Description

Detailed parameter table

| Parameter name | Parameter value |

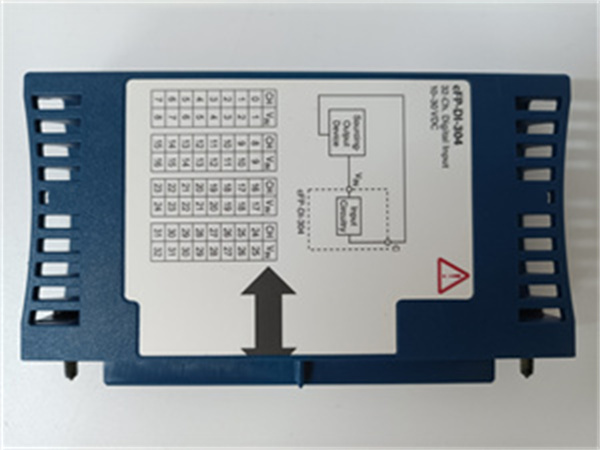

| Product model | NI CFP-DI-304 |

| Manufacturer | National Instruments (NI) |

| Product category | 16-Channel Digital Input Module (Compact FieldPoint) |

| Input Channels | 16 isolated digital input channels (configurable as 8 differential pairs) |

| Input Type | Sinking (NPN) and sourcing (PNP) compatible (software-selectable) |

| Voltage Range | 5-30 VDC (nominal); 4-32 VDC (operating) |

| Response Time | <1 ms (typical for 5-30 VDC signals) |

| Isolation Rating | 250 Vrms (channel-to-channel, channel-to-chassis) |

| Operating Temperature Range | -40 °C to 70 °C |

| Storage Temperature Range | -55 °C to 85 °C |

| Chassis Compatibility | NI Compact FieldPoint chassis (NI CFP-1804, NI CFP-1808, NI CFP-1810) |

| Dimensions (L×W×H) | 81 mm × 140 mm × 41 mm |

| Mounting | Integral to Compact FieldPoint chassis (no separate mounting required) |

NI CFP-DI-304

Product introduction

The NI CFP-DI-304 is a high-performance 16-channel digital input module designed for NI’s Compact FieldPoint industrial automation platform, engineered to capture discrete digital signals from sensors, switches, and industrial equipment in harsh environments. As a key component of the Compact FieldPoint ecosystem, NI CFP-DI-304 bridges field devices and control systems, enabling real-time monitoring of equipment status, process triggers, and safety interlocks.

This module’s versatility shines in its ability to accept both sinking (NPN) and sourcing (PNP) inputs, making it compatible with a wide range of industrial sensors—from proximity switches to limit detectors. When integrated with a NI CFP-1804 chassis and NI CFP-CB-1 connector block, NI CFP-DI-304 forms a robust digital acquisition system that thrives in extreme temperatures (-40 °C to 70 °C) and high-vibration settings. Whether deployed in factory automation, energy production, or transportation systems, NI CFP-DI-304 delivers reliable digital signal capture to support critical decision-making in industrial processes.

Core advantages and technical highlights

Industrial-grade isolation and ruggedness: NI CFP-DI-304 features 250 Vrms isolation between channels and the chassis, protecting sensitive control systems from voltage transients common in industrial environments—such as motor startups or power surges. Its wide operating temperature range (-40 °C to 70 °C) and resistance to vibration (5 g rms, 10-500 Hz) ensure reliable operation in challenging settings, from frozen food processing plants to desert oil fields. This ruggedness minimizes downtime in applications where equipment failure could halt production.

Dual input type compatibility: Unlike single-type digital modules, NI CFP-DI-304 supports both sinking (NPN) and sourcing (PNP) inputs via software configuration, eliminating the need for separate modules for different sensor types. In an automotive assembly line, for example, this allows the module to simultaneously monitor NPN-based photoelectric sensors and PNP-based limit switches—simplifying system design and reducing hardware costs. The 5-30 VDC voltage range further extends compatibility to legacy and modern sensors alike.

High-speed response for time-critical applications: With a typical response time of less than 1 ms, NI CFP-DI-304 captures fast transient signals, such as emergency stop triggers or conveyor jam alerts, ensuring timely system reactions. This speed is critical in safety-critical applications, where delays of even a few milliseconds could lead to equipment damage or safety incidents. When paired with LabVIEW Real-Time software, NI CFP-DI-304 enables deterministic control, with input states processed and acted upon within predictable time windows.

