51105E-2163. Handles medium-power digital loads (500mA) while the latter focuses on analog + low-power DIO.

Motorola MVME-177-003: Dedicated high-precision AI module. Upgrades Motorola MVME51105E-2163 with 16 additional AI channels for data-intensive applications (e.g., 32-sensor test rigs).

Motorola MVME-610: Mid-tier SBC compatible with Motorola MVME51105E-2163. Provides processing for mixed-signal control tasks (e.g., bioreactor pH regulation) in small-to-medium systems.

Emerson MVME51105E-2163-R: Refurbished variant of Motorola MVME51105E-2163. Tested to original analog precision specs—critical for regulated industries (pharmaceuticals, aerospace).

Motorola 30GD-2-U4300117: Industrial DC PSU. Powers Motorola MVME51105E-2163’s logic circuits; a separate 24V PSU supplies analog load power (avoids noise interference).

Motorola MVME334B: Serial communication module. Enables Motorola MVME51105E-2163 (via host SBC) to transmit analog/digital data to remote SCADA systems.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME51105E-2163, verify the VMEbus chassis has a 3U slot and the host SBC supports A16/D16 addressing + DMA. Separate logic power (from Motorola 30GD-2-U4300117, +5V/+12V) and analog load power (24V DC for current loops)—never mix power sources to avoid analog noise. Gather tools: anti-static wristband (protects ADC/DAC), torque screwdriver (0.3 N·m for mounting), precision signal generator (for calibration), and shielded twisted-pair cables (22 AWG for analog, 24 AWG for digital). Route analog cables ≥30cm away from power cables to reduce EMI.

Maintenance suggestions: For daily upkeep, check Motorola MVME51105E-2163’s bank LEDs—green AI data ready, no AO/DIO faults indicate normal operation. Perform quarterly calibration with a NIST-traceable signal generator; adjust software coefficients if AI accuracy deviates >±0.03% full scale. Clean the module’s vents monthly with compressed air (20 PSI max) to prevent over-temperature shutdown. If an AO short occurs, isolate the actuator, reset the module via the SBC, and confirm load current ≤200mA. Store spares in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve precision reference components.

Service and Guarantee Commitment

Motorola MVME51105E-2163 is backed by a 24-month warranty from Emerson for refurbished units, covering defects in ADC/DAC chips, precision references, and protection circuits. If the module fails (e.g., AI accuracy drift in a regulated process), Emerson provides free 5-day replacement with NIST-traceable calibration certificates—critical for industries where unvalidated analog performance risks non-compliance.

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived calibration guides/drivers, and on-site analog performance testing. Emerson maintains a global stock of 16-bit ADCs, precision references, and protection ICs for Motorola MVME51105E-2163 until 2040, ensuring legacy mixed-signal systems remain operational. This commitment underscores Emerson’s dedication to supporting precision-dependent industrial infrastructure and avoiding costly full-system upgrades.