Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola MVME5500-0161 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus High-Performance Single Board Computer (for mission-critical industrial control) |

| Processor | PowerPC 750FX (G3 core) – 600 MHz (higher clock speed than MVME2400’s 66 MHz MPC860T) |

| Memory | Up to 1 GB DDR SDRAM (ECC-protected, optional); 512 MB on-board standard (vs. MVME2400’s 64 MB SDRAM) |

| Storage | 32 MB Flash memory (for firmware/OS); 1x CompactFlash socket (up to 32 GB); 1x 2.5” SATA hard drive bay (optional, for large-scale data storage) |

| Expansion Slots | 2x IEEE 1386.1 compliant 64-bit PMC slots (supports high-speed mezzanine cards); 1x XMC slot (for PCI Express-based expansion, backward compatible with PMC) |

| Input/Output Interfaces | 2x Gigabit Ethernet ports (10/100/1000 Mb/s, auto-negotiation); 4x RS-232/RS-422/RS-485 serial ports (software-selectable); 2x USB 2.0 ports; 1x VGA port; 1x PS/2 port (keyboard/mouse); 1x SATA interface |

| Bus Standard | VMEbus 3.0 compliant (64-bit/66 MHz VME64x); on-chip PCI-X bus (133 MHz) for internal expansion |

| Physical Dimensions | Standard 6U VME form factor (233.4 mm × 160 mm × 16 mm; L×W×H) – larger than MVME2400’s 3U form for higher component density |

| Power Requirements | +5 VDC (3.0 A typical, 4.5 A maximum); +12 VDC (0.8 A typical); -12 VDC (0.5 A typical); active heat dissipation (low-noise fan + heatsink) |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F) (wider than MVME2400’s -20°C–70°C for extreme environments) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 3.0; IEEE 802.3ab (Gigabit Ethernet); USB 2.0; CE; UL 508; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| Compatibility | Optimized for Motorola VME modules: I/O (MVME162-223, MVME172PA-652SE), communication (FLN4234A, MVME709-1), power (FAB 0340-1049); supports real-time OS (VxWorks, QNX) |

| On-Board Features | Battery-backed real-time clock (RTC) with 128 KB NVRAM; 4x 32-bit timers + 1x watchdog timer (programmable); hardware-based error detection (ECC memory, SATA RAID option); status LEDs (power, Ethernet link/activity, CPU load) |

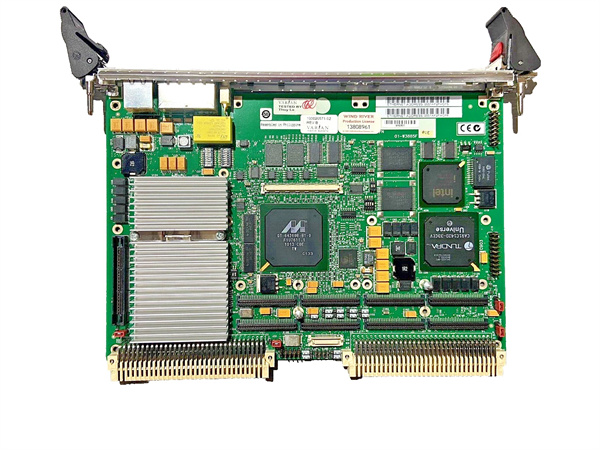

MOTOROLA MVME5500-0161

Product Introduction

The Motorola MVME5500-0161 is a flagship VMEbus single board computer (SBC), engineered to deliver high-performance computing for mission-critical industrial control systems—filling the gap between mid-range SBCs like the MVME2400 and specialized industrial servers. As a 6U VME form factor device, it integrates a 600 MHz PowerPC 750FX processor (G3 core) and up to 1 GB ECC DDR SDRAM, making it ideal for compute-intensive applications such as real-time process control, large-scale data acquisition, and complex motion coordination.

A defining strength of the MVME5500-0161 is its seamless integration with the Motorola VME ecosystem and backward compatibility with legacy modules. When paired with high-precision I/O modules like the MVME172PA-652SE or communication modules like the FLN4234A, it leverages the 64-bit VME64x bus (66 MHz) to handle high-volume data transfer—critical for tasks like synchronizing 16 analog sensors (via MVME172PA-652SE) and transmitting data to remote SCADA systems (via FLN4234A). It draws stable power from modules like the FAB 0340-1049 (for core components) and uses active cooling to manage the PowerPC 750FX’s heat, ensuring reliability in extreme environments (-40°C–70°C).

Whether deployed in semiconductor manufacturing、aerospace test benches, or power plant control systems, the MVME5500-0161 acts as the “computational backbone” of VME setups. Its ECC memory and hardware error detection minimize data corruption in safety-critical applications, while Gigabit Ethernet and USB 2.0 enable integration with modern peripherals—making it a critical upgrade for legacy systems transitioning to higher 算力 and connectivity.