Typical application scenarios

In automotive manufacturing, NI CFP-DI-304 is deployed in body-in-white assembly lines to monitor 16 robotic weld cell statuses. Mounted in a NI CFP-1804 chassis near the weld cells, the module uses NI CFP-CB-1 to connect to proximity sensors (detecting part presence) and limit switches (verifying door closure). NI CFP-DI-304’s 1 ms response time ensures immediate detection of a misaligned part, triggering a safety shutdown to prevent weld errors. Its rugged design withstands weld spatter and electromagnetic interference from welding equipment, maintaining reliable operation in this harsh environment.

In renewable energy, NI CFP-DI-304 monitors 16 circuit breaker statuses in a solar farm’s combiner box. The module connects to auxiliary contacts of each breaker, transmitting “open/closed” states to a central SCADA system via the NI CFP-1810 chassis’ Ethernet port. NI CFP-DI-304’s -40 °C to 70 °C tolerance ensures functionality in extreme desert temperatures, while its 250 Vrms isolation protects the system from voltage spikes during breaker operations. This enables remote monitoring of grid connections, reducing the need for on-site inspections.

In water treatment, NI CFP-DI-304 tracks valve position feedback (open/closed) across 16 chemical dosing valves. The module interfaces with solenoid valve sensors via NI CFP-CB-1, providing real-time status to the plant’s PLC. Its compatibility with both NPN and PNP sensors allows the plant to use existing legacy valves alongside new equipment, avoiding costly sensor replacements. NI CFP-DI-304’s reliable performance ensures accurate dosing control, preventing chemical waste and ensuring regulatory compliance.

NI CFP-DI-304

Related model recommendations

NI CFP-DO-400: A 16-channel digital output module that complements NI CFP-DI-304 in control systems. While NI CFP-DI-304 monitors inputs, NI CFP-DO-400 triggers actuators like valves or alarms based on those inputs.

NI CFP-1804: A 4-slot Compact FieldPoint chassis that hosts NI CFP-DI-304, providing power, communication, and ruggedization for industrial deployments.

NI CFP-CB-1: A 36-terminal connector block that simplifies wiring between sensors and NI CFP-DI-304, with labeled terminals to reduce installation errors.

NI CFP-AI-100: An 8-channel analog input module that works with NI CFP-DI-304 in mixed-signal systems, capturing analog data (e.g., pressure) alongside digital status signals.

NI 9401: A C Series 32-channel digital input module, serving as a modern alternative to NI CFP-DI-304 in CompactRIO systems, with faster response times (500 ns).

NI CFP-CTR-502: A counter/timer module that pairs with NI CFP-DI-304 to measure pulse frequencies (e.g., flow meters) in addition to discrete digital states.

NI LabVIEW Real-Time: Software optimized for NI CFP-DI-304, enabling deterministic processing of digital inputs for time-critical control logic.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI CFP-DI-304, power off the Compact FieldPoint chassis (e.g., NI CFP-1804) and use ESD protection (wrist strap, mat) to prevent electrostatic damage. Verify the chassis has an available slot and that its firmware is updated via NI MAX for compatibility. Gather tools: a Phillips-head screwdriver (to secure the module) and wire strippers (for 22-14 AWG sensor wires). Connect NI CFP-CB-1 to NI CFP-DI-304 using the 37-pin D-sub connector, ensuring thumbscrews are tightened to seal against dust. Mount the chassis in a location with minimal vibration, within the module’s -40 °C to 70 °C operating range, and away from direct heat sources.

Maintenance suggestions: Inspect NI CFP-DI-304 connections quarterly via the NI CFP-CB-1 terminal block, checking for loose wires or corrosion—tighten terminals and clean with a dry cloth if needed. Test input responsiveness using a known good signal source (5-30 VDC) to verify channels are functioning correctly; unresponsive channels may indicate wiring issues or a need for firmware updates. Update NI-DAQmx drivers annually to ensure compatibility with the latest software. When replacing NI CFP-DI-304, save channel configurations (input type, voltage range) in NI MAX to simplify reconfiguration. Avoid exposing the module to temperatures beyond its rated range, as this can degrade isolation and input circuitry over time.

Service and guarantee commitment

National Instruments backs NI CFP-DI-304 with a 2-year standard warranty, covering defects in materials and workmanship—including isolation components and input circuitry. If NI CFP-DI-304 fails under normal use during the warranty period, NI provides free repair or replacement, with expedited service options for critical industrial systems to minimize downtime.

NI’s global technical support team is available 24/7 to assist with module configuration (input type selection, wiring diagrams), troubleshooting integration with Compact FieldPoint chassis, and optimizing response times for specific applications. Customers also receive lifetime access to driver updates, user manuals, and application notes for NI CFP-DI-304, ensuring long-term system compatibility and performance. This commitment reflects NI’s confidence in the module’s industrial-grade reliability and its role in critical automation systems.