Description

Detailed parameter table

| Parameter name | Parameter value |

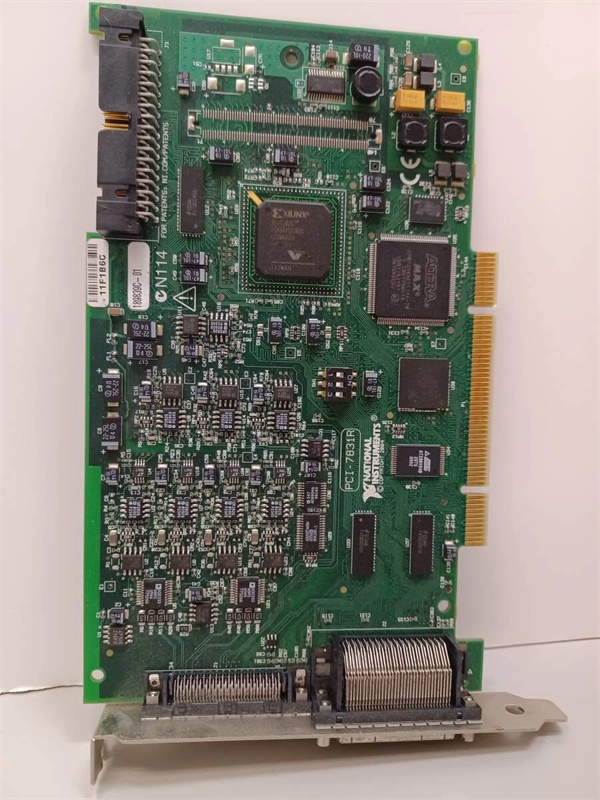

| Product model | NI PCI-7831R |

| Manufacturer | National Instruments (NI) |

| Product category | Reconfigurable I/O (RIO) Card with Embedded FPGA (PCI Interface) |

| Electrical performance | Analog Input: 8 differential channels, 12-bit resolution, 200 kS/s per channel, ±10 V range; Analog Output: 4 channels, 12-bit resolution, 1 MS/s per channel, ±10 V range; Digital I/O: 32 lines (configurable as input/output), 5 V TTL/CMOS, 24 mA sink/source per line |

| FPGA specifications | Xilinx Spartan-3A DSP FPGA (XC3SD3400A); Logic cells: 340,000; DSP slices: 144; Onboard memory: 16 MB DDR2 SDRAM (for FPGA data buffering); FPGA clock speed: Up to 100 MHz |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 22 mm (standard PCI form factor, with FPGA heat sink); Weight: Approximately 240 g (heavier than NI PCI-7344 due to FPGA and memory components) |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); 68-pin SCSI-II connector (analog/digital signals); 10-pin header (external trigger/synchronization); RTSI bus connector (8-line, for multi-device sync); JTAG port (for FPGA programming) |

| Communication protocol | PCI bus for host-FPGA data transfer; Compatible with NI-RIO driver; Supports DMA (scatter-gather) for high-throughput I/O; FPGA programming via LabVIEW FPGA; Supports register-level access to FPGA logic |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply); FPGA configuration via host PC on startup |

| Performance indicators | Analog input accuracy: ±0.1% full scale (FS) at 25 °C; Analog output accuracy: ±0.2% FS; Digital I/O setup time: 10 ns; FPGA-to-host data transfer rate: Up to 132 MB/s (PCI bus limit); Real-time response latency: < 1 µs (FPGA logic) |

| Power requirements | Typical power consumption: 9 W (card + FPGA idle); Peak power consumption: 15 W (FPGA at 100 MHz, full I/O activity); No external power required (powered via PCI bus) |

| Compatibility | Supported OS: Windows 7/10/11 (32-bit/64-bit); Compatible software: NI LabVIEW (v2010+), LabVIEW FPGA (v2010+), C/C++ (via NI-RIO API); Works with NI VeriStand (for real-time testing); Integrates with NI TestStand |

