Description

Detailed parameter table

| Parameter name | Parameter value |

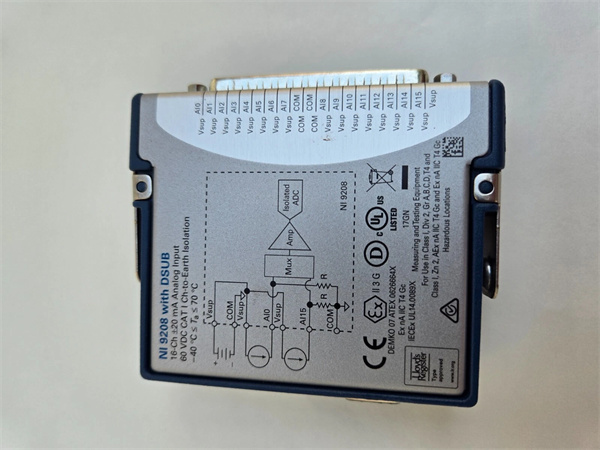

| Product model | NI 9208 |

| Manufacturer | National Instruments (NI) |

| Product category | C Series Analog Input Module (Universal Signal Compatibility) |

| Electrical performance (Analog Input) | 16 single-ended / 8 differential channels; Resolution: 16-bit; Max sampling rate: 100 kS/s (single-channel), 50 kS/s (multichannel, all 16 channels active); Input ranges: ±200 mV, ±1 V, ±5 V, ±10 V (software-selectable per channel); Input impedance: 10 GΩ (differential), 5 GΩ (single-ended) |

| Signal Compatibility | Universal input: Supports voltage, thermocouple (J, K, T, E, R, S, B, N), RTD (Pt100, Pt1000, Cu100), thermistor, and strain gauge (with external bridge completion); Built-in cold-junction compensation (CJC) for thermocouples (±0.5 °C accuracy) |

| Signal Integrity | Total Error (voltage): ±0.02% full scale (FS) at 25 °C; Thermocouple measurement accuracy: ±0.2 °C (J/K/T types); RTD measurement accuracy: ±0.1 °C (Pt100); Input-referred noise: < 3 µVrms (±1 V range); Common-mode rejection ratio (CMRR): > 80 dB (50 Hz/60 Hz) |

| Physical size | Dimensions (L×W×H): 89 mm × 54 mm × 32 mm (C Series form factor); Weight: Approximately 85 g; Mounting: C Series chassis slots (e.g., NI cRIO-9040, NI cDAQ-9178) |

| Interface type | C Series connector (for power and communication with chassis); 16-pin terminal block (TB-9213, included) for sensor wiring; LED indicators (module power, channel activity, error status) |

| Communication protocol | Chassis-dependent (EtherCAT via cRIO, USB/Ethernet via cDAQ); Compatible with NI-DAQmx driver; Supports DMA data transfer (via chassis); Integrates with LabVIEW, C/C++, Python, .NET APIs |

| Environmental requirements | Operating temperature: -40 °C to 70 °C (wider range than NI PXI-5105); Storage temperature: -40 °C to 85 °C; Relative humidity: 5% to 95% (non-condensing, with dewing); Vibration resistance: 5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine); IP Rating: IP20 (when installed in chassis) |

| Power requirements & Compatibility | Power consumption: 1.5 W (from chassis backplane); Compatible chassis: NI cRIO-9040, NI cDAQ-9178, NI cDAQ-9185/9189; Supported OS: Windows 10/11, NI Linux Real-Time (cRIO), macOS (cDAQ); Compatible software: LabVIEW 2018+, NI-DAQmx, NI TestStand |

| Calibration | User-calibratable via NI-DAQmx; Calibration interval: 12 months (recommended); Calibration sources: NIST-traceable voltage reference (e.g., NI 9172), NIST-traceable temperature bath (for thermocouples/RTDs) |

| Safety & Compliance | Compliance: CE, FCC Class B, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge); Isolation: 250 Vrms (input channels to chassis ground) |

NI-9208

Product introduction

The NI 9208 is a versatile C Series analog input module developed by National Instruments (NI), engineered for high-channel-count data acquisition in modular systems like CompactRIO (cRIO) and CompactDAQ (cDAQ). Unlike the NI PXI-5105 (a PXI digitizer focused on high-frequency signal capture), the NI 9208 specializes in universal signal measurement—supporting voltage, thermocouples, RTDs, thermistors, and strain gauges—making it ideal for applications where diverse sensor types need to be monitored simultaneously (e.g., industrial process control, building automation, academic research).