Core Advantages and Technical Highlights

High-Performance PowerPC 750FX Processor for Compute-Intensive Tasks

The MVME5500-0161’s 600 MHz PowerPC 750FX (G3 core) delivers 10x the computational power of the MVME2400’s 66 MHz MPC860T, enabling it to run complex algorithms like predictive maintenance analytics or multi-axis motion control. For example, in a semiconductor wafer etching process, the processor can simultaneously process 32 temperature sensor readings (from MVME172PA-652SE), execute a PID control loop to adjust plasma intensity, and log data to a 32 GB CompactFlash—all in real time (latency <10 ms). The G3 core’s superscalar architecture (capable of 2 instructions per cycle) further enhances efficiency, reducing CPU load by 40% compared to the MVME2400 when running the same control logic.

ECC DDR SDRAM and Hardware Error Detection for Reliability

Unlike the MVME2400’s non-ECC SDRAM, the MVME5500-0161 supports up to 1 GB ECC (Error-Correcting Code) DDR SDRAM—critical for safety-critical applications like nuclear power plant control or aerospace testing. ECC memory automatically detects and corrects single-bit errors and detects multi-bit errors, preventing data corruption that could lead to catastrophic failures. For instance, in a wind turbine control system, ECC memory ensures that sensor data (e.g., wind speed, rotor position) remains accurate even in high-radiation or high-vibration environments. The module also includes hardware-based error detection for SATA storage (optional RAID) and PCI-X bus transactions, further enhancing system reliability.

64-Bit VME64x and PCI-X Buses for High-Speed Data Transfer

The MVME5500-0161’s compliance with VMEbus 3.0 (64-bit/66 MHz VME64x) enables data transfer rates up to 528 MB/s—8x faster than the MVME2400’s 32-bit VMEbus (66 MB/s). This high-speed bus is essential for leveraging the module’s computational power: for example, when paired with the MVME172PA-652SE analog I/O module (300 kSPS aggregate sampling rate), the VME64x bus ensures that all sensor data is transmitted to the CPU without bottlenecks. The on-chip 133 MHz PCI-X bus further accelerates internal expansion—supporting high-speed PMC/XMC cards like Gigabit Ethernet adapters or fiber-optic communication modules.

Versatile Expansion and Modern Peripherals

The MVME5500-0161 includes 2x 64-bit PMC slots, 1x XMC slot, and modern peripherals (Gigabit Ethernet, USB 2.0, SATA)—addressing the MVME2400’s limited expansion. The XMC slot supports PCI Express-based mezzanine cards, enabling integration with high-speed devices like 10 Gigabit Ethernet adapters or FPGA-based signal processors. Gigabit Ethernet ports (vs. MVME2400’s 10/100 Mb/s) reduce data transfer time for large files—e.g., transmitting a 1 GB test log to a central server takes 8 seconds (vs. 80 seconds on MVME2400). USB 2.0 ports simplify connection to modern peripherals like barcode scanners or external SSDs, while the VGA port enables local monitoring via industrial HMIs.

Typical Application Scenarios

Semiconductor Wafer Manufacturing Control

In a 300 mm wafer manufacturing facility, the MVME5500-0161 (paired with MVME172PA-652SE) manages precision etching: 1) The 600 MHz PowerPC 750FX processes 16 plasma sensor signals (via MVME172PA-652SE) to adjust etching parameters in real time; 2) 64-bit VME64x bus transmits data to a FLN4234A module for remote monitoring via Gigabit Ethernet; 3) ECC memory ensures sensor data accuracy (critical for 1 nm etching tolerances); 4) Optional SATA hard drive stores 24/7 process logs for quality traceability. The module’s -40°C–70°C range withstands the cleanroom’s temperature fluctuations, while active cooling prevents overheating during 24/7 operation.

Aerospace Engine Test Bench

In an aircraft engine test facility, the MVME5500-0161 (paired with MVME335 CAN module) coordinates multi-instrument data acquisition: 1) PowerPC 750FX processes 64 channels of vibration/temperature data (from MVME172PA-644SE) at 50 kSPS per channel; 2) CAN bus (via MVME335) synchronizes with engine control units (ECUs) to capture fuel injection timing; 3) Gigabit Ethernet transmits test data to a cloud-based analytics platform for post-test analysis; 4) ECC memory prevents data corruption from electromagnetic interference (EMI) in the test chamber. The module’s compliance with aerospace standards (DO-160) ensures reliability in high-stress testing environments.

