Description

Detailed parameter table

| Parameter name | Parameter value |

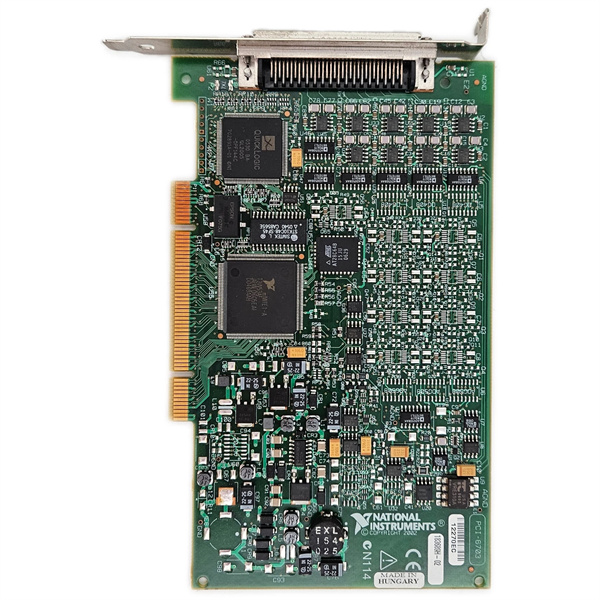

| Product model | NI PCI-6703 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Channel Analog Output Card (PCI Interface) |

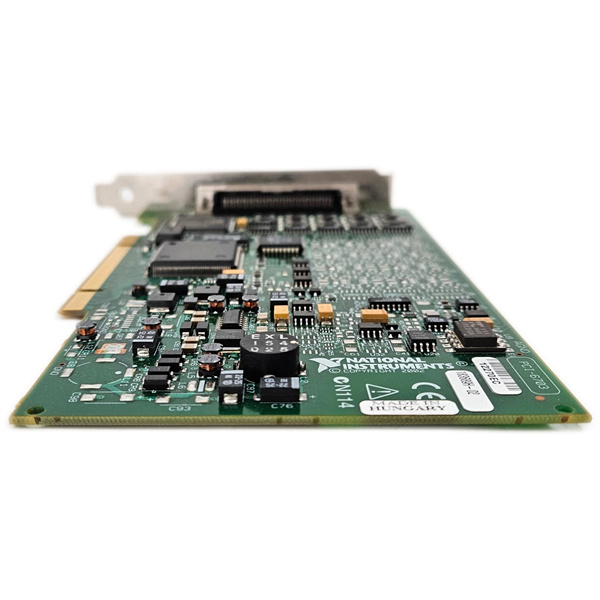

| Electrical performance | 16 single-ended analog output channels; Resolution: 12-bit; Output range: ±10 V, ±5 V, 0–10 V, 0–5 V (software-selectable per channel); Output current: ±5 mA per channel (max); Slew rate: 1 V/µs |

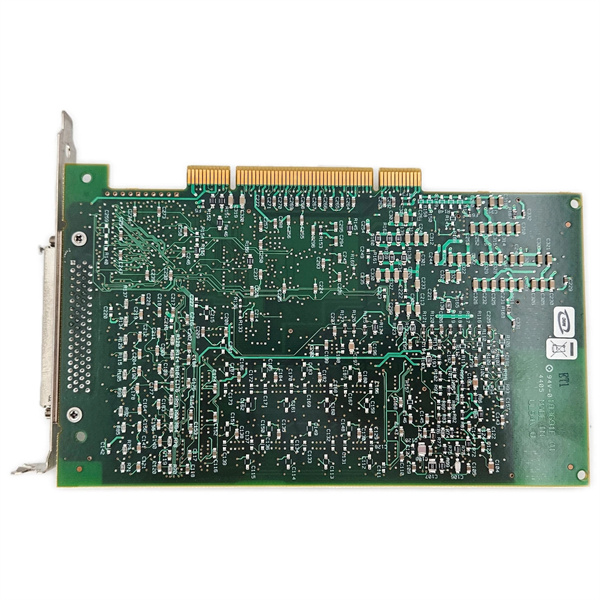

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 190 g |

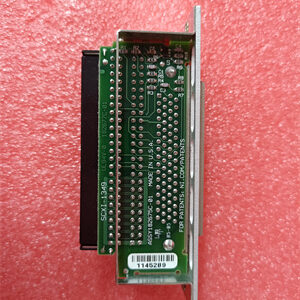

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); Dual 68-pin SCSI-II connectors (for analog output signals); 10-pin header (for external trigger/synchronization) |