In modular DAQ setups, the NI 9208 acts as a “multi-sensor interface” that simplifies wiring and reduces system complexity. For example, paired with a NI cDAQ-9178 8-slot chassis, the NI 9208 monitors 8 thermocouples (tracking oven temperatures) and 8 voltage signals (measuring motor current) in a food processing plant. Its 16-bit resolution and ±0.02% FS voltage accuracy ensure precise data for quality control, while its -40 °C to 70 °C operating range withstands the plant’s harsh environmental conditions. Unlike the NI PXI-5105, which requires a bulky PXI chassis, the NI 9208 fits in compact cDAQ/cRIO chassis—enabling deployment in space-constrained areas like control cabinets or portable test kits.

Core advantages and technical highlights

Universal Signal Compatibility Reduces Hardware Complexity: The NI 9208’s ability to measure voltage, thermocouples, RTDs, thermistors, and strain gauges eliminates the need for multiple single-sensor modules—saving chassis slots and reducing wiring by 60% compared to using dedicated thermocouple or RTD modules. In a building automation system, for instance, the NI 9208 monitors 6 RTDs (HVAC duct temperatures), 6 thermocouples (boiler exhaust), and 4 voltage signals (fan motor current)—all with one module. This versatility also simplifies inventory management, as users no longer need to stock separate modules for different sensors—a key advantage over the NI PXI-5105 (voltage-only capture).

16 Channels for High-Density Monitoring: With 16 analog input channels (8 differential/16 single-ended), the NI 9208 offers higher channel density than the NI PXI-5105 (2 channels) or even multifunctional DAQ modules like the NI PXI-6255 (32 channels but larger form factor). This makes it ideal for applications requiring simultaneous monitoring of many sensors, such as a solar panel array test: the NI 9208 measures 16 panel voltage outputs (±10 V range) at 50 kS/s, tracking performance across the array. Its compact C Series size lets users stack multiple NI 9208 modules in a single chassis (e.g., 4 modules in a NI cDAQ-9178 for 64 channels)—scaling to large systems without the space requirements of PXI chassis.

Extreme Ruggedness for Harsh Environments: The NI 9208 operates from -40 °C to 70 °C and withstands 50 g shock—matching the ruggedness of the NI cRIO-9040 and far exceeding the NI PXI-5105’s 0 °C to 55 °C range. This makes it suitable for outdoor or industrial environments, such as a mining site where it monitors 8 thermocouples (gearbox temperatures) and 8 strain gauges (conveyor belt tension) in -20 °C winter conditions. Its 250 Vrms isolation also protects the chassis and connected computers from voltage transients (e.g., power surges), a safety feature missing from many low-cost analog input modules.

Seamless Integration with C Series Ecosystem: Designed for C Series chassis, the NI 9208 works seamlessly with NI cRIO-9040 (embedded control) and NI cDAQ-9178 (portable DAQ)—leveraging the chassis’ communication capabilities (EtherCAT, Ethernet, USB) for flexible deployment. A field technician, for example, uses the NI 9208 with a battery-powered NI cDAQ-9185 Ethernet chassis to test industrial sensors: the module’s universal inputs read thermocouples and voltage signals, while the chassis streams data to a laptop via Wi-Fi. Unlike the NI PXI-5105, which is tied to PXI systems, the NI 9208’s compatibility with multiple C Series chassis makes it adaptable to both fixed and mobile applications.

Typical application scenarios

In industrial process control, the NI 9208 monitors a chemical reactor system. Paired with a NI cRIO-9040 controller, it uses 8 differential channels to measure 4 RTDs (reactor wall temperature, ±0.1 °C accuracy) and 4 strain gauges (vessel pressure, via bridge voltage), plus 8 single-ended channels to track 8 chemical concentration sensors (±5 V range). The NI 9208’s built-in CJC ensures accurate thermocouple readings (if added later), while its 50 kS/s sampling rate captures dynamic changes in pressure and concentration. The NI cRIO-9040 uses this data to adjust heating and stirring rates—maintaining process stability and compliance with safety standards. Unlike the NI PXI-5105, which would require additional modules for temperature/strain measurement, the NI 9208 handles all inputs with one module.

In academic research, the NI 9208 supports a materials science lab’s thermal testing setup. The lab uses the module with a NI cDAQ-9174 4-slot chassis to measure 12 thermocouples (attached to a metal sample heated by a laser) and 4 voltage signals (laser power feedback). The NI 9208’s 16-bit resolution detects 30.5 µV changes in thermocouple voltage—enabling precise calculation of the sample’s temperature gradient. Its compatibility with LabVIEW lets students program automated data logging and real-time visualization, reinforcing concepts like heat transfer and sensor calibration. The module’s low cost (compared to the NI PXI-5105) also lets the lab deploy 5 test stations, supporting parallel student projects.

