Description

Detailed parameter table

| Parameter name | Parameter value |

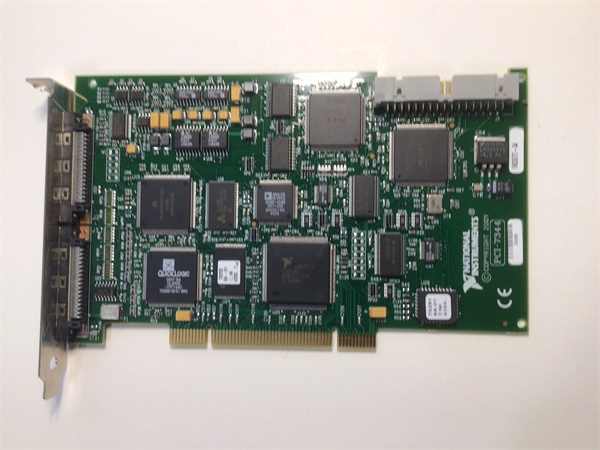

| Product model | NI PCI-7344 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Speed High-Precision 4-Axis Motion Controller Card (PCI Interface) |

| Electrical performance | 4 independent motion axes; Supports servo motors (analog torque/velocity/position mode) and stepper motors (pulse/direction, CW/CCW); Position range: ±2³¹ counts; Position resolution: 1 count (50 nm with 20,000-line encoders); Max pulse output frequency: 20 MHz per axis (2× faster than NI PCI-7324) |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 22 mm (standard PCI form factor, with enhanced heat dissipation); Weight: Approximately 230 g (heavier than NI PCI-7324 due to high-frequency circuitry) |

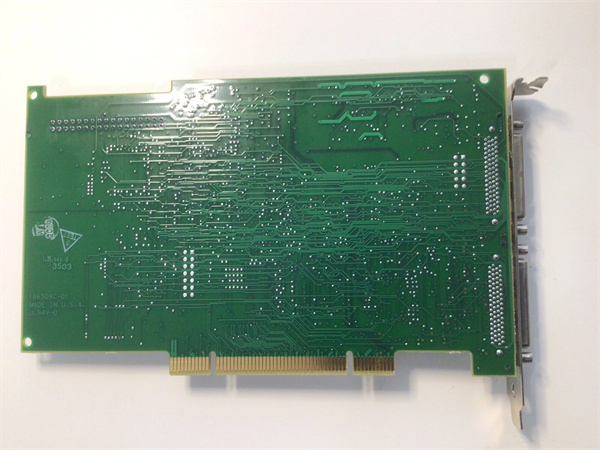

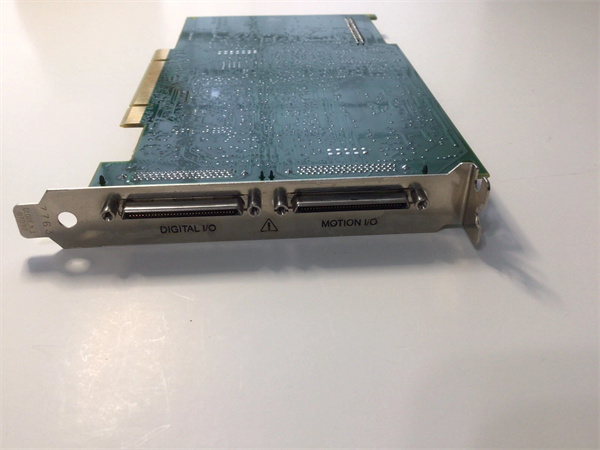

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz, optimized for motion data); 68-pin SCSI-II connector (motor control signals: encoder inputs, pulse outputs, limit/home switches); 10-pin header (external trigger/synchronization); RTSI bus connector (8-line, low-latency); 2-pin external power header (for high-current encoder supply) |

| Communication protocol | PCI bus with motion-optimized DMA (scatter-gather); Compatible with NI-Motion driver (v18.0+); Supports SCPI, register-level programming, and LabVIEW FPGA (for custom motion logic); Integrates with NI Motion Assistant (v2024+) |