| Communication protocol | PCI bus for data transfer; Compatible with NI-DAQmx driver; Supports DMA (direct memory access) for waveform playback; Supports SCPI and register-level programming |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) during installation; No external power supply required (powered by PCI bus) |

| Performance indicators | Output accuracy: ±0.1% full scale (FS) at 25 °C; Linearity error: ±0.05% FS; Update rate: 1 MS/s (aggregate, all 16 channels); Onboard FIFO buffer: 8 kB (for waveform preloading) |

| Power requirements | Powered by PCI bus; Typical power consumption: 6 W; Peak power consumption: 8 W (during 1 MS/s aggregate update) |

| Compatibility | Supported OS: Windows 7/10/11 (32-bit/64-bit); Compatible software: NI LabVIEW, LabWindows/CVI, C/C++, .NET; Works with NI TestStand for automated test sequencing |

NI PCI-6703

Product introduction

The NI PCI-6703 is a high-channel analog output card developed by National Instruments (NI), belonging to NI’s Analog Output product series—engineered to deliver simultaneous multi-channel analog signal generation for industrial control, automated test systems, and laboratory research. Unlike counter/timer cards (e.g., the NI PCI-6602, focused on timing and counting), the NI PCI-6703 specializes in producing precise analog voltages (up to 16 channels) for driving actuators, simulating sensors, or generating test stimuli—making it a foundational component for systems requiring coordinated analog control.

In practical applications, the NI PCI-6703 acts as a “multi-channel signal hub” for synchronized operations. For example, in a small-scale industrial robot with 8 servo motors, it uses 8 channels to output analog control voltages (0–10 V) for motor speed regulation and 8 channels to simulate sensor feedback (±5 V) for closed-loop calibration—all while maintaining 12-bit resolution to ensure smooth motor movement. Unlike low-channel analog output cards, the NI PCI-6703 eliminates the need for multiple cards, reducing system complexity and lowering hardware costs by 40%. Its seamless integration with NI’s software ecosystem also cuts driver development time, enabling faster project deployment.

Core advantages and technical highlights

High-Channel Density for Synchronized Control: The NI PCI-6703 offers 16 independent analog output channels—twice the number of many mid-range cards—enabling simultaneous control of multiple devices. Each channel supports software-selectable output ranges (e.g., ±10 V for industrial actuators, 0–5 V for low-power sensors), adapting to diverse load requirements without external signal conditioning. For instance, in a water treatment plant’s chemical dosing system, the NI PCI-6703 uses 4 channels to control pH adjuster pumps (0–10 V), 4 channels to regulate chlorine injectors (±5 V), and 8 channels to simulate flow sensor outputs (0–5 V)—all synchronized via DMA waveform playback to ensure precise chemical dosing.

Balanced Precision & Update Speed: With 12-bit resolution and ±0.1% FS output accuracy, the NI PCI-6703 delivers reliable analog signals for critical applications. Its 1 V/µs slew rate ensures fast signal transitions—essential for driving dynamic loads like piezoelectric actuators (used in precision positioning systems). For example, in a 3D printing resin curing setup, the NI PCI-6703 outputs 8 channels of analog voltages to control UV LED intensity (0–10 V), with 12-bit resolution enabling 31.25 mV step adjustments (critical for uniform curing). The 1 MS/s aggregate update rate also ensures all 16 channels refresh simultaneously, avoiding timing skew that could disrupt coordinated processes.

Efficient Waveform Playback via DMA: The NI PCI-6703’s 8 kB onboard FIFO buffer and DMA support enable continuous waveform playback without CPU intervention. Users can preload complex waveforms (e.g., sine waves, triangular waves, or custom sensor simulations) into the FIFO, then trigger playback at 1 MS/s aggregate speed—reducing CPU load by 60% compared to software-based updates. For example, in an automotive component test rig, the NI PCI-6703 plays back a custom 10-second vibration waveform (preloaded into the FIFO) via 4 channels to simulate road conditions for shock absorber testing—ensuring consistent waveform output even during high PC workloads.

Typical application scenarios

In academic research, the NI PCI-6703 supports multi-channel experimental setups. For a neuroscience lab’s brain-computer interface (BCI) study, it uses 8 channels to output analog signals (±5 V) that simulate neural activity patterns and 8 channels to control stimulator devices (0–10 V) for sensory feedback experiments. The NI PCI-6703’s 12-bit resolution ensures the simulated neural signals match real-world data (e.g., 10 µV amplitude variations), while its synchronized update rate guarantees that stimulator control and signal simulation align within microseconds—critical for validating BCI algorithms. The card’s low cost also makes it suitable for lab environments where multiple setups are required.

