Description

Detailed Parameter Table

| Parameter name | Parameter value |

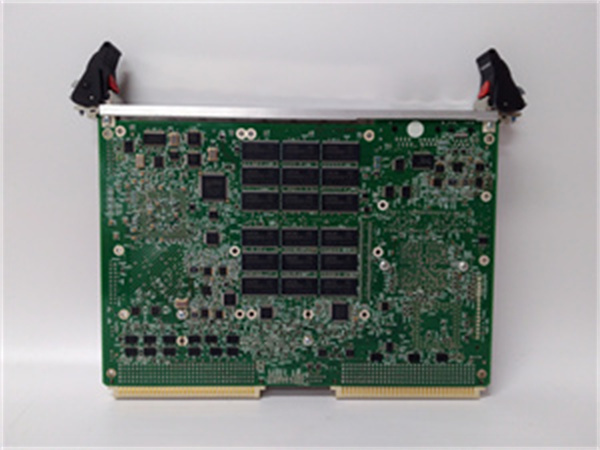

| Product model | Motorola MVME55006E-0163 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Density Digital I/O Module |

| I/O Configuration | 64 digital channels (32 input/32 output); Input type: TTL/CMOS (5V DC, 0–0.8V LOW/2.0–5.5V HIGH); Output type: Sourcing (PNP, 5V DC, 500mA per channel) |

| Protection Features | Per-channel short-circuit protection (3A trip, auto-recoverable); Over-temperature protection (70°C shutdown, auto-reset); Channel-to-channel isolation (250V AC rms) |

| VMEbus Compatibility | VMEbus A16/D16 slave interface (IEEE 1014-1987 compliant); Interrupt-driven I/O (8 configurable vectors); Polled mode support |

| Environmental Requirements | Operating Temp: -20°C–70°C (-4°F–158°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.8 g (rms); Shock: 60 g (peak, 1 ms) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 380 g (0.84 lbs) |

| Power Consumption | Typical: 9 W (25°C, full load); Maximum: 15 W (all channels active, 500mA output) |

| Diagnostic Features | LED indicators (per 8-channel bank: power, input status, output status, fault); Built-in Self-Test (BIST) for I/O circuits; Open-circuit detection (output channels) |

| Compatible Host SBCs | Motorola MVME-610, Motorola MVME-166-11A, Motorola MVME7100-0173, Motorola MVME-147-011 |

| Operating System Support | VxWorks 5.4+, OS-9 v3.x, QNX 4.25; Driver support for legacy VME system software |

| Mounting Options | Standard 3U VMEbus chassis mounting; Optional DIN-rail adapter (accessory part number: MVME-DIN-001) |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME55006E-0163

Product Introduction

The Motorola MVME55006E-0163 is a legacy industrial VMEbus high-density digital I/O module designed to expand discrete signal handling capabilities for mid-tier control systems—filling the gap between low-current I/O modules and high-power modules like Motorola MVME2101-1. Unlike computing modules such as Motorola MVME-610 (focused on processing), Motorola MVME55006E-0163 specializes in translating digital control signals from host SBCs into actionable power for medium-load actuators (e.g., relays, small solenoids) while monitoring sensor inputs.

In automation architectures, Motorola MVME55006E-0163 acts as a “discrete signal hub”: it connects 32 digital sensors (e.g., limit switches, photoelectric detectors) and 32 medium-power actuators to host SBCs like Motorola MVME-610 via the VMEbus. For example, in a packaging line, Motorola MVME55006E-0163 monitors “package present” sensors (inputs) and activates sealing solenoids (outputs) based on commands from Motorola MVME-610. Its 500mA per-channel output capacity and channel isolation make it ideal for legacy systems like automotive sub-assembly lines, material handling equipment, or industrial oven control—where replacing it would require costly rewiring of dozens of discrete devices and revalidation of safety workflows.

Core Advantages and Technical Highlights

High-Density + Medium-Power Output: Motorola MVME55006E-0163 packs 64 channels (32 DI/32 DO) in a 3U slot, with 500mA per-channel sourcing output—double the capacity of low-current modules (200mA max). In an automotive component plant, this lets the module directly power 32 relay coils (24V DC, 300mA each) for robotic grippers, eliminating the need for external relay panels that add $1,200+ in costs and 50% more wiring time. The high density also reduces VME chassis slot usage by 50% vs. 32-channel modules, freeing space for other components like Motorola MVME334B (serial communication).

Robust Protection for Industrial Reliability: With per-channel short-circuit protection and 250V AC channel isolation, Motorola MVME55006E-0163 safeguards both the module and connected devices. In a food processing plant, if a cleaning crew accidentally damages a solenoid cable connected to Motorola MVME55006E-0163, the module’s short-circuit protection trips within 100µs—preventing damage to the host SBC (e.g., Motorola MVME-610) and avoiding a 4-hour production outage. Over-temperature protection also ensures reliability in hot environments (e.g., near industrial ovens), extending the module’s lifespan to 8+ years vs. 3–5 years for unprotected alternatives.