| Environmental requirements | Operating temperature: 0 °C to 55 °C (enhanced thermal design for 20 MHz operation); Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2.5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (card) + optional external 5 VDC (encoder supply); Requires external motor power (12–72 VDC, for high-torque servos) |

| Performance indicators | Position accuracy: ±0.5 counts (after calibration, 50% better than NI PCI-7324); Velocity range: 1 count/s to 2×10⁹ counts/s; Acceleration/deceleration: Trapezoidal, S-curve (100+ configurable profiles); Motion modes: Point-to-point, linear/circular interpolation, electronic gearing, cam profiling, jogging; Encoder input: Quadrature (A/B/Z), up to 20 MHz (differential signaling supported) |

| Power requirements | Typical power consumption: 8 W (card only); Peak power consumption: 12 W (during 20 MHz pulse output); Encoder power: Optional external 5 VDC (1 A max); Motor power: External (dependent on motor, 12–72 VDC) |

| Compatibility | Supported OS: Windows 7/10/11 (32-bit/64-bit); Compatible software: NI LabVIEW, LabWindows/CVI, C/C++, .NET, Python (via NI-Motion API); Works with NI Motion Assistant (graphical cam/gear design); Integrates with NI TestStand and Semiconductor Test Suite |

NI PCI-7344

Product introduction

The NI PCI-7344 is a high-speed high-precision 4-axis motion controller card developed by National Instruments (NI), serving as the flagship model in NI’s PCI-based Motion Control series—engineered to outperform entry-level 4-axis models like the NI PCI-7324 and scaled-axis variants like the NI PCI-7342 (2-axis) and NI PCI-7334 (3-axis). It retains the series’ signature closed-loop precision but elevates performance with 20 MHz pulse output (double the NI PCI-7324’s 10 MHz), advanced motion modes (electronic gearing, cam profiling), and differential encoder support—making it the top choice for demanding 4-axis applications such as semiconductor wafer transfer, precision CNC milling, and automated robotic inspection.

In automation systems, the NI PCI-7344 acts as a “high-performance motion hub” for complex 4-axis coordination. For example, in a semiconductor wafer handling robot, it controls the X, Y, Z, and rotation axes simultaneously—using 20 MHz pulse output to drive high-torque servos (ensuring 50 nm position resolution) and differential encoder feedback to reject electromagnetic interference (EMI) from nearby wafer processing tools. Its optimized PCI DMA and RTSI bus also synchronize motion with NI PCI-6259 DAQ cards and NI PCIe-6733 analog output cards, enabling the robot to trigger wafer alignment checks and process gas flow adjustments at sub-millisecond waypoints—critical for meeting semiconductor industry’s 300 mm wafer handling standards.

Core advantages and technical highlights

20 MHz High-Frequency Pulse Output for Ultra-Fast Motion: The NI PCI-7344 delivers 20 MHz pulse output per axis—twice the speed of the NI PCI-7324—enabling faster motor acceleration and higher top velocities. In a 4-axis precision CNC mill, this translates to a 40% reduction in cycle time for aluminum alloy part machining: the mill’s X/Y axes (driven by NI PCI-7344) move at 2 m/s (vs. 1.2 m/s with NI PCI-7324) while maintaining 50 nm resolution, ensuring both speed and surface finish (Ra < 0.8 μm). The high-frequency output also supports smaller step sizes (50 nm with 20,000-line encoders), ideal for micro-machining applications like medical device component production.

Advanced Motion Modes for Complex Coordination: Unlike the NI PCI-7324 (limited to linear/circular interpolation), the NI PCI-7344 adds electronic gearing and cam profiling—critical for applications requiring master-slave axis synchronization. In an automotive transmission test rig, for example, the NI PCI-7344 uses electronic gearing to link the master axis (simulating engine RPM) to three slave axes (simulating gear shafts), maintaining a precise 1:2.5 gear ratio even as engine RPM varies from 1,000 to 8,000 RPM. For packaging machines, its cam profiling feature preloads custom motion profiles (e.g., “wrap-and-seal” sequences) into onboard memory, enabling smooth, repeatable motion without CPU intervention—reducing packaging error rates by 25% compared to generic controllers.

