Description

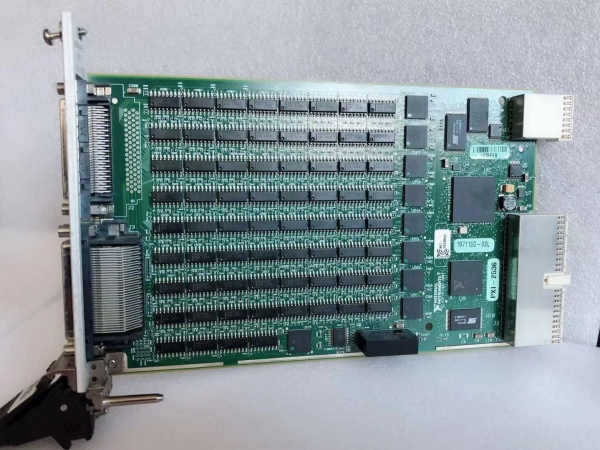

NI PXI-2536

- •

Model Number: PXI-2536 - •

Manufacturer: National Instruments - •

Product Type: PXI Matrix Switch Module - •

Matrix Configuration: 64×32 cross-point matrix (4-wire) - •

Number of Crosspoints: 2,048 (512 4-wire paths) - •

Switching Type: 4-wire (Kelvin) multiplexing - •

Maximum Voltage: 300V channel-to-channel - •

Carry Current: 1A maximum per channel - •

Switching Speed: 10ms typical (including settle time) - •

Contact Life: 1 million operations minimum - •

Contact Resistance: <2Ω typical - •

Off-Isolation: >90dB at 1MHz - •

Bandwidth: DC to 100MHz - •

Relay Type: Electromechanical relays - •

Kelvin Connection: Independent force and sense lines - •

Control Interface: PXI trigger lines - •

Operating Temperature: 0°C to 55°C - •

Power Consumption: 6W typical NI PXI-2536