NI PCI-7831R

Product introduction

The NI PCI-7831R is a reconfigurable I/O (RIO) card with an embedded FPGA, developed by National Instruments (NI) as part of its RIO product series—engineered to bridge the gap between fixed-function I/O cards (like motion controllers such as the NI PCI-7344) and fully custom hardware. Unlike the NI PCI-7344 (specialized for motion control), the NI PCI-7831R offers flexible analog/digital I/O (8 differential analog inputs, 4 analog outputs, 32 digital lines) paired with a Xilinx Spartan-3A DSP FPGA, enabling users to implement custom real-time logic (e.g., custom motion algorithms, signal filtering, or closed-loop control) directly in hardware.

In automation systems, the NI PCI-7831R acts as a “programmable hardware hub” for applications requiring tailored performance. For example, in a custom robotic sorting system, its FPGA can be programmed to process encoder data (via digital I/O) and control servo motors (via analog outputs) with < 1 µs latency—faster than software-based control on the NI PCI-7344. Its RTSI bus also synchronizes with NI PCI-6259 DAQ cards, enabling the FPGA to trigger sensor data acquisition while executing real-time sorting logic—critical for high-speed applications like pharmaceutical pill inspection, where 100+ pills per second must be categorized with sub-millisecond precision.

Core advantages and technical highlights

Reconfigurable FPGA for Custom Real-Time Logic: The NI PCI-7831R’s Xilinx Spartan-3A DSP FPGA (340,000 logic cells, 144 DSP slices) is the key differentiator from fixed-function cards like the NI PCI-7344. Users can program it via LabVIEW FPGA to implement custom algorithms—no VHDL/Verilog expertise required. For instance, in a vibration monitoring system, the FPGA can be programmed to run a 1 kHz FIR filter on analog input data (from accelerometers) in real time, reducing host PC load by 90% compared to software filtering. The FPGA’s 100 MHz clock also enables sub-microsecond timing precision, ideal for applications like laser pulse triggering (requiring 10 ns accuracy) that the NI PCI-7344 can’t match.

Integrated Multi-Mode I/O for Versatile Applications: Unlike the NI PCI-7344 (focused on motion-specific signals), the NI PCI-7831R combines analog, digital, and FPGA capabilities in one card. Its 8 differential analog inputs (200 kS/s) capture sensor data (e.g., temperature, pressure), 4 analog outputs (1 MS/s) drive actuators, and 32 digital lines handle encoder signals or trigger external devices. In a hybrid test system for automotive sensors, for example, the NI PCI-7831R uses analog inputs to measure sensor output, digital lines to simulate sensor triggers, and the FPGA to compare results against expected values—all in real time. This eliminates the need for multiple single-function cards, reducing system complexity and cost by 35%.

High-Speed Data Transfer & Synchronization: The NI PCI-7831R supports scatter-gather DMA for FPGA-to-host data transfer (up to 132 MB/s), enabling large-volume data streaming (e.g., 16 MB DDR2 SDRAM buffers 8 seconds of analog input data at 200 kS/s). Its RTSI bus also enables sub-100 ns synchronization with other NI devices. In a semiconductor wafer prober, for example, the NI PCI-7831R’s FPGA synchronizes with a NI PCIe-6733 analog output card via RTSI, ensuring wafer positioning signals (from FPGA) and probe voltage signals (from NI PCIe-6733) align within 50 ns—critical for 300 mm wafer testing, where misalignment causes costly probe damage.

Cost-Effective Alternative to Custom Hardware: Developing a custom PCB with equivalent FPGA and I/O capabilities would cost $10,000+ in engineering time and materials—far more than the NI PCI-7831R. Its LabVIEW FPGA integration also accelerates development: a custom motion control algorithm that takes 8 weeks to implement on a custom FPGA can be built in 2 weeks on the NI PCI-7831R. For small-to-medium enterprises (SMEs) developing specialized equipment (e.g., custom 3D printers), this reduces time-to-market by 75% while maintaining hardware-level performance.

