Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | Motorola MVME715P |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Rugged High-Density Digital I/O Expansion Module |

| Digital Input Channels | 32 isolated digital input channels; TTL/24V DC compatible; Input current: 5mA@24V DC; Response time: <10μs |

| Digital Output Channels | 32 isolated digital output channels; Open-collector (sink) configuration; Max sink current: 500mA per channel (2A per 8-channel bank); Overcurrent protection (self-resetting polyfuses) |

| Isolation & Protection | Channel-to-channel galvanic isolation (2500V AC rms); Power isolation (1500V AC rms); Reverse polarity protection (inputs/outputs); ESD protection (±15kV contact, ±25kV air) |

| Communication Interface | 32-bit VMEbus slave (IEEE 1014-1987, A16/D16); Interrupt-driven data transfer (configurable interrupt levels 1–7); DMA support for high-speed I/O (up to 1MHz transfer rate) |

| Diagnostic Features | LED indicators (power, VMEbus status, input activity, output fault, overcurrent); Channel-level fault detection (open circuit, short circuit); Power-on self-test (POST, 90% component coverage); Non-volatile fault logging (1000+ events) |

| Power Requirements | Input voltage: +5V DC (±5%), +24V DC (±10%); Power consumption: Typical 8 W (25°C); Maximum 15 W (all channels active, max load) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 3.0 g (rms); Shock: 100 g (peak, 1 ms); EMC: MIL-STD-461F, EN 61000-6-2 |

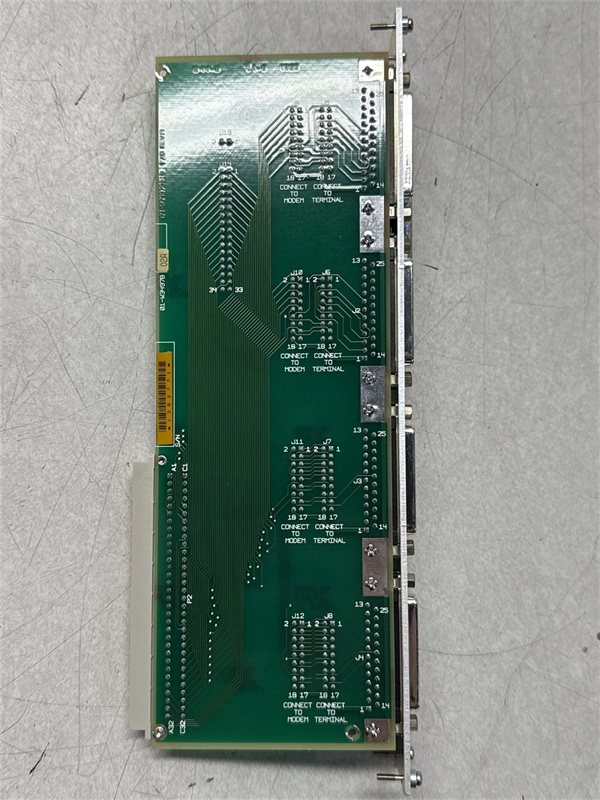

| Physical Dimensions | 3U VME form factor: 100mm × 160mm × 26mm (3.94in × 6.30in × 1.02in); Weight: 480 g (1.06 lbs) |

| Compatible SBCs | Motorola MVME705B, Motorola MVME710B, Motorola MVME187, Motorola MVME2604, Motorola MVME162-512A |

| Expansion Compatibility | Supports daisy-chaining (up to 4 modules) for 128 input/output channels; Compatible with Motorola MVME712A/AM (analog I/O) for mixed-signal systems |

