Description

Product Overview

**

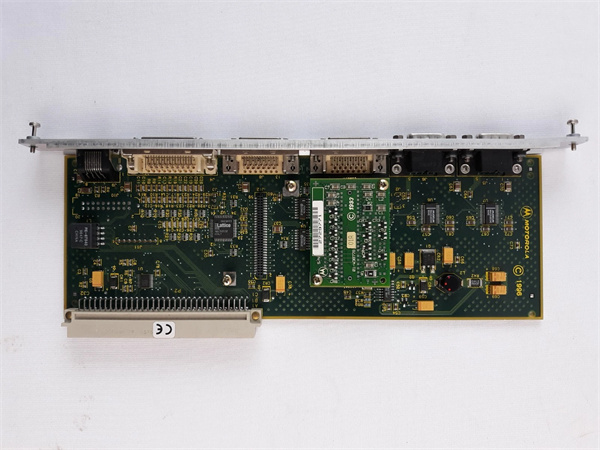

The Motorola MVME712 – 101 is a communication module within the MVME712 series, tailored for industrial control and data transfer in VMEbus – based systems. As part of Motorola’s product line now under Emerson, it continues to be a reliable choice for industries needing seamless communication interfaces. It shares a similar design philosophy with the MVME712 – 103 but may have some distinct features and applications.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME712 – 101 |

| Manufacturer | Motorola (now under Emerson) |

| Product category | Communication Module (VMEbus – compatible) |

| Serial Ports | [Number] of multi – protocol serial ports (e.g., could be EIA – 232 – D or other standards). These ports can be configured as DTE or DCE, enabling connection to a wide array of serial – based devices such as sensors, actuators, and legacy communication gear. |

| Other Interfaces | Features an Ethernet port for high – speed network connectivity, facilitating data transfer to and from upper – level systems or for remote monitoring and control. There may also be additional interfaces like a SCSI – like port for connecting to storage or other compatible peripherals, and potentially a printer port or other specialized ports depending on the design. |

| Weight | Ship weight is approximately [X] lbs per unit, which is designed to be lightweight enough for easy installation in various industrial chassis. |

| Compatibility | Compatible with a range of Motorola VMEbus single – board computers, likely including models like the MVME147, MVME1600, MVME162, etc. This broad compatibility allows for seamless integration into existing industrial control architectures. |

| Power Requirements | Operates within a specific power range. The exact voltage and current requirements may vary based on the application and the peripherals connected. It typically draws power from the VMEbus backplane, ensuring a stable power source for reliable operation. |

Motorola MVME-761-001

Product Introduction

The MVME712 – 101 acts as a crucial bridge between the processor module and peripheral devices in VMEbus – based systems. It simplifies external customer cable requirements by providing rear – panel industry – standard connectors. The P2 adapter assembly (similar to related modules) routes I/O signals and grounds from the P2 connector on the chassis backplane, at the VME module MPU connection, to the MVME712 – 101. The module then distributes these signals to its serial ports, which are implemented as industry – standard connectors on its front panel.

In industrial settings, the MVME712 – 101 functions as a communication hub. For example, in a manufacturing plant, it can connect a VME – based controller to multiple serial – connected sensors that monitor temperature, pressure, and position. The Ethernet port can be used to transmit the aggregated data from these sensors to a central control room for real – time monitoring and analysis. The additional interfaces, such as a potential SCSI – like port, can be utilized to connect to a local storage device, enabling data logging and retrieval, which is essential for quality control and process optimization.

Core Advantages and Technical Highlights

Flexible Serial Connectivity: The MVME712 – 101 offers flexibility in serial communication. With its multi – protocol serial ports that can be configured as DTE or DCE, it can interface with a wide variety of devices. In an industrial environment where legacy equipment often uses serial communication protocols, this feature is extremely useful. For instance, in a textile factory, it can connect to older – generation looms and knitting machines that rely on serial communication for control and data transfer.

High – Speed Ethernet Connectivity: The inclusion of an Ethernet port enables high – speed data transfer, which is vital for modern industrial applications that demand real – time data exchange. In a smart factory setup, the MVME712 – 101 can use the Ethernet port to communicate with other network – connected devices, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and enterprise – level servers. This allows for seamless integration of production data into the overall enterprise network.