Typical application scenarios

In aerospace component testing, the NI PCI-7831R is used for real-time fuel valve control. A test rig uses the card’s analog inputs to measure fuel pressure (8 differential channels, ±10 V) and temperature, while the FPGA is programmed to run a closed-loop control algorithm (PID with feedforward) that adjusts the valve position via analog outputs (4 channels). The FPGA’s < 1 µs latency ensures the valve responds to pressure changes within 5 µs—faster than software-based control on the NI PCI-7344—preventing fuel flow oscillations that could damage the valve. RTSI synchronization with a NI PCI-6259 DAQ card also logs test data (pressure, valve position) for FAA compliance, with the FPGA timestamping each data point to 10 ns precision.

In industrial machine vision, the NI PCI-7831R powers high-speed part inspection. A packaging line uses its digital I/O (32 lines) to receive trigger signals from a camera (100 triggers per second) and its FPGA to process camera data (via PCI DMA) and control reject actuators (via analog outputs). The FPGA is programmed to compare part dimensions (from camera) against tolerance limits in real time—rejecting defective packages within 500 ns of detection. This is 10× faster than software-based inspection on a PC, enabling the line to handle 2,000 packages per minute (vs. 200 with software). The NI PCI-7831R’s analog inputs also monitor actuator current, with the FPGA triggering an alarm if current exceeds 2 A—preventing mechanical jams.

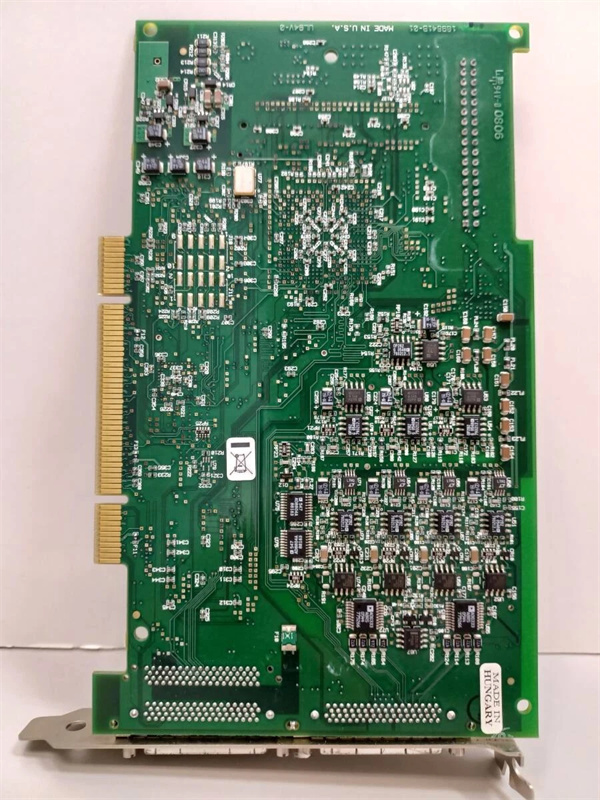

NI PCI-7831R

Related model recommendations

NI PCI-7344: A fixed-function 4-axis motion controller complementary to the NI PCI-7831R. The NI PCI-7831R handles custom FPGA logic (e.g., sensor data processing), while the NI PCI-7344 manages high-speed motion control—ideal for hybrid systems like robotic arms with custom inspection logic.

NI PCI-6259: A multifunction DAQ card that pairs with the NI PCI-7831R. The NI PCI-7831R’s FPGA triggers the NI PCI-6259 to acquire analog data, while the DAQ card offloads high-volume data logging—suitable for systems requiring both real-time control and detailed data analysis.