| Product Life Cycle | Discontinued/Obsolete |

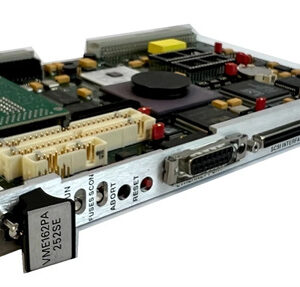

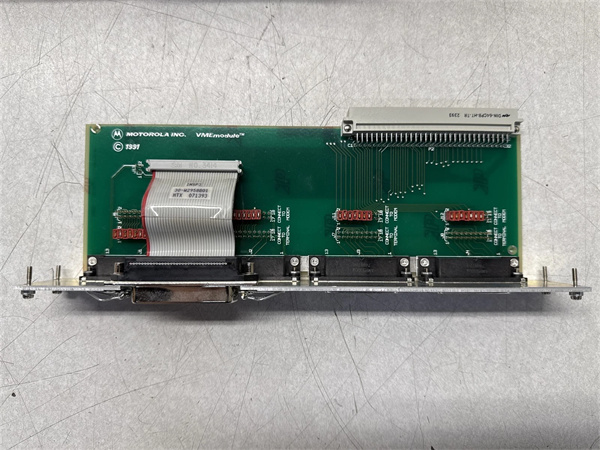

MOTOROLA MVME715P

Product Introduction

The Motorola MVME715P is a legacy industrial VMEbus rugged high-density digital I/O expansion module, engineered to extend the discrete control capabilities of high-performance SBCs like Motorola MVME705B—targeting 2000s-era applications demanding high channel counts and reliability in harsh environments. Unlike low-density digital modules (e.g., Motorola MVME147-013 with 32 total I/O channels), Motorola MVME715P delivers 64 dedicated digital channels (32 input/32 output), robust isolation, and overcurrent protection—making it ideal for tasks like military vehicle actuator control, industrial assembly line discrete monitoring, or power grid switchgear management.

As a specialized digital hub in Motorola’s rugged VME lineup, Motorola MVME715P acts as a “discrete signal manager.” It converts digital sensor signals (e.g., limit switches, proximity sensors) into data for SBC processing and translates SBC commands into high-current outputs to control actuators (e.g., relays, valves). For example, in a 2000s military armored vehicle, Motorola MVME715P paired with Motorola MVME705B to monitor 24 door/hatches (via digital inputs) and control 16 weapon system actuators (via digital outputs)—its 2500V AC isolation protecting against electrical noise from the vehicle’s engine. Today, Motorola MVME715P remains vital for legacy rugged systems where upgrading would require reconfiguring hundreds of discrete wiring connections and validating military/aerospace compliance.

Core Advantages and Technical Highlights

High-Density I/O + Daisy-Chaining for Scalability: Motorola MVME715P’s 64 digital channels (32 input/32 output) and daisy-chaining support (up to 4 modules) eliminate the need for multiple low-density modules. A 2000s automotive assembly plant used Motorola MVME715P with Motorola MVME705B to control a 4-station assembly line: 1 module monitored 32 proximity sensors (part presence) and controlled 32 conveyor motors—reducing VME chassis slot usage by 75% vs. using 4x Motorola MVME147-013 modules. Daisy-chaining later let the plant add a second Motorola MVME715P to expand to 8 stations without reengineering the bus architecture.

High-Current Outputs + Overcurrent Protection for Actuator Control: Unlike most digital modules (100mA max per channel), Motorola MVME715P’s outputs sink up to 500mA per channel (2A per bank)—ideal for high-power actuators. A 2000s power utility used Motorola MVME715P to control 16 high-voltage switchgear relays: the 500mA outputs directly drove the relays (no external amplifiers needed), while self-resetting polyfuses prevented damage from shorted relay coils. This integration reduced component count by 40% and eliminated 8 hours of weekly maintenance (from failed amplifiers).

Rugged Isolation + EMC Compliance for Harsh Environments: With 2500V AC isolation and MIL-STD-461F compliance, Motorola MVME715P outperforms commercial digital modules in noisy or high-voltage settings. A 2000s offshore wind farm used Motorola MVME715P to monitor 32 turbine blade position sensors and control 32 brake actuators: isolation prevented ground loops from offshore electrical systems corrupting data, while EMC compliance withstood lightning-induced EMI. Commercial modules failed within 3 months in this environment, while Motorola MVME715P operated reliably for 7+ years.

Typical Application Scenarios

In a 2000s military unmanned ground vehicle (UGV) control system, Motorola MVME715P served as the primary digital I/O module for Motorola MVME705B. It used 32 digital inputs to monitor obstacle sensors, wheel encoders, and battery status, and 32 digital outputs to control drive motors, steering actuators, and defensive systems (e.g., smoke generators). Motorola MVME715P’s 100 g shock resistance survived rough terrain impacts, while its -40°C–70°C range withstood desert and arctic deployment conditions. The module’s overcurrent protection also prevented damage when a drive motor shorted, letting the UGV return to base under reduced power.

