Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

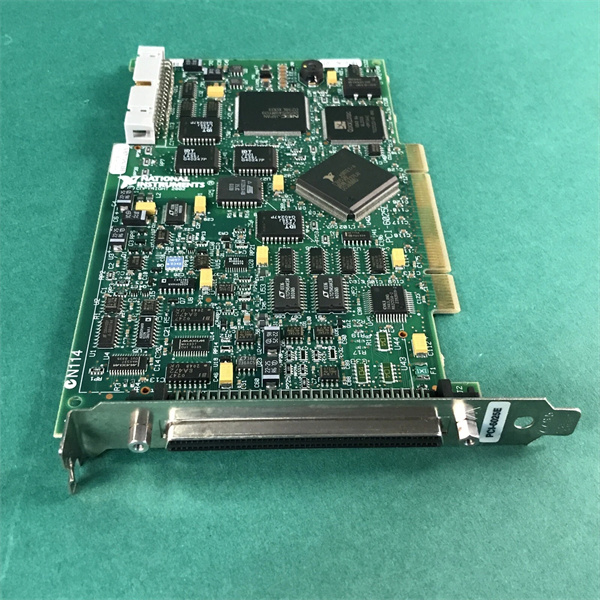

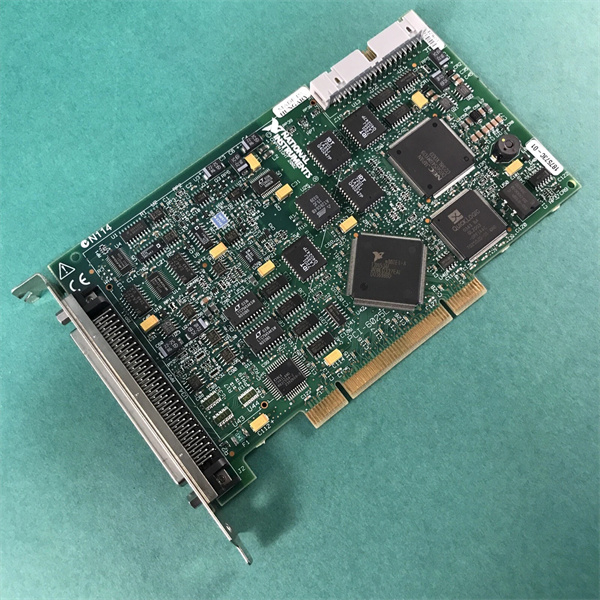

| Product Model | PCI-6025E |

| Manufacturer | National Instruments |

| Product Category | Multi-Function PCI Data Acquisition (DAQ) Device |

| Form Factor | 32-bit/33 MHz PCI (half-length card) |

| Analog Input (AI) | 16 single-ended / 8 differential channels; 12-bit resolution |

| AI Sampling Rate | Up to 200 kS/s (single-channel), 100 kS/s (multi-channel) |

| AI Input Range | ±10 V, ±5 V, ±2.5 V, ±1.25 V (software-selectable per channel) |

| Analog Output (AO) | 2 channels; 12-bit resolution |

| AO Output Range | ±10 V |

| Digital I/O (DIO) | 16 bidirectional channels (TTL-compatible) |

| Counters/Timers | 2 x 24-bit up/down counters (for event counting, pulse generation) |

| Connector Type | 68-pin female VHDCI (for interface to terminal blocks like BNC-2110) |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -20 °C to 70 °C |

| Relative Humidity | 10% to 90% non-condensing |

| Compliance Standards | CE, UL 61010-1, CAN/CSA C22.2 No. 61010-1, IEC 61010-1 |

| Software Compatibility | LabVIEW, LabWindows/CVI, .NET, C/C++, NI-DAQmx, Traditional NI-DAQ |