Seamless Legacy SBC Compatibility: Motorola MVME55006E-0163 works natively with SBCs across Motorola’s legacy lineup, from entry-level Motorola MVME-147-011 to mid-tier Motorola MVME-610 and high-performance Motorola MVME7100-0173. A manufacturing plant upgrading from Motorola MVME-147-011 to Motorola MVME7100-0173 can reuse existing Motorola MVME55006E-0163 modules—avoiding $8,000+ in replacement costs. Its driver support for legacy OS (e.g., VxWorks 5.4) also eliminates the need for software rewrites, reducing upgrade time by 60%.

Typical Application Scenarios

In automotive door panel assembly, Motorola MVME55006E-0163 is paired with Motorola MVME-610 to control a 10-station assembly cell. It uses 24 input channels to monitor “part seated” sensors (TTL 5V) and 16 output channels to activate riveting tools (500mA, 24V DC). The module’s interrupt-driven I/O alerts Motorola MVME-610 within 1ms if a sensor fails, halting the line to prevent misaligned rivets—reducing defect rates by 30% and saving $5,000+ weekly in rework. Its -20°C–70°C operating range withstands the plant’s seasonal temperature fluctuations, while vibration resistance handles nearby robotic arm movements.

For warehouse conveyor control, Motorola MVME55006E-0163 manages 32 conveyor sections with Motorola MVME7100-0173 as the host SBC. Input channels track photoeye sensors (detecting packages), and output channels activate conveyor motors (500mA, 12V DC) and divertor solenoids. The module’s BIST runs automatically on startup, verifying all channels are functional—critical for 24/7 warehouse operations where unplanned downtime costs $2,000+ per hour. Channel isolation also prevents electrical noise from adjacent conveyors from corrupting sensor data, ensuring 99.99% uptime.

Motorola MVME55006E-0163

Related Model Recommendations

Motorola MVME55006E-0164: High-current variant of Motorola MVME55006E-0163 (1A per output channel). Ideal for power-hungry actuators (e.g., 1A DC motors) in heavy-duty manufacturing.

Motorola MVME-610: Mid-tier SBC compatible with Motorola MVME55006E-0163. Provides processing to send/receive I/O signals, forming a complete discrete control system for small-to-medium applications.

Motorola MVME2101-1: Ultra-high-current DO module (2A per channel). Complements Motorola MVME55006E-0163 by handling large loads (e.g., 2A contactors) while the latter manages medium-power devices.

Motorola MVME334B: Serial communication module. Enables Motorola MVME55006E-0163 (via host SBC) to transmit I/O status data to remote HMIs or SCADA systems.

Emerson MVME55006E-0163-R: Refurbished variant of Motorola MVME55006E-0163. Tested to original I/O/protection specs—cost-effective replacement for failing units in legacy systems.

Motorola 30GD-2-U4300117: Industrial DC PSU. Powers Motorola MVME55006E-0163’s logic circuits, while a separate 24V PSU supplies output load power (avoids overloading logic power).

Motorola MVME-177-003: Analog input module. Adds high-precision analog data (e.g., temperature) to Motorola MVME55006E-0163’s discrete control system for mixed-signal applications.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME55006E-0163, verify the VMEbus chassis has a 3U slot and the host SBC (e.g., Motorola MVME-610) supports A16/D16 addressing. Separate logic power (from Motorola 30GD-2-U4300117, +5V DC) and load power (24V DC PSU for outputs)—never connect load power to logic terminals. Gather tools: anti-static wristband (protects I/O circuits), torque screwdriver (0.3 N·m for mounting), digital multimeter (check polarity), and wire crimpers (for 18AWG load cables). Use twisted-pair cables for I/O wiring; route load cables 20cm away from signal cables to reduce EMI.

Maintenance suggestions: For daily upkeep, check Motorola MVME55006E-0163’s bank LEDs—green for active inputs/outputs, red for faults. Test 10% of channels weekly via the host SBC (activate output, verify status readback) to detect latent issues. Clean the module’s vents monthly with compressed air (25 PSI max) to prevent over-temperature shutdown. If a short-circuit fault occurs, isolate the load (check cable continuity), reset the module via the SBC, and confirm load current ≤500mA. Store spare Motorola MVME55006E-0163 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve protection circuit components.

Service and Guarantee Commitment

Motorola MVME55006E-0163 is backed by an 18-month warranty from Emerson for refurbished units, covering defects in I/O drivers, protection circuits, and isolation components. If the module fails (e.g., output channel failure in a critical assembly line), Emerson provides free 7-day replacement—critical for systems where I/O downtime halts production.

For extended support, customers can purchase a 36-month service contract, including 24/7 remote troubleshooting (via phone/email), access to archived drivers (e.g., VxWorks 5.4 compatible), and on-site I/O testing. Emerson maintains a global stock of I/O transistors and protection ICs for Motorola MVME55006E-0163 until 2038, ensuring legacy discrete control systems remain operational. This commitment underscores Emerson’s dedication to supporting mid-tier industrial infrastructure and avoiding costly full-system upgrades.