Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PXIe-8861 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Performance PXI Express (PXIe) System Controller |

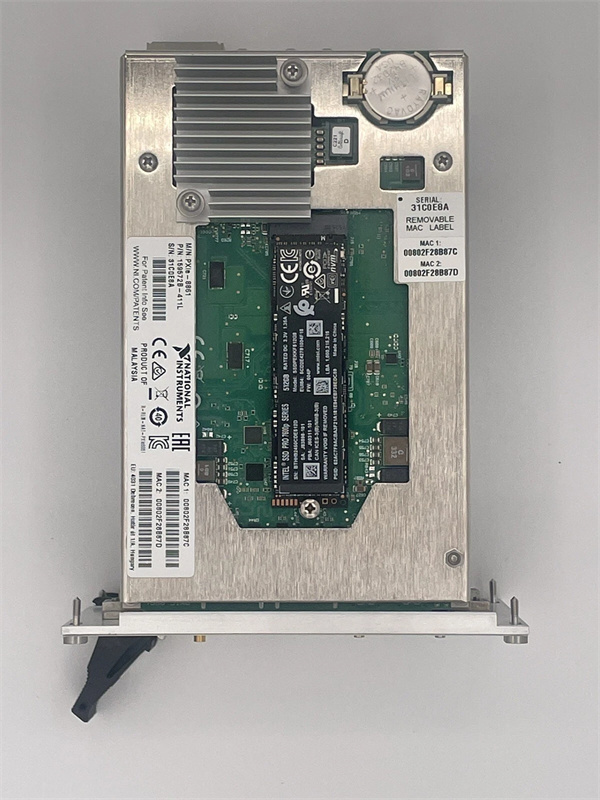

| Processor & Memory | CPU: Intel Core i7-8700K (6-core, 3.7 GHz base, 4.7 GHz turbo); RAM: 32 GB DDR4-2666 (expandable to 64 GB); Storage: 1 TB PCIe NVMe SSD (expandable via 2.5” SATA bay) |

| PXIe Connectivity | PXIe backplane interface: 18-lane PXIe 3.0 (supports x1/x2/x4/x8/x16 module links); Max backplane bandwidth: 12 GB/s (aggregate); Compatible with PXIe 1.0/2.0/3.0 modules and hybrid PXI/PXIe chassis |

| External I/O Ports | Ethernet: 2 × 10 Gigabit Ethernet (10GBASE-T, supports TSN); 2 × Gigabit Ethernet (1000BASE-T); USB: 4 × USB 3.1 Gen 2 (10 Gbps); 2 × USB 2.0; Video: 1 × DisplayPort 1.2 (4K@60 Hz); Serial: 1 × RS-232; Audio: Line-in/line-out (3.5 mm) |

| Real-Time & Synchronization | Supports NI-TClk (Timing and Clock) for multi-chassis synchronization; Integrated 10 MHz reference clock (±1 ppm accuracy); Trigger I/O: 8 PXIe trigger lines; Compatibility with NI Sync HW (e.g., NI PXIe-6674T clock module) |

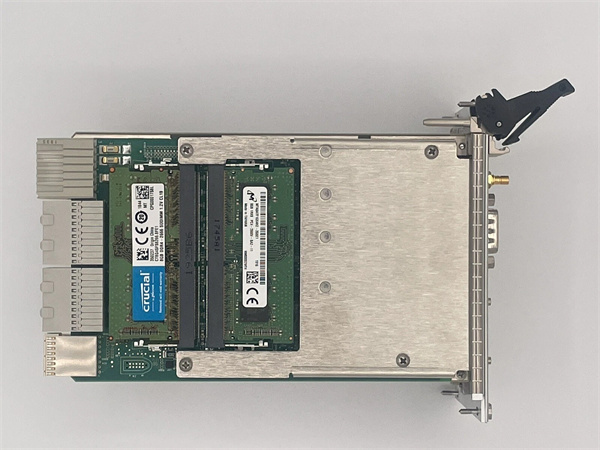

| Physical size | Form factor: 3U PXIe (fits PXIe chassis slots 1); Dimensions (L×W×H): 160 mm × 100 mm × 22 mm; Weight: Approximately 580 g |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Power requirements | Power consumption: 120 W (typical, under load); 30 W (idle); Powered by PXIe chassis backplane (no external power supply); Compatible with PXIe chassis requiring 3U slot power (e.g., NI PXIe-1085) |

