Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

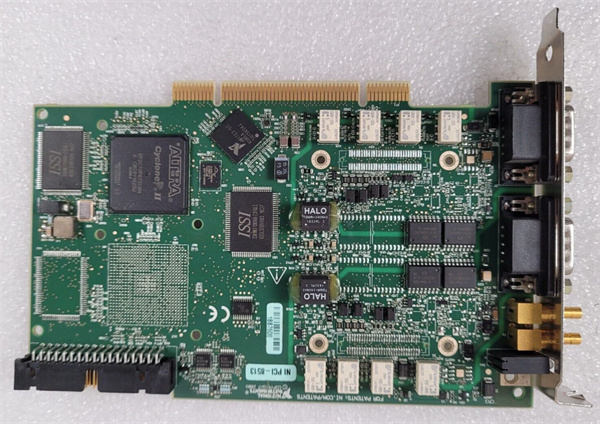

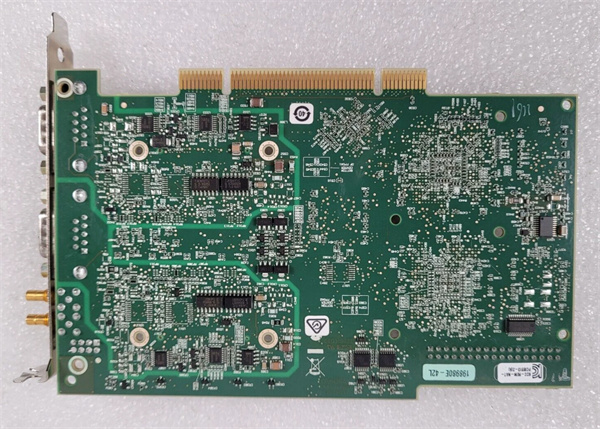

| Product model | NI PCI-8513 |

| Manufacturer | National Instruments (NI) |

| Product category | PCIe-Based Dual-Port CAN Interface Card (High-Speed Industrial Communication) |

| CAN protocols supported | CAN 2.0A (11-bit ID), CAN 2.0B (29-bit ID); supports CAN FD (Flexible Data Rate) |

| CAN FD data rates | Up to 8 Mbps (data phase); 1 Mbps (arbitration phase) |

| Standard CAN data rates | Up to 1 Mbps |

| Number of CAN ports | 2 independent, isolated ports |

| Isolation voltage | 250 Vrms (port-to-port and port-to-ground) |

| Communication interface | PCI Express (PCIe) x1; compatible with PCIe Gen 1/2/3 slots (backward compatible) |

| Data transfer rate (PCIe) | Up to 2.5 Gbps (PCIe Gen 1 x1); supports burst data transfer for high-throughput scenarios |

| Message buffer | 8,192 receive/transmit buffers per port (for extended burst data handling) |

| Triggering capabilities | Hardware-based CAN message triggering (by ID, data content, timestamp); multi-port trigger synchronization |

| Synchronization support | External trigger input/output; supports multi-card synchronization via PXI Trigger Bus (with adapter) |

| Operating temperature range | 0 °C to 55 °C (32 °F to 131 °F) |

| Storage temperature range | -20 °C to 70 °C (-4 °F to 158 °F) |

| Power consumption | +5 VDC @ 1.2 A (max); +12 VDC @ 0.4 A (max); -12 VDC @ 0.06 A (max) |

| Compliance standards | CE, FCC Class A, UL 61010-1, IEC 61010-1, ISO 11898-2 (CAN physical layer), RoHS 3 |

| Software compatibility | NI-CAN driver, LabVIEW, LabWindows/CVI, C/C++, .NET, Python (via NI-CAN API) |

| Connector type | DSUB-9 (per CAN port, compatible with standard CAN bus cabling) |

NI PCI-8513

Product Introduction

The NI PCI-8513 is a high-performance PCI Express (PCIe) dual-port CAN interface card from National Instruments (NI), engineered to elevate industrial communication beyond the capabilities of the PCI-based NI PCI-8511. As a next-generation model in NI’s CAN portfolio, the NI PCI-8513 retains the dual-port flexibility and CAN FD support of its predecessor while upgrading to a PCIe x1 interface—delivering faster data transfer, larger message buffers, and better scalability for high-throughput applications.

Designed for modern industrial automation, automotive production testing, and aerospace ground systems, the NI PCI-8513 addresses the limitations of legacy PCI buses: its PCIe interface eliminates data bottlenecks, enabling seamless transfer of large CAN FD datasets (e.g., 8 Mbps sensor streams) to the host PC. When paired with NI’s NI-CAN driver, the NI PCI-8513 integrates with software tools like LabVIEW to build real-time multi-network control or monitoring systems—from dual-ECU automotive testing to factory-wide CAN network management. This combination of PCIe speed, dual-port isolation, and industrial-grade reliability makes the NI PCI-8513 a trusted choice for teams needing to future-proof their CAN communication infrastructure.