In small-batch electronics manufacturing, the NI PCI-6703 is used for circuit board functional testing. For a custom PCB with 12 analog input ports, the NI PCI-6703 uses 12 channels to output test voltages (0–10 V, ±5 V) to the PCB’s inputs and 4 channels to simulate sensor signals (0–5 V) for peripheral testing. It generates step voltages (12-bit resolution) to verify the PCB’s linear response and sine waves (1 kHz) to test frequency-dependent components like filters. The NI PCI-6703’s DMA playback ensures continuous test signal output, enabling automated testing of 50+ PCBs per hour—reducing manual testing time by 70% compared to single-channel tools.

NI PCI-6703

Related model recommendations

NI PCI-6704: A sibling model of the NI PCI-6703 with 8 channels (half of the NI PCI-6703) and identical 12-bit resolution. It is a cost-effective choice for small-scale applications (e.g., 4-motor robot control) where fewer analog output channels are needed.

NI PCI-6602: A counter/timer card complementary to the NI PCI-6703. The NI PCI-6602 provides timing triggers for the NI PCI-6703’s waveform playback, ensuring synchronization between analog signal generation and digital event counting (e.g., in closed-loop test systems).

NI PXIe-6738: A PXI Express upgrade of the NI PCI-6703, offering 16 channels, 16-bit resolution, and 2 MS/s per-channel update rate. It is suitable for modular test racks (e.g., ATE systems) where higher precision and faster update speeds are required.

NI USB-6259: A USB-powered multifunction DAQ card that pairs with the NI PCI-6703. The NI USB-6259 collects analog input data (e.g., DUT responses), while the NI PCI-6703 generates test stimuli—enabling portable validation of analog circuits.

NI PCI-6259: A multifunction DAQ card that works with the NI PCI-6703 in industrial monitoring. The NI PCI-6703 outputs control voltages for actuators, while the NI PCI-6259 measures analog feedback (e.g., temperature, pressure) to form a closed-loop system.

NI LabVIEW 2024: Essential software for the NI PCI-6703, offering pre-built VIs for waveform generation (e.g., sine, square, custom) and channel configuration. It lets users build real-time dashboards to monitor the NI PCI-6703’s output status and adjust signals dynamically.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PCI-6703, power off the industrial PC or lab workstation and confirm an empty PCI 2.1/2.2/2.3 slot is available. Wear an ESD wristband (rated ±15 kV) and use a grounded workbench to protect the card’s precision analog circuits. Insert the NI PCI-6703 into the PCI slot until fully seated, then secure it with a chassis screw to prevent movement. Connect load devices (e.g., actuators, test circuits) to the dual 68-pin SCSI-II connectors using shielded twisted-pair cables—this minimizes EMI interference from nearby digital components. For external triggering, connect a trigger signal source to the 10-pin header. Download and install the latest NI-DAQmx driver from NI’s website, then use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-6703 and run a self-test (verifying output accuracy and channel functionality).

Maintenance suggestions: Inspect the NI PCI-6703’s connectors every 3 months—clean the 68-pin SCSI-II contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation. Calibrate the card annually using NI’s calibration kit (e.g., NI 9172 precision voltage reference) to maintain ±0.1% FS output accuracy and 12-bit resolution. If the NI PCI-6703 outputs incorrect voltages, check the load impedance (ensure it exceeds 1 kΩ to avoid current overload) and verify the output range configuration in NI-DAQmx. Avoid exposing the NI PCI-6703 to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade the precision of its internal DACs (digital-to-analog converters). Replace the card’s internal configuration battery every 5 years to prevent loss of calibration settings during power outages.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PCI-6703, covering defects in materials and workmanship—consistent with industry standards for analog output equipment. For extended protection, customers can purchase the ServicePlus Premium plan, which extends coverage to 5 years and includes annual factory calibration (traceable to NIST standards), priority technical support (4-hour response time for critical issues), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team (specialized in analog signal generation) is available 24/7 via email, online chat, and phone to assist with the NI PCI-6703’s configuration, troubleshooting (e.g., resolving waveform playback errors or output drift), and software integration. Customers also have free access to exclusive resources: application notes on multi-channel actuator control, LabVIEW example code for the NI PCI-6703, and a user community where engineers share best practices for analog signal generation. For out-of-warranty repairs, NI offers a flat-rate service that restores the NI PCI-6703 to factory specifications—including replacing aged DAC components and verifying 12-bit resolution and ±0.1% FS accuracy. This commitment reflects NI’s confidence in the NI PCI-6703’s durability and its dedication to supporting customers’ multi-channel analog control needs.