| Included Accessories | 68-pin VHDCI cable (0.5 m), driver CD, user manual |

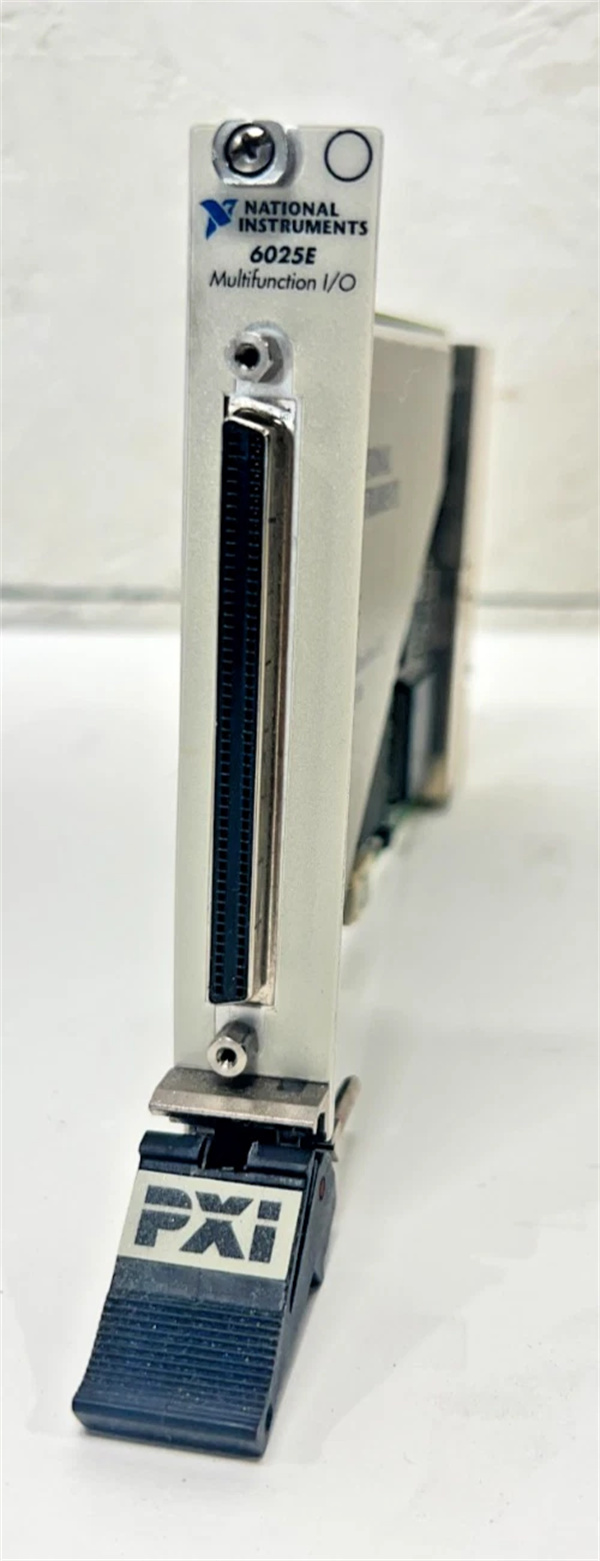

NI PCI-6025E

Product introduction

The National Instruments PCI-6025E is a legacy multi-function PCI DAQ device designed for reliable data acquisition in laboratory, industrial, and educational environments. As part of NI’s E-Series—renowned for balance between performance and cost—it delivers versatile analog input/output, digital I/O, and counter/timer functionality, making it ideal for applications ranging from basic sensor monitoring to automated test.

At its core, the PCI-6025E simplifies signal conversion: it transforms analog sensor signals (e.g., from thermocouples or pressure transducers) into digital data for computer processing, while also generating analog outputs to control actuators or stimulate DUTs (devices under test). Its 68-pin VHDCI connector seamlessly pairs with terminal blocks like the NI BNC-2110, translating dense PCI connections into user-friendly BNC ports for easy sensor/instrument integration. Whether used to log temperature data in a research lab or control a small-scale industrial process, the PCI-6025E offers the flexibility and durability needed for long-term deployment.

A key strength of the PCI-6025E is its backward compatibility with Traditional NI-DAQ (for legacy systems) and support for NI-DAQmx (for modern software workflows), ensuring it integrates with both older test setups and new applications. This versatility has made it a staple in environments where reliable, cost-effective DAQ is critical.

Core advantages and technical highlights

Balanced Performance for Mixed-Signal Applications: The PCI-6025E combines 16 AI channels (12-bit, 200 kS/s) and 2 AO channels (12-bit) with 16 DIO lines—all in a single PCI card. This eliminates the need for multiple specialized cards, reducing system cost and PCI slot usage. For example, in a university lab, it can simultaneously measure 8 differential temperature signals (AI), generate a 5 V control signal (AO) for a fan, and monitor 4 limit switches (DIO)—all with one device.

Flexible Input Ranges for Diverse Sensors: With software-selectable AI ranges (±10 V to ±1.25 V), the PCI-6025E adapts to sensors of varying output levels. A ±1.25 V range is ideal for low-voltage sensors like strain gauges (via signal conditioning), while ±10 V accommodates high-output devices like accelerometers. This flexibility avoids the need for external signal scaling, simplifying setup and reducing measurement errors.

Seamless Integration with Terminal Blocks: The PCI-6025E’s 68-pin VHDCI connector is designed to work with terminal blocks such as the NI BNC-2110. This pairing is critical for usability: the BNC-2110 converts the card’s dense connector into 16 BNC ports, allowing engineers to quickly connect/disconnect sensors or test equipment without specialized tools. For field service teams, this means faster reconfiguration during on-site diagnostics.

Legacy Compatibility with Modern Support: Unlike newer DAQ devices that drop support for older software, the PCI-6025E works with both Traditional NI-DAQ (for legacy LabVIEW 7.x/8.x applications) and NI-DAQmx (for current software). This is invaluable for industries with long-lived test systems—e.g., aerospace or automotive—where replacing legacy software is costly. NI also provides ongoing driver updates for the PCI-6025E, ensuring compatibility with modern operating systems like Windows 10.