Differential Encoder Support & EMI Immunity: The NI PCI-7344 supports differential quadrature encoders (up to 20 MHz), a key upgrade from the NI PCI-7324’s single-ended inputs. Differential signaling rejects EMI from high-voltage equipment (e.g., welding machines, laser cutters), ensuring stable position feedback in noisy industrial environments. In a solar panel cell sorting system, for instance, the NI PCI-7344’s differential encoder inputs (connected to cell transport belt encoders) maintain ±0.5 count accuracy even when the system is located 5 meters from a 10 kW laser scribing tool—something the NI PCI-7324’s single-ended inputs would struggle with due to signal noise.

Optimized DMA & Multi-Device Synchronization: The NI PCI-7344 features motion-optimized scatter-gather DMA, which reduces CPU load by 60% compared to the NI PCI-7324 during high-speed motion. In a 4-axis robotic pick-and-place machine handling 1,000 components per hour, this ensures the PC can simultaneously run vision inspection software (for component alignment) while the NI PCI-7344 controls robot motion. Its RTSI bus also supports sub-100 ns synchronization with other NI devices: in a semiconductor wafer inspection system, the NI PCI-7344 triggers a NI PCI-6259 DAQ card to capture wafer surface images at 100 waypoints per second, with motion and imaging aligned within 50 ns—critical for detecting 1 μm-scale defects.

Typical application scenarios

In semiconductor manufacturing, the NI PCI-7344 powers 4-axis wafer transfer robots in cleanrooms (Class 100). The robot uses X/Y axes for linear movement (2 m/s, 50 nm resolution), Z axis for vertical lifting (0.8 m/s), and R axis for wafer rotation (300°/s)—all controlled by NI PCI-7344. The controller’s differential encoder inputs reject EMI from nearby ion implanters, while its 20 MHz pulse output ensures the robot completes a wafer transfer (from cassette to inspection stage) in 1.2 seconds (vs. 2 seconds with NI PCI-7324)—increasing factory throughput by 33%. RTSI synchronization with a NI PCIe-6733 analog output card also adjusts the robot’s vacuum grip pressure based on wafer thickness (measured by a DAQ card), preventing wafer breakage (a $5,000+ loss per incident).

In medical device manufacturing, the NI PCI-7344 controls 4-axis CNC lathes for stainless steel surgical scalpel production. The lathe’s X (radial) and Z (axial) axes machine the scalpel’s blade contour (Ra < 0.4 μm) using NI PCI-7344’s linear interpolation, while the C (spindle) and U (tool offset) axes use electronic gearing to maintain a 1:1.2 spindle-to-tool ratio—ensuring consistent blade sharpness across 10,000+ units. The controller’s S-curve acceleration (configurable via NI Motion Assistant) reduces tool vibration, extending carbide tool life by 30% and lowering production costs. LabVIEW integration also logs every lathe’s motion data (position, velocity, torque) for FDA 21 CFR Part 11 compliance, enabling full traceability of each scalpel’s manufacturing process.

NI PCI-7344

Related model recommendations

NI PCI-7324: The entry-level 4-axis sibling of NI PCI-7344, offering 10 MHz pulse output (vs. 20 MHz) and no electronic gearing. It is a cost-effective alternative for non-high-speed 4-axis applications (e.g., basic robotic assembly) and a stepping stone to NI PCI-7344 for users scaling to faster workflows.

NI PCI-7342: The 2-axis variant of NI PCI-7344, with identical 20 MHz pulse output but fewer axes. It suits 2-axis high-speed applications (e.g., 2D laser cutting) and can be paired with NI PCI-7344 in hybrid systems (e.g., 4-axis robot + 2-axis conveyor control).

NI PCI-6259: A multifunction DAQ card that pairs with NI PCI-7344 for closed-loop motion+measurement. The NI PCI-7344 controls motion, while the NI PCI-6259 acquires force/torque data (e.g., in robotic assembly) to adjust motion parameters in real time.