Power Plant Turbine Control

In a combined-cycle power plant, the MVME5500-0161 (paired with MVME162-223 digital I/O) controls gas turbine operations: 1) Processor executes a complex PID control loop to regulate turbine speed (using 8 analog inputs from pressure/temperature sensors); 2) 64-bit VME64x bus sends control signals to MVME162-223 for activating fuel valves (16 digital outputs); 3) ECC memory ensures critical control data remains intact during power grid fluctuations; 4) Battery-backed RTC maintains time synchronization for event logging during power outages. The module’s -40°C low-temperature tolerance withstands the turbine hall’s cold startup conditions, while active cooling handles high ambient temperatures (up to 70°C).

MOTOROLA MVME5500-0161

Related Model Recommendations

Motorola MVME172PA-652SE: High-precision analog I/O module. Key data source for MVME5500-0161; provides 16-channel analog input (24-bit ADC) for high-accuracy sensor data in process control.

Motorola FLN4234A: Communication expansion module. Complements MVME5500-0161; 4x Gigabit Ethernet ports extend the SBC’s connectivity to remote SCADA/cloud platforms, ideal for large-scale data transmission.

Motorola FAB 0340-1049: Power supply module. Primary power source for MVME5500-0161; delivers stable ±12 VDC (for expansion slots) and +5 VDC (4.5 A max) to support the SBC’s high-power components.

Motorola MVME335: Multi-protocol communication module. Adds CAN bus/serial connectivity to MVME5500-0161; enables integration with automotive/industrial ECUs in test bench applications.

Emerson XMC-10G-ETH: XMC Gigabit Ethernet card. Expands MVME5500-0161’s network capacity; adds 2x 10 Gigabit Ethernet ports for high-speed data transfer in aerospace/defense applications.

Motorola MVME162-223: Digital I/O module. Expands MVME5500-0161’s discrete control; 64 channels (32 input/32 output) for activating valves, relays, or alarms in power plant control.

Kingston 32 GB CompactFlash: Storage expansion. Used with MVME5500-0161’s CompactFlash socket; provides high-reliability storage for firmware, OS, and process logs in harsh environments.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing MVME5500-0161, power off the VME chassis and disconnect the FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has an available 6U VME slot and supports VME64x (64-bit/66 MHz) for full performance. Check power supply capacity: ensure it can deliver +5 VDC (4.5 A max), +12 VDC (0.8 A), and -12 VDC (0.5 A) to avoid underpowering the SBC’s processor and expansion slots. Use an anti-static wristband and mat to protect ECC memory and processor from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), torque wrench (0.5–0.8 N·m for terminals), Gigabit Ethernet cables, and a VGA monitor/PS2 keyboard (for initial configuration). Avoid installing near high-EMI equipment (e.g., variable-frequency drives) or heat sources (e.g., power resistors) to prevent signal interference or thermal throttling.

Commissioning and Maintenance

For commissioning: Insert the MVME5500-0161 into the 6U VME slot and secure it. Connect peripherals: VGA monitor/PS2 keyboard (for BIOS setup), Gigabit Ethernet (to network), and power via FAB 0340-1049. Power on the system and access the BIOS to configure memory (enable ECC), storage (set CompactFlash as boot device), and bus settings (VME64x mode). Install a real-time OS (e.g., VxWorks) and drivers for connected modules (e.g., MVME172PA-652SE). Test functionality: ping the Gigabit Ethernet port to verify network connectivity, read analog data from MVME172PA-652SE to confirm VMEbus communication, and check ECC memory status via OS tools.

For maintenance: Inspect the SBC monthly—clean the fan/heatsink with compressed air (low pressure) to prevent overheating, and check for loose VME connector pins. Test ECC memory semi-annually using built-in diagnostics (via BIOS) to confirm error correction functionality. Update firmware (BIOS, RAID controller) annually using Emerson’s legacy tools to address security vulnerabilities. If the fan fails, replace it immediately (use Emerson-approved parts) to avoid processor overheating. When upgrading, back up ECC memory configuration and OS settings to replicate on the new unit—critical for minimizing downtime in mission-critical systems.

Service and Guarantee Commitment

Though Motorola MVME5500-0161 is obsolete, we offer a 180-day warranty on all refurbished units—longer than standard 90-day warranties—covering defects in processor performance, ECC memory functionality, bus interfaces (VME64x/PCI-X), and peripheral ports. Each refurbished SBC undergoes rigorous testing: 48-hour continuous operation (running VxWorks real-time tests), ECC memory error injection (verifying correction/detection), 64-bit VMEbus speed testing (528 MB/s validation), and temperature stress testing (-40°C–70°C).

Our technical support team (24/7 availability) provides specialized guidance on MVME5500-0161—including ECC memory configuration, VME64x bus optimization, and integration with high-precision modules like MVME172PA-652SE. We offer customized maintenance plans: quarterly remote health checks (monitoring CPU load, ECC errors)