Description

Detailed parameter table

| Parameter name | Parameter value |

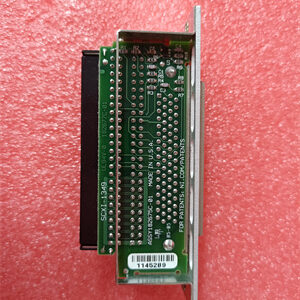

| Product model | NI PCIE-6612 |

| Manufacturer | National Instruments (NI) |

| Product category | C Series Timing and Synchronization Module |

| Clock Output Channels | 8 isolated differential clock outputs |

| Trigger I/O Channels | 4 isolated differential trigger inputs, 4 isolated differential trigger outputs |

| Clock Frequency Range | 10 Hz to 100 MHz (stable, low-jitter) |

| Timebase Stability | ±50 ppm (typical) at 25 °C; ±100 ppm (maximum) over operating temperature |

| Isolation Voltage | 2,500 Vrms (channel-to-channel, channel-to-chassis) |

| Operating Temperature Range | -40 °C to 70 °C (extended industrial range) |

| Storage Temperature Range | -40 °C to 85 °C |

| Connector Type | 2× 15-pin D-sub female connectors (for clock/trigger I/O) |

| Power Consumption | 1.2 W (typical, from C Series chassis backplane) |

| Weight | 6.2 oz (176 g) |

| Chassis Compatibility | NI CompactRIO (cRIO), CompactDAQ (cDAQ) chassis with C Series slots |

NI PCIE-6612

Product introduction

The National Instruments NI PCIE-6612 is a high-performance C Series timing and synchronization module, engineered to solve critical clock and trigger coordination challenges in industrial automation, test, and measurement systems. As a key member of NI’s timing module lineup, it delivers precise, isolated timing signals to unify operations across multiple devices—eliminating timing skew that can compromise data accuracy or system efficiency.

Designed for integration with NI’s CompactRIO and CompactDAQ chassis, the NI PCIE-6612 acts as a central timing hub for complex setups. It generates up to 8 stable differential clock signals (10 Hz to 100 MHz) and routes 4 differential trigger inputs/outputs, ensuring synchronized operation between sensors, data acquisition (DAQ) modules, and actuators. When paired with NI’s LabVIEW software or NI-DAQmx driver, the NI PCIE-6612 enables intuitive configuration of timing profiles, making it easy to adapt to changing application needs without hardware rework.

Core advantages and technical highlights

High-Isolation Design for Industrial Reliability

The NI PCIE-6612 features 2,500 Vrms isolation between channels and from channels to chassis, a critical advantage for harsh industrial environments. This isolation protects the module and connected devices from electrical noise, ground loops, and voltage transients—common issues in manufacturing floors or power-generation facilities. Unlike non-isolated timing modules, the NI PCIE-6612 maintains signal integrity even in high-interference settings, reducing downtime and data errors.

Low-Jitter Clock Signals for Precision

With a clock frequency range of 10 Hz to 100 MHz and typical timebase stability of ±50 ppm, the NI PCIE-6612 delivers ultra-low-jitter timing signals. Low jitter (less than 1 ns peak-to-peak at 100 MHz) ensures consistent synchronization across connected devices, which is essential for applications like high-speed data logging, automated test equipment (ATE), or motion control. For example, in a semiconductor test setup, the NI PCIE-6612’s precise clocks ensure that test measurements align with device operation, improving test accuracy and repeatability.

Flexible I/O Configuration for Scalability

The NI PCIE-6612 offers 8 clock outputs and 8 total trigger I/O (4 in, 4 out), all differential to minimize noise pickup. This flexibility allows the module to support both small-scale setups (e.g., synchronizing 2 DAQ modules) and large systems (e.g., coordinating 8 sensors and 4 actuators). The differential signaling also extends signal transmission distances—up to 10 meters for clock signals—without degradation, making the NI PCIE-6612 suitable for distributed systems where devices are spread across a facility.

Typical application scenarios

In industrial automation, the NI PCIE-6612 is a cornerstone for synchronized motion control. For example, in an automotive assembly line, it synchronizes the timing of robotic arms, conveyor belt motors, and vision inspection cameras. The module’s 8 clock outputs ensure each robot moves in precise sequence, while trigger inputs capture vision data at the exact moment a part is in position—reducing assembly errors and increasing throughput. The NI PCIE-6612’s isolation also protects against electrical noise from welding equipment or motor drives nearby.