NI Motion Assistant 2024: Essential software for NI PCI-7344, providing graphical tools to design cam profiles and electronic gear ratios—no low-level programming needed. It lets users test 4-axis sequences offline (e.g., wafer transfer paths) before deploying to NI PCI-7344, reducing downtime.

NI TB-2707-D: A differential encoder terminal block for NI PCI-7344, supporting differential A/B/Z signals and surge protection (±2 kV ESD). It simplifies wiring of high-frequency encoders and ensures EMI immunity—critical for NI PCI-7344’s 20 MHz performance.

NI PCIe-8135: A PXIe controller that complements NI PCI-7344 in modular test systems. It runs LabVIEW software to coordinate NI PCI-7344 (motion) with other PXIe modules (e.g., NI PXIe-6733 for analog control) in semiconductor test racks.

NI SM3322: A 2-channel servo motor driver compatible with NI PCI-7344. It delivers 2 A continuous current (up to 5 A peak) to high-torque servos, perfectly matching NI PCI-7344’s 20 MHz pulse output for fast, precise motion.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCI-7344, power off the industrial PC and confirm an empty PCI 2.1/2.2/2.3 slot with 5 mm of adjacent space (for heat dissipation). Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s high-frequency circuitry. Insert NI PCI-7344 firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. For differential encoders, use twisted-pair shielded cables (100 Ω impedance) to connect to the 68-pin SCSI-II connector via NI TB-2707-D terminal block—ground the shield at both ends to maximize EMI rejection. Install the latest NI-Motion driver (v18.0+) and NI Motion Assistant, then use NI Measurement & Automation Explorer (MAX) to run a “High-Speed Motion Self-Test” (unique to NI PCI-7344) to verify 20 MHz pulse output and differential encoder feedback.

Maintenance suggestions: Calibrate NI PCI-7344 every 3 months (more frequent than NI PCI-7324’s quarterly schedule) using encoder reference marks and a laser interferometer (for linear axes) to maintain ±0.5 count accuracy. Inspect the 68-pin connector and RTSI bus monthly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth, and check shielded encoder cables for damage (e.g., frayed insulation) that could compromise EMI immunity. If NI PCI-7344 experiences gear ratio errors in electronic gearing mode, verify the master/slave axis encoder resolution settings in NI-Motion and update the card’s firmware via MAX. Avoid exposing NI PCI-7344 to temperatures above 50 °C (5 °C lower than its 55 °C limit) to prevent thermal drift of high-frequency oscillators. Replace the card’s external encoder power supply (if used) every 2 years to ensure stable 5 VDC output.

Service and guarantee commitment

National Instruments (NI) provides a 3-year standard warranty for NI PCI-7344—longer than the 2-year coverage of NI PCI-7324 and NI PCI-7342—covering defects in high-frequency circuitry, differential encoder inputs, and motion control logic. For extended protection, the ServicePlus Premium Motion Plan extends coverage to 7 years, including: annual NIST-traceable calibration (with laser interferometer verification for linear axes), priority technical support (1-hour response time for semiconductor/medical industry customers), and expedited repairs (turnaround time < 2 business days with loaner card options for critical downtime scenarios).

NI’s global technical team includes specialists in high-speed motion control, offering 24/7 support for NI PCI-7344’s advanced features (e.g., cam profile tuning, differential encoder troubleshooting). Customers gain exclusive access to industry-specific resources: application notes on semiconductor wafer handling with NI PCI-7344, LabVIEW FPGA example code for custom electronic gearing, and a dedicated user forum for sharing 4-axis high-speed motion best practices. For out-of-warranty repairs, NI’s Precision Motion Restore Service replaces aged high-frequency components (e.g., 20 MHz oscillators) and verifies all performance metrics (20 MHz pulse output, ±0.5 count accuracy)—restoring NI PCI-7344 to factory specs. This commitment reflects NI’s understanding that NI PCI-7344 powers mission-critical workflows, where downtime and precision errors directly impact revenue and compliance.