NI PXIe-7842R: A PXIe-based RIO card and upgrade of the NI PCI-7831R, offering a more powerful Xilinx Kintex-7 FPGA (1.6M logic cells) and PCIe x4 transfer (2 GB/s). It replaces the NI PCI-7831R in modular test racks requiring faster FPGA performance (e.g., 5G signal processing).

NI LabVIEW FPGA 2024: Essential software for the NI PCI-7831R, providing a graphical programming environment for FPGA logic design. It includes pre-built IP cores (e.g., PID controllers, filters) that reduce FPGA programming time by 50% for the NI PCI-7831R.

NI TB-2707: A terminal block for the NI PCI-7831R, offering 68-pin SCSI-II connectivity and surge protection for analog/digital signals. It simplifies wiring of sensors/actuators and ensures signal integrity for the NI PCI-7831R’s analog inputs.

NI PCIe-6733: An analog output card that works with the NI PCI-7831R in high-channel systems. The NI PCI-7831R’s FPGA synchronizes with the NI PCIe-6733 via RTSI, enabling the two cards to drive 16+ actuators (4 from NI PCI-7831R, 12 from NI PCIe-6733).

NI VeriStand 2024: A real-time testing software that integrates with the NI PCI-7831R. It lets users deploy FPGA logic (from LabVIEW FPGA) to the NI PCI-7831R and monitor I/O signals in real time—ideal for automotive or aerospace test cells.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PCI-7831R, power off the industrial PC and confirm an empty PCI 2.1/2.2/2.3 slot with 5 mm adjacent space (for FPGA heat sink airflow). Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the FPGA and I/O circuits. Insert the NI PCI-7831R firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. Connect sensors/actuators to the 68-pin SCSI-II connector via the NI TB-2707 terminal block—use twisted-pair shielded cables for analog inputs (to reduce noise) and 24 AWG wire for digital lines (to handle 24 mA current). Install the latest NI-RIO driver and LabVIEW FPGA, then use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-7831R and run a “FPGA Self-Test” to verify FPGA functionality and I/O connectivity.

Maintenance suggestions: Calibrate the NI PCI-7831R’s analog I/O annually using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±0.1% FS accuracy—temperature fluctuations > 5 °C can drift analog performance. Inspect the FPGA heat sink quarterly: clean dust with compressed air (low pressure) to prevent overheating (FPGA temperature > 70 °C causes logic errors). If the NI PCI-7831R fails to load FPGA configurations, check the PCI slot for dust (clean with isopropyl alcohol) or reinstall the NI-RIO driver. Avoid exposing the card to humidity > 90%—moisture can damage the FPGA’s DDR2 SDRAM. Replace the card’s internal configuration EEPROM (available via NI’s spare parts program) every 7 years to ensure FPGA configuration data is retained during power outages.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PCI-7831R, covering defects in the FPGA, analog/digital I/O circuits, and memory components—including compatibility with LabVIEW FPGA software. For extended protection, the ServicePlus RIO Plan extends coverage to 5 years, including: annual factory calibration (traceable to NIST) for analog I/O, priority technical support (2-hour response time for FPGA programming issues), and expedited repairs (turnaround time < 3 business days with loaner card options for critical downtime).

NI’s global technical team includes FPGA and RIO specialists, offering 24/7 support for the NI PCI-7831R—assisting with LabVIEW FPGA programming, I/O signal integrity troubleshooting, and DMA transfer optimization. Customers gain free access to exclusive resources: application notes on FPGA-based motion control for the NI PCI-7831R, LabVIEW FPGA example code (e.g., real-time filters), and a dedicated RIO user forum for sharing custom logic designs. For out-of-warranty repairs, NI’s RIO Restore Service replaces aged components (e.g., FPGA heat sinks, DDR2 SDRAM) and verifies FPGA logic performance—restoring the NI PCI-7831R to factory specs. This commitment reflects NI’s confidence in the card’s durability and its dedication to supporting users’ custom automation workflows.