Industry – Standard Connectors: By providing industry – standard connectors on its front panel, the MVME712 – 101 simplifies the cabling process. This reduces the complexity of system integration and maintenance. In an automotive manufacturing facility, technicians can easily connect and disconnect peripheral devices without the need for specialized cabling or adapters, minimizing downtime during equipment upgrades or repairs.

Compatibility with Multiple VMEbus SBCs: Its compatibility with a wide range of Motorola VMEbus single – board computers ensures that it can be integrated into existing systems with ease. In a power generation plant, if the existing control system uses an MVME162 SBC, the MVME712 – 101 can be added to expand the communication capabilities without the need for a complete system overhaul.

Typical Application Scenarios

Industrial Automation: In a large – scale manufacturing plant, the MVME712 – 101 can be used to connect various industrial devices. It can interface with PLCs, which control the production line operations, and transmit data to HMIs for operator monitoring. For example, in a food processing plant, the module can connect to multiple servo – controlled motors (communicating via serial ports) and use the Ethernet port to send real – time production data to a central management system.

Data Logging and Monitoring: In a wastewater treatment facility, the MVME712 – 101 can be used to collect data from multiple sensors (such as pH sensors, flow meters, and dissolved oxygen sensors) connected via its serial ports. The data can then be stored on a storage device connected through its specialized interface (like a SCSI – like port) for long – term analysis. The Ethernet port can be used to send summary data to a remote monitoring station, allowing for remote management of the treatment process.

Test and Measurement: In an electronics testing laboratory, the MVME712 – 101 can be used to control and communicate with test equipment. For example, it can connect to oscilloscopes, signal generators, and power supplies via serial ports. The Ethernet port can be used to transfer test results to a computer for further analysis and report generation.

Motorola MVME-761-001

Related Model Recommendations

Motorola MVME712/M: This related I/O transition module can be used in tandem with the MVME712 – 101 in complex systems. While the MVME712 – 101 focuses on communication, the MVME712/M has a broader I/O transition functionality. In a large – scale industrial control system, the MVME712/M can handle general I/O transitions, and the MVME712 – 101 can be dedicated to communication tasks.

Motorola MVME162: A high – performance VMEbus single – board computer that pairs well with the MVME712 – 101. The MVME162 can efficiently process the data received and sent by the MVME712 – 101. In an aerospace component testing facility, the MVME162 can use the data from the MVME712 – 101 (connected to various test sensors) to perform complex calculations and control the testing process.

Motorola MVME050: An industrial power supply module that can provide the necessary power for the MVME712 – 101 and other components in the VMEbus system. In a harsh industrial environment, such as a mining site, the MVME050 can ensure a stable power supply to the MVME712 – 101, enabling reliable communication and operation.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the MVME712 – 101, ensure that the VMEbus chassis is compatible and provides stable power. Check the jumper settings on the module according to the desired serial port configurations (DTE or DCE). Gather the necessary tools, such as an anti – static wristband to protect the sensitive electronic components, a screwdriver for mounting the module in the chassis, and appropriate cables for connecting to peripheral devices.

Commissioning: After installation, power on the system. Use diagnostic software (compatible with the VMEbus system) to check the functionality of the MVME712 – 101. Verify that the serial ports, Ethernet port, and other interfaces are working correctly. Test the communication with connected devices by sending and receiving sample data.

Maintenance Suggestions: Regularly check the status of the module. Inspect the LEDs on the front panel (if available) to ensure normal operation. For the serial ports, periodically clean the connectors to prevent oxidation and ensure good electrical contact. If there are any communication issues, first check the cables and connections. If the problem persists, use diagnostic tools to identify whether it is a module – related issue or a problem with the connected device. Store spare MVME712 – 101 modules in a static – free environment to maintain their integrity.

Service and Guarantee Commitment

The Motorola MVME712 – 101 typically comes with a standard warranty, usually around 12 months (terms may vary depending on the region and reseller). This warranty covers defects in materials and workmanship. In case of a malfunction within the warranty period, Emerson (or authorized resellers) will provide repair or replacement services. For extended support, additional service contracts can be purchased, which may include priority technical support, longer – term warranties, and regular system health checks.