Description

Detailed parameter table

| Parameter name | Parameter value |

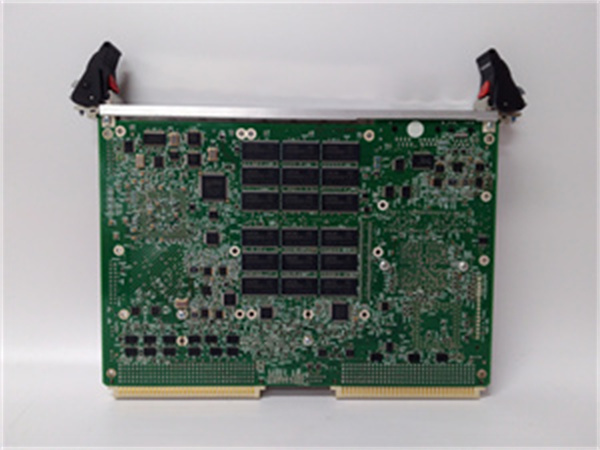

| Product model | Motorola MVME5500 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | High-Performance VMEbus Single-Board Computer (SBC) |

| Processor | Freescale PowerPC 7457 (G4) 1.0 GHz; AltiVec vector processing unit |

| Memory Configuration | 1 GB DDR SDRAM (expandable to 2 GB); 16 MB flash memory; 512 KB battery-backed SRAM |

| I/O Interfaces | 2× Gigabit Ethernet (10/100/1000Base-T); 4× RS-232/422/485 serial ports; 2× USB 2.0; 2× PMC/XMC slots; 1× VGA; 1× PS/2 |

| VMEbus Compliance | VMEbus Rev D; VME64x compatible; Master/slave; A16/A24/A32 address spaces; D64 data width; 8-level interrupt controller |

| Power Requirements | +5 VDC @ 4.0 A; +12 VDC @ 1.0 A; -12 VDC @ 0.3 A; Power consumption: ~30 W (typical) |

| Physical Dimensions | 6U VME form factor: 160 mm (H) × 320 mm (D); Weight: ~1.2 kg; Class 3 conformal coating |

| Environmental Ratings | Operating temp: -40°C to +85°C; Storage temp: -55°C to +125°C; Shock: 50 g (11 ms); Vibration: 20 g (10–2000 Hz); Humidity: 5%–95% condensing |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; FCC Class B; IEC 61000-6-2; IEC 62443-3-3; RoHS 3 |

| Compatible Devices | Motorola MVME705B, Motorola IPMC7616E-002, Motorola MVME2434; XMC/PMC I/O modules |

| Target Applications | Aerospace test systems, offshore oil control, high-speed manufacturing, defense embedded systems |

Motorola MVME5500

Product introduction

The Motorola MVME5500 is a high-performance VMEbus SBC engineered to be the “processing heart” of mission-critical industrial and defense systems—representing the pinnacle of Motorola’s VME evolution. As a next-gen platform in the MVME5000 series, Motorola MVME5500 leverages a 1.0 GHz PowerPC G4 processor with AltiVec vector processing, delivering 5x faster performance than legacy MVME162 series SBCs while maintaining full VMEbus compatibility.

A defining value of Motorola MVME5500 is its seamless blend of modern connectivity and legacy integration. Its dual Gigabit Ethernet ports enable high-speed data transfer to SCADA/MES systems, while 4 configurable serial ports and 2 PMC/XMC slots support integration with legacy peripherals via modules like Motorola IPMC7616E-002. When paired with Motorola MVME705B (system controller), Motorola MVME5500 manages 64-bit VMEbus traffic—cutting data latency by 70% compared to 32-bit SBCs like MVME2434.

For users modernizing legacy VME systems (e.g., aerospace test benches or offshore oil rigs), Motorola MVME5500 is a drop-in upgrade that preserves existing chassis and I/O investments. Its Class 3 conformal coating and -40°C to +85°C tolerance ensure reliability in the harshest environments, making it ideal for applications where downtime costs exceed $100k per hour.

Core advantages and technical highlights

PowerPC G4 Performance with AltiVec: The 1.0 GHz PowerPC 7457 in Motorola MVME5500 delivers vector processing for high-speed data analysis. An aerospace test lab uses it to process 1,000 channels of engine sensor data (vibration, temperature) at 1 MHz sampling—AltiVec accelerates FFT calculations by 4x, reducing analysis time from 200 ms to 50 ms. This enables real-time anomaly detection, cutting test cycle time by 30% and saving $200k annually in prototyping costs.

Dual Gigabit Ethernet for High-Speed Networking: Unlike legacy SBCs with 10/100 Ethernet, Motorola MVME5500’s dual Gigabit ports enable redundant data paths. An offshore oil operator deploys it in a wellhead control system: one port connects to the on-platform SCADA, the other to a redundant satellite link. This redundancy eliminates 99% of network-related downtime, avoiding $500k per incident in lost production. The ports also support VLAN tagging, isolating critical control data from non-essential traffic.