For a 2000s beverage bottling plant’s filling line, Motorola MVME715P paired with Motorola MVME705B to automate 32 filling nozzles. It used 32 digital inputs to detect bottle presence (via photoeyes) and cap alignment (via limit switches), and 32 digital outputs to activate filling valves, capping motors, and reject conveyors. The module’s 500mA outputs directly drove the filling valves (no external relays), while interrupt-driven data transfer ensured <10μs response time to bottle jams—reducing product waste by 25%. Motorola MVME715P’s fault logging also recorded occasional valve short circuits, letting technicians replace aging valves during off-peak hours.

MOTOROLA MVME715P

Related Model Recommendations

Motorola MVME705B: High-performance SBC – Primary pairing for Motorola MVME715P; Processes digital data from the module for rugged applications (e.g., military UGV control).

Motorola MVME712A/AM: Analog I/O module – Complements Motorola MVME715P; Adds analog channels for mixed-signal systems (e.g., beverage plant temperature/pressure monitoring).

Motorola MVME715B: High-current variant – Upgrade for Motorola MVME715P users needing 1A per output channel (e.g., heavy-industry motor control).

Motorola MVME2307: Serial expansion module – Pairs with Motorola MVME715P; Adds serial ports for remote HMI connectivity (e.g., wind farm turbine control).

Emerson MVME715P-R: Refurbished variant – Tested to original isolation/current specs; Critical replacement for failing Motorola MVME715P units in legacy systems.

Emerson 24V DC Industrial PSU: Rugged power supply – Powers Motorola MVME715P and paired SBCs; Provides stable +24V for high-current outputs (e.g., military vehicles).

Motorola MVME147-013: Low-density digital I/O – Alternative for Motorola MVME715P users with <32 I/O needs (e.g., small-scale HVAC) to reduce costs.

Motorola MVME710B: High-performance SBC – Alternative pairing for Motorola MVME715P; Handles higher data volumes (e.g., large-scale power grid switchgear).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME715P, verify the VME chassis supports 3U modules and provides +24V DC (±10%) for high-current outputs (in addition to +5V). Confirm compatibility with the paired SBC (e.g., Motorola MVME705B) via VMEbus A16/D16 addressing. Gather tools: anti-static wristband, torque screwdriver (0.4 N·m for 3U mounting), multimeter (to test input voltages), and 18 AWG wire for output channels (handles 500mA current). For daisy-chaining, use shielded VMEbus cables (max length 1m) to avoid signal degradation; label input/output channels clearly to prevent wiring errors.

Maintenance suggestions: For daily upkeep, check Motorola MVME715P’s LEDs—steady power, no fault/overcurrent lights, and active input/output indicators mean normal operation. Run monthly POST to validate isolation and channel functionality; review fault logs quarterly to identify trends (e.g., recurring overcurrent on specific output banks). Clean vents every 3 months with compressed air (20 PSI max) to prevent dust buildup. If an output channel fails, replace the self-resetting polyfuse (1A per channel) during downtime; if isolation fails, replace the module (isolation components are not field-serviceable). Store spare Motorola MVME715P units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect high-current drivers.

Service and Guarantee Commitment

Motorola MVME715P refurbished units are backed by a 24-month warranty from Emerson, covering defects in digital I/O circuits, isolation components, overcurrent protection, and VMEbus interface. If Motorola MVME715P fails (e.g., in a military UGV), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks mission success or industrial production losses (up to $150,000 per hour for power grid systems).

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with digital I/O specialists), access to archived wiring diagrams and fault-diagnosis guides, and remote troubleshooting for daisy-chaining/overcurrent issues. Emerson maintains a global stock of high-current drivers, polyfuses, and isolation transformers for Motorola MVME715P until 2040, ensuring legacy discrete-control systems remain operational. This commitment underscores Emerson’s dedication to supporting the critical discrete-signal infrastructure of mission-critical automation.