NI-9208

Related model recommendations

NI cRIO-9040: An embedded C Series controller that pairs with the NI 9208. The NI cRIO-9040 provides real-time control and FPGA processing, while the NI 9208 captures analog sensor data—ideal for rugged industrial applications (e.g., reactor control, mining equipment monitoring).

NI cDAQ-9178: An 8-slot CompactDAQ chassis compatible with the NI 9208. It enables portable or fixed DAQ systems with multiple NI 9208 modules (up to 64 channels) and USB/Ethernet connectivity—replacing bulky PXI chassis for high-channel-count applications.

NI 9213: A 16-channel thermocouple module complementary to the NI 9208. For systems requiring more thermocouple channels than the NI 9208 can handle, the NI 9213 adds 16 dedicated thermocouple inputs—expanding temperature monitoring capabilities.

NI PXI-5105: A PXI digitizer that works with the NI 9208 in mixed-speed tests. The NI 9208 captures low-speed sensor data (temperature, voltage), while the NI PXI-5105 captures high-frequency transients (e.g., voltage spikes)—covering both slow and fast signals in complex systems.

NI TB-9213: A terminal block included with the NI 9208, providing secure wiring for sensors (thermocouples, RTDs, voltage signals). It includes screw terminals and labeling for easy channel identification—simplifying installation and maintenance.

NI-DAQmx Driver: The core driver for the NI 9208, enabling configuration of input ranges, sensor types, and sampling rates. It optimizes data transfer via DMA (chassis-dependent) and supports software calibration—ensuring accurate measurements.

NI LabVIEW 2024: Essential software for programming the NI 9208. It includes pre-built VIs for sensor configuration (e.g., thermocouple type selection, RTD scaling) and data visualization—reducing development time by 50%.

NI 9945: A shielded cable for the NI 9208, connecting the module to the TB-9213 terminal block. It reduces noise in industrial environments (e.g., near motors or power lines), preserving the NI 9208’s signal integrity for low-level measurements (e.g., 200 mV strain gauge signals).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI 9208, power off the C Series chassis (e.g., NI cRIO-9040, NI cDAQ-9178) and wear an ESD wristband (±15 kV) to protect the module’s precision circuits. Align the NI 9208 with an empty chassis slot, ensuring the guide pins match the slot’s grooves. Push the module firmly until it clicks into place, then secure it with the chassis’ locking mechanism (if available). Connect the TB-9213 terminal block to the module using the included NI 9945 cable. Wire sensors to the terminal block: use twisted-pair shielded cables for thermocouples/RTDs (to reduce noise) and match input ranges to sensor outputs (e.g., ±200 mV for strain gauges). Power on the chassis and host PC, install the latest NI-DAQmx driver and LabVIEW, then use NI Measurement & Automation Explorer (MAX) to detect the NI 9208. Run a “Sensor Self-Test” in MAX (e.g., measure a known voltage or NIST-traceable temperature) to verify accuracy.

Maintenance suggestions: Calibrate the NI 9208 annually using a NIST-traceable voltage reference (e.g., NI 9172) for voltage inputs and a temperature bath for thermocouples/RTDs—maintaining ±0.02% FS voltage accuracy and ±0.2 °C temperature accuracy. Inspect the terminal block and cable connections quarterly: tighten loose screws (to prevent resistance-induced errors) and clean terminals with isopropyl alcohol (99.9% purity) to remove oxidation. If the NI 9208 reports noisy readings, check for ungrounded sensors or damaged shielded cables—replace cables if shielding is frayed. Avoid exposing the module to temperatures above 70 °C or humidity above 95%—extreme conditions can degrade its analog front-end and CJC circuitry. When replacing the module, ensure the chassis is powered off to prevent damage to the backplane.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI 9208, covering defects in materials and workmanship—including the analog front-end, CJC circuitry, and terminal block interface. For extended protection, the ServicePlus Standard Plan extends coverage to 4 years, including annual factory calibration (traceable to NIST) for all sensor types, priority technical support (4-hour response time for industrial/academic customers), and expedited repairs (turnaround time < 5 business days).

NI’s global technical team includes C Series specialists, offering 24/7 support for the NI 9208—assisting with sensor configuration, noise reduction, and software integration (e.g., LabVIEW-NI-DAQmx compatibility). Customers gain free access to exclusive resources: application notes on strain gauge testing with the NI 9208, LabVIEW example code for temperature monitoring, and a user community for sharing C Series module best practices. For out-of-warranty repairs, NI’s C Series Restore Service replaces aged components (e.g., ADC, CJC sensor) and verifies accuracy for all supported sensor types—restoring the NI 9208 to factory specs. This commitment reflects NI’s confidence in the module’s durability and dedication to supporting users’ high-channel, multi-sensor DAQ needs.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components