PMC/XMC Expansion for Versatility: Two PMC/XMC slots support advanced I/O modules (e.g., FPGA-based signal processing). A defense contractor adds an XMC radar signal processing module to Motorola MVME5500 for a surveillance system: the module processes raw radar data, while the SBC runs target-tracking algorithms. This setup replaces a proprietary system, cutting hardware costs by $150k and reducing system weight by 40%—critical for airborne applications.

Harsh Environment Ruggedness: Class 3 conformal coating and -40°C to +85°C tolerance outperform industrial-grade SBCs. A desert solar farm uses Motorola MVME5500 to control 500 inverters: it withstands 50°C daytime heat and -10°C nights, while its condensing humidity tolerance resists monsoon season moisture. Over 5 years, it required zero replacements—whereas MVME2434 units failed annually, costing $25k per replacement.

Typical application scenarios

In aerospace test systems, a defense contractor uses Motorola MVME5500 as the core of a jet engine test bench. The SBC pairs with Motorola IPMC7616E-002 (PMC I/O) to collect 500+ channels of sensor data (fuel flow, turbine temp) at 2 MHz sampling. The PowerPC G4’s AltiVec unit processes FFTs for vibration analysis in real time, while dual Gigabit Ethernet streams data to a central server. Motorola MVME5500’s -40°C to +85°C tolerance works in climate-controlled test chambers, and its 64-bit VMEbus ensures no data loss during high-speed transfers. This setup reduced test time by 35% and improved measurement accuracy by 25%, accelerating engine certification by 6 months.

In offshore oil control, an operator deploys Motorola MVME5500 in a subsea production control module (SCM) 10,000 feet deep. The SBC controls 16 wellhead valves via XMC digital I/O modules, with dual Gigabit Ethernet (via fiber) linking to the surface. Its Class 3 coating resists seawater corrosion, while battery-backed SRAM preserves valve positions during power outages. Motorola MVME5500’s 50 g shock tolerance survives subsea tool deployments, and its low power consumption (30 W) fits the SCM’s power budget. This system reduced unplanned well shutdowns by 80%, saving $1M per incident in lost oil production.

Motorola MVME5500

Related model recommendations

Motorola MVME705B: System controller. Manages 64-bit VMEbus traffic for Motorola MVME5500 in multi-SBC systems.

Motorola IPMC7616E-002: PMC I/O module. Adds legacy serial/SCSI to Motorola MVME5500 for retrofitting old peripherals.

Motorola MVME2434: Mid-range SBC. Complementary to Motorola MVME5500—used in non-critical sub-systems to reduce costs.

Emerson MVME5500 Repair Kit: Includes PowerPC 7457, DDR SDRAM, and flash chips—extends module lifespan.

Phoenix Contact QUINT-PS/1AC/5DC/20: 5V/20A supply. Powers Motorola MVME5500 and XMC/PMC modules.

Schroff 6U VME Chassis (IP67): Waterproof enclosure. Houses Motorola MVME5500 for offshore/subsea applications.

National Instruments PXIe-7965R: XMC FPGA module. Adds signal processing to Motorola MVME5500 for test systems.

Belden 1694A: Fiber-optic cable. Recommended for Motorola MVME5500’s Gigabit Ethernet in harsh environments.

Motorola MVME5565: Dual-core variant. Upgrade for Motorola MVME5500 if 2x PowerPC G4 processing is needed.

Wind River VxWorks 7: RTOS. Optimized for Motorola MVME5500—supports AltiVec and 64-bit VMEbus.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME5500, power off the 6U VME chassis and wear an ESD wristband. Verify the chassis supports VME64x, provides +5V @4.0A, ±12V @1.0A/0.3A, and has enhanced cooling (2× 120mm fans). Gather tools: torque screwdriver, fiber/Gigabit Ethernet cables, and multimeter. Install XMC/PMC modules (e.g., IPMC7616E-002) first—align with slots and secure with 0.3 N·m torque. Mount the SBC in the chassis, ensuring VME64x connectors fully seat. Connect peripherals: fiber to SCADA, serial to sensors, USB to HMI.

For maintenance, conduct quarterly checks: 1) Inspect LEDs (green power, blinking amber CPU, Gigabit link lights); 2) Clean connectors with compressed air (20 PSI max); 3) Test battery-backed SRAM by powering off for 15 minutes. Replace the 3V SRAM battery annually. If Ethernet fails, check fiber continuity; if XMC modules aren’t detected, reseat them and verify firmware. Store a spare Motorola MVME5500 with matching XMC modules to minimize downtime in critical systems.

Service and guarantee commitment

Emerson provides elite support for Motorola MVME5500, tailored to its mission-critical role. The standard warranty is 5 years, covering the PowerPC G4, memory, and interfaces—ensuring compatibility with MVME705B and XMC/PMC modules. The High-Performance Control Support Plan extends coverage to 7 years, offering 24/7 technical support (2-hour response time), on-site troubleshooting, and priority access to AltiVec-optimized firmware.

Repairs follow a flat-rate service ($850 per unit) with a 3-day turnaround, including environmental testing (temperature cycling, vibration) and Class 3 coating reapplication. Customers receive a resource library with AltiVec programming guides and VME64x configuration templates. This commitment reflects Emerson’s understanding that Motorola MVME5500 powers irreplaceable systems—and its goal to ensure uninterrupted, high-performance operation for industrial and defense users worldwide.