Core Advantages and Technical Highlights

PCIe x1 Interface for Faster Data Transfer: The NI PCI-8513’s PCIe x1 interface is a transformative upgrade over the NI PCI-8511’s 33 MHz PCI bus, delivering up to 2.5 Gbps data transfer rate—10x faster than PCI. This eliminates bottlenecks in high-throughput scenarios, such as automotive production lines where the NI PCI-8513 simultaneously captures CAN FD data (8 Mbps) from two ECUs. For example, a car manufacturer uses the NI PCI-8513 to log 10 minutes of dual-port CAN FD data (≈1.2 GB total) to a PC—its PCIe interface transfers this data without latency, whereas the NI PCI-8511’s PCI bus might drop frames under the same load. This speed ensures no critical test data is lost, even in extended high-speed captures.

Expanded Message Buffers for Extended Burst Handling: The NI PCI-8513 doubles the NI PCI-8511’s per-port buffer capacity to 8,192 receive/transmit buffers, enabling it to handle longer burst data traffic. In aerospace avionics testing, for instance, the NI PCI-8513 captures sequential CAN messages from two separate aircraft subsystems (e.g., navigation and communication) during system startup—a period when message traffic spikes to 1,000 messages/second. The expanded buffers store these messages while the PC processes previous data, ensuring no commands or status updates are dropped. This buffer size is 8x larger than entry-level dual-port CAN cards, making the NI PCI-8513 suitable for mission-critical applications with unpredictable traffic patterns.

Dual-Port Isolation with Multi-Network Flexibility: Like the NI PCI-8511, the NI PCI-8513 features two 250 Vrms-isolated CAN ports—critical for simultaneous communication with separate networks without cross-talk. In electric vehicle (EV) battery testing, engineers use one port of the NI PCI-8513 to communicate with the Battery Management System (BMS) CAN FD network (8 Mbps) and the other port to monitor the charging control CAN network (500 kbps). The isolation protects the NI PCI-8513 and host PC from voltage transients common in EV high-voltage systems, while the dual-port design eliminates the need for two single-port cards. Unlike the NI PCI-8511, the NI PCI-8513 also supports multi-port trigger synchronization, letting users align data capture across both ports for precise time-correlated analysis.

Backward Compatibility with Legacy and Modern Systems: The NI PCI-8513 maintains compatibility with both legacy CAN (up to 1 Mbps) and modern CAN FD (up to 8 Mbps) protocols, ensuring it works with existing industrial systems while supporting future upgrades. For example, a manufacturing plant using older CAN-based motors (250 kbps) can deploy the NI PCI-8513 to monitor those motors via one port, while using the second port to connect to a new CAN FD-enabled robot (2 Mbps)—no need to replace the entire communication infrastructure. The card’s PCIe interface also works with Gen 1/2/3 slots, making it compatible with most modern industrial PCs and ensuring long-term usability.

Typical Application Scenarios

The NI PCI-8513 excels in high-throughput, multi-network CAN/CAN FD applications across industries. In automotive production testing, it is a cornerstone of dual-ECU test stations: engineers connect the NI PCI-8513 to a vehicle’s powertrain ECU (port 1, CAN FD 8 Mbps) and infotainment ECU (port 2, CAN 1 Mbps), using the card to send calibration commands and log response data. The NI PCI-8513’s PCIe interface ensures all data is transferred to the test PC in real time, while its 8,192 buffers handle burst traffic during ECU initialization. By integrating with LabVIEW, the team automates pass/fail judgments for each ECU, reducing test time by 30% compared to using the NI PCI-8511.

In factory automation, the NI PCI-8513 enables centralized monitoring of two independent CAN networks: a food processing plant uses port 1 to monitor temperature and pressure sensors on a production line (CAN 500 kbps) and port 2 to control conveyor speed and packaging equipment (CAN FD 2 Mbps). The NI PCI-8513’s isolation protects the control PC from electrical noise generated by washing equipment, while its PCIe speed ensures no sensor data is delayed—critical for maintaining food safety compliance. The card’s multi-port triggering also lets technicians capture data from both networks only when a temperature threshold is exceeded, simplifying fault diagnosis.

In aerospace ground testing, the NI PCI-8513 synchronizes communication with two avionics subsystems: technicians connect port 1 to a flight control system (CAN 1 Mbps) and port 2 to a cabin pressure control system (CAN 500 kbps), using the card’s external trigger to align data capture with other test equipment (e.g., power supplies, oscilloscopes). The NI PCI-8513’s robust design ensures reliable operation in test labs with temperature variations (0–55 °C), while its PCIe interface streams large datasets to a server for post-test analysis—meeting strict aerospace documentation requirements.