In energy sector applications, such as wind turbine condition monitoring, the NI PCIE-6612 synchronizes data acquisition from vibration sensors, temperature probes, and power meters. Its stable clocks ensure that sensor readings are time-stamped consistently, allowing engineers to correlate vibrations with power output fluctuations accurately. The module’s extended temperature range (-40 °C to 70 °C) also makes it suitable for installation in turbine nacelles, where temperatures vary widely.

In aerospace and defense, the NI PCIE-6612 supports ATE systems for avionics testing. It synchronizes the timing of signal generators, oscilloscopes, and DAQ modules to simulate real-world flight conditions, ensuring that avionics components (e.g., navigation systems) are tested under accurate timing constraints. The NI PCIE-6612’s low jitter and isolation also meet the strict reliability requirements of defense applications, where system failure is not an option.

NI PCIE-6612

Related model recommendations

NI PCIE-6611: A sibling module in the same timing series as the NI PCIE-6612, with 4 clock outputs (instead of 8) and 4 trigger I/O. It’s ideal for smaller systems where fewer timing signals are needed, offering a cost-effective alternative to the NI PCIE-6612 while maintaining isolation and low jitter.

NI 9469: A C Series digital I/O module that pairs with the NI PCIE-6612 for expanded digital control. While the NI PCIE-6612 handles timing, the NI 9469 adds 32 channels of digital I/O, enabling synchronized control of relays, LEDs, or other digital devices in the same system.

NI PCIE-6289: A high-speed analog input module compatible with the NI PCIE-6612. The NI PCIE-6612 synchronizes the NI PCIE-6289’s data acquisition, ensuring that analog signals (e.g., voltage, current) are sampled at precise intervals—critical for applications like waveform analysis.

NI cRIO-9039: A CompactRIO chassis designed to host the NI PCIE-6612. This chassis provides ruggedization (IP65 rating optional) and additional slots for other C Series modules, making it a complete solution for industrial-grade synchronized systems.

NI 9514: A servo drive module that works with the NI PCIE-6612 in motion control setups. The NI PCIE-6612 supplies timing signals to the NI 9514, ensuring that servo motors operate in sync with other system components (e.g., vision cameras).

NI PCIE-6674T: An upgraded timing module with higher performance than the NI PCIE-6612, including 10 MHz to 1 GHz clock range and GPS synchronization. It’s recommended for applications requiring ultra-high precision (e.g., satellite testing) where the NI PCIE-6612’s 100 MHz max clock is insufficient.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCIE-6612, verify that the target C Series chassis (e.g., NI cRIO-9030) has an available slot and meets the module’s power requirements (1.2 W from the backplane). Ensure the installation environment is free from excessive dust, moisture, or corrosive gases, and that the temperature stays within -40 °C to 70 °C. Tools needed include a Phillips-head screwdriver (for securing the module to the chassis) and shielded twisted-pair (STP) cables (24 AWG or larger) for connecting clock/trigger signals. Always power off the chassis before inserting the NI PCIE-6612 to prevent damage to the module or backplane.

Maintenance suggestions

For daily maintenance of the NI PCIE-6612, inspect the D-sub connectors monthly for corrosion or loose pins—clean connectors with a dry, lint-free cloth if needed. Monitor the module’s status LEDs (power, fault) via the chassis interface; a solid red fault LED indicates issues like overvoltage or loss of isolation, which require referencing the user manual for troubleshooting. Every 6 months, update the module’s firmware using NI Measurement & Automation Explorer (MAX) to access the latest stability improvements. When replacing cables, use only shielded differential cables to maintain signal integrity, and avoid mixing the NI PCIE-6612’s isolated channels with non-isolated devices to prevent ground loops.

Service and guarantee commitment

National Instruments (NI) backs the NI PCIE-6612 with a 2-year standard warranty, covering defects in materials and workmanship. If the NI PCIE-6612 fails under normal use, NI provides free repair or replacement, with expedited service options available for critical applications. NI’s global technical support team is accessible 24/7 via email, phone, and online chat, offering assistance with installation, configuration (e.g., LabVIEW integration), and troubleshooting. Additionally, NI provides lifetime access to firmware updates and driver downloads for the NI PCIE-6612, ensuring the module remains compatible with new NI hardware and software. This commitment reflects NI’s confidence in the NI PCIE-6612’s reliability and ensures customers maximize their investment over the module’s long operational lifespan.

If you need to adjust specific sections—such as adding more application details for a particular industry (e.g., medical device testing) or refining technical parameters based on your project’s needs—feel free to share further requirements. I can also expand on related models or maintenance procedures to better align with your target audience.