Typical application scenarios

Educational Labs and Training: In engineering classrooms, the PCI-6025E is a teaching tool for introducing DAQ concepts. Paired with the NI BNC-2110, students connect it to microphones (AI) to measure sound waves, function generators (AO) to learn signal generation, and LEDs (DIO) to practice digital control. Its 12-bit resolution and moderate sampling rate strike a balance between simplicity (for beginners) and real-world relevance (mirroring industrial DAQ systems).

Industrial Process Monitoring: In small manufacturing facilities, the PCI-6025E monitors critical process parameters like temperature, pressure, and flow. For example, in a food packaging plant, it can sample 8 thermocouples (AI) on a heating tunnel every 10 ms, ensuring product temperatures stay within safety limits. The card’s 16 DIO lines also trigger alarms if temperatures exceed thresholds, while its AO channels adjust heating element power—creating a closed-loop control system.

Legacy Test System Upgrades: Many aerospace and defense organizations rely on the PCI-6025E to maintain legacy test setups (e.g., for avionics component testing). Its compatibility with Traditional NI-DAQ allows it to replace failed older DAQ cards without rewriting decades-old test code. When paired with the NI BNC-2110, it continues to interface with existing sensors and instruments, extending the life of critical test equipment.

NI PCI-6025E

Related model recommendations

NI BNC-2110: A BNC terminal block that pairs directly with the PCI-6025E’s 68-pin VHDCI connector. It converts the card’s AI/AO/DIO signals into 16 BNC ports, simplifying connections to sensors, oscilloscopes, or function generators—critical for lab or field use.

NI PCI-6035E: A higher-performance E-Series sibling of the PCI-6025E. It offers 16-bit AI resolution (vs. 12-bit) and 500 kS/s sampling rate, making it a upgrade for applications requiring higher precision (e.g., medical device testing).

NI USB-6211: A USB-based E-Series DAQ device that serves as a portable alternative to the PCI-6025E. It offers similar AI/AO/DIO specs but connects via USB, ideal for mobile testing (e.g., on-site equipment diagnostics) where PCI slots are unavailable.

NI SCXI-1001: A 12-slot SCXI chassis that complements the PCI-6025E for high-channel-count or harsh-environment applications. The PCI-6025E controls SCXI modules (e.g., SCXI-1140 for thermocouples) via a SCXI-1349 cable, expanding AI channels to 128+.

NI 1978: A 2 m 68-pin VHDCI extension cable for the PCI-6025E. It extends the distance between the card (in a desktop PC) and the BNC-2110 (on a benchtop), useful for space-constrained setups.

NI LabVIEW Base Package: Software for programming the PCI-6025E. It provides graphical tools to design DAQ workflows—e.g., real-time data logging, signal analysis, or closed-loop control—without writing complex code.

Installation, commissioning and maintenance instructions

Installation Preparation: Before installing the PCI-6025E, power off the PC and ensure it has an available 32-bit PCI slot (half-length compatible). Tools needed include a Phillips-head screwdriver (to open the PC case) and anti-static wristband (to prevent ESD damage). First, install NI-DAQmx (or Traditional NI-DAQ for legacy systems) from the included CD or NI’s website. Ground yourself, open the PC case, align the PCI-6025E with the PCI slot, and press firmly until seated. Secure the card with a screw, close the case, and power on the PC—Windows will automatically detect the card if drivers are installed. Finally, connect the PCI-6025E to a terminal block (e.g., BNC-2110) using the included VHDCI cable.

Maintenance Suggestions: For daily use, inspect the PCI-6025E’s VHDCI connector for dust or bent pins—clean with compressed air if needed. Check the extension cable (if used) for fraying, as damaged cables cause signal loss. To maintain accuracy, calibrate the card annually using NI’s Calibration Services, which verifies AI/AO linearity and offset. If the card fails to detect sensors, first confirm the BNC-2110 connections (e.g., AI channels are paired correctly) and update drivers to the latest version. For legacy systems, avoid upgrading to untested operating systems—NI provides a compatibility matrix for the PCI-6025E on its website.

Service and guarantee commitment

National Instruments backs the PCI-6025E with a 1-year standard warranty (extendable to 3 years) covering defects in materials and workmanship. This warranty reflects NI’s confidence in the card’s durability, even in industrial environments with temperature fluctuations (0 °C to 55 °C).

For technical support, NI’s global team offers 24/7 assistance via email, phone, and online forums—helping users troubleshoot driver issues, resolve compatibility with legacy software, or optimize sampling rates. NI also provides repair services for the PCI-6025E, including component-level fixes for failed circuits, ensuring legacy systems remain operational.

Users gain access to free online resources, including the PCI-6025E user manual, application notes (e.g., “Using E-Series DAQ with SCXI Chassis”), and video tutorials for LabVIEW integration. For organizations relying on the PCI-6025E in critical test setups, NI offers extended support contracts that include priority technical assistance and discounted calibration services—delivering long-term peace of mind.