NI PCI-8513

Related Model Recommendations

NI PCI-8511: A PCI-based dual-port CAN interface card, a cost-effective alternative to the NI PCI-8513 for legacy systems where PCIe slots are unavailable (e.g., older industrial PCs).

NI PCIe-8512: A PCIe single-port CAN FD card, a complementary model to the NI PCI-8513 for setups needing one high-speed CAN network (e.g., standalone EV battery testing) alongside the NI PCI-8513’s dual networks.

NI cDAQ-9853: A CompactDAQ dual-port CAN module, a portable alternative to the NI PCI-8513 for field testing (e.g., on-site aircraft CAN diagnostics) where PCIe-based systems are impractical.

NI PXIe-8513: A PXIe-based dual-port CAN FD module, a modular alternative to the NI PCI-8513 for large-scale test systems (e.g., multi-DUT automotive production lines) requiring PXI synchronization.

NI PCI-8522: A PCI-based dual-port CAN/LIN card, an upgrade to the NI PCI-8511 (but not PCIe) for applications needing both CAN and LIN protocols (e.g., automotive body control testing).

NI PCIe-8532: A high-speed PCIe dual-port CAN FD card with 16 Mbps data rate, a faster upgrade to the NI PCI-8513 for ultra-high-throughput applications (e.g., EV fast-charging data logging).

NI PCI-6221: A multifunctional DAQ card, a complementary model to the NI PCI-8513 for setups needing CAN communication + high-precision analog measurement (e.g., CAN-based sensor control + voltage monitoring).

NI PCI-7811: A reconfigurable RIO card with FPGA-based CAN emulation, a complementary model to the NI PCI-8513 for setups needing dedicated CAN communication + custom I/O (e.g., robotic control + dual-network CAN monitoring).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the NI PCI-8513, confirm the host PC has an available PCIe slot (Gen 1/2/3 x1 or larger, as PCIe slots are backward compatible) and meets system requirements (Windows 10/11, 8 GB RAM, 300 MB free disk space for NI-CAN drivers). Power off the PC and disconnect all power sources. Use an anti-static wristband and mat to handle the NI PCI-8513—its PCIe and CAN transceiver components are sensitive to electrostatic discharge. Align the card’s PCIe connector with the slot, press firmly until the bracket seats against the case, and secure with a screw. Connect CAN bus cabling to the DSUB-9 ports (ensure 120 Ω termination resistors at each bus endpoint). After installation, install the latest NI-CAN driver, then run the “NI CAN Configuration Utility” to verify port functionality, set CAN FD/data rates, and enable multi-port synchronization if needed.

Maintenance suggestions: Clean the NI PCI-8513’s PCIe connector every 2 months with low-pressure, oil-free compressed air to remove dust—PCIe pins are denser than PCI and more prone to connectivity issues from debris. Inspect CAN cable connections quarterly: tighten loose screws and replace damaged cables to avoid signal loss, especially in high-vibration environments. If the NI PCI-8513 exhibits data drops, check for PCIe slot compatibility (ensure the slot is Gen 1 or newer), verify CAN bus termination, and use the NI-CAN utility to run a self-test. Back up CAN configuration settings (baud rate, filter rules, trigger logic) via the utility to speed up reconfiguration. For hardware issues (e.g., unresponsive port, PCIe communication errors), contact NI support—do not open the card, as this voids the warranty and risks damaging sensitive components.

Service and Guarantee Commitment

The NI PCI-8513 comes with a standard 2-year manufacturer’s warranty—longer than the NI PCI-8511’s 1-year coverage—covering defects in materials and workmanship. NI guarantees the NI PCI-8513 will meet all published technical specifications during the warranty period, with free expedited repair (24–48 hour turnaround for industrial customers) or replacement of defective units. Customers can extend coverage to 5 years via NI’s Extended Service Program (ESP), which includes annual calibration (traceable to ISO 17025), priority technical support for PCIe/CAN FD integration, and on-site troubleshooting for complex multi-network setups.

NI provides specialized support for the NI PCI-8513 through its CAN and PCIe expert team: users gain access to exclusive resources, such as application notes titled “Optimizing PCIe Data Throughput for Dual-Port CAN FD with the NI PCI-8513” and video tutorials on multi-port trigger setup. For custom projects (e.g., building a automotive production test system), NI offers professional services—including driver integration, LabVIEW code development for real-time data logging, and on-site training—to help users maximize the NI PCI-8513’s performance. This commitment ensures users future-proof their CAN communication infrastructure and protect their investment in high-throughput industrial technology.