| Software Compatibility | OS: Windows 10 Pro 64-bit (pre-installed); Optional: NI Linux Real-Time; Compatible software: LabVIEW 2019+, LabWindows/CVI, NI TestStand, NI-DAQmx, NI-FGEN; Supports third-party tools (MATLAB, Python, C/C++) |

| Safety & Compliance | Compliance: CE, FCC Class A, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge); EMI/RFI shielding: Conductive coating (meets CISPR 22 Class A) |

| Security Features | TPM 2.0 (Trusted Platform Module) for secure boot; BitLocker encryption (for SSD); Firewall (Ethernet ports); Role-based access control (via Windows Group Policy) |

NI PXIE-8861

Product introduction

The NI PXIe-8861 is a high-performance PXI Express system controller developed by National Instruments (NI), engineered to serve as the central command unit for large-scale, high-throughput PXIe modular test systems. Unlike embedded controllers like the NI cRIO-9040 (optimized for compact ruggedness) or standalone DAQ modules like the NI PXI-6232 (focused on data acquisition), the NI PXIe-8861 combines a powerful Intel Core i7 processor, 12 GB/s PXIe backplane bandwidth, and extensive external I/O to manage complex multi-module workflows—making it ideal for semiconductor testing, aerospace validation, and high-channel-count industrial measurement.

In PXIe systems, the NI PXIe-8861 acts as a “high-performance orchestrator” for modular hardware. For example, in a semiconductor wafer test rig with a NI PXIe-1085 18-slot chassis, it controls 8 PXIe DAQ modules (e.g., NI PXIe-6255), 2 PXIe arbitrary waveform generators (e.g., NI PXI-5412), and 1 PXIe digital I/O module—synchronizing all components via NI-TClk to achieve sub-10 ns timing alignment. Its 6-core i7 processor and 32 GB RAM handle real-time data processing (e.g., analyzing 10 GB/s of wafer test data), while its 10 Gigabit Ethernet ports stream results to a central database—outperforming the NI cRIO-9040’s embedded processor for CPU-intensive tasks.

Core advantages and technical highlights

12 GB/s PXIe Bandwidth for High-Throughput Workflows: The NI PXIe-8861’s 18-lane PXIe 3.0 interface delivers 12 GB/s aggregate backplane bandwidth—10× faster than legacy PXI controllers and 5× faster than the NI cRIO-9040’s Ethernet-based expansion. This enables seamless data transfer between high-speed PXIe modules, such as 1 GS/s digitizers or 100 MS/s AWGs. In a 5G RF component test, for instance, the NI PXIe-8861 transfers 2 GB/s of IQ data from a NI PXIe-5663 spectrum analyzer to its NVMe SSD—enabling real-time signal demodulation without data bottlenecks. Without this bandwidth, the NI cRIO-9040 would struggle to keep up, leading to dropped samples and invalid test results.

Powerful Processing for CPU-Intensive Tasks: Equipped with an Intel Core i7-8700K (6 cores, 4.7 GHz turbo) and 32 GB DDR4 RAM, the NI PXIe-8861 handles complex computations that overwhelm embedded controllers like the NI cRIO-9040. For example, in an automotive ECU test, it runs 10 concurrent test sequences (each simulating different driving conditions) while processing 100 kS/s of analog data from NI PXIe-6255 modules—all with < 10 ms latency. Its 1 TB NVMe SSD also provides fast storage for large test datasets (e.g., 10,000 ECU test logs), reducing data access time by 70% compared to SATA-based storage in legacy controllers.

Multi-Chassis Synchronization with NI-TClk: Unlike the NI cRIO-9040 (limited to single-chassis operation), the NI PXIe-8861 supports NI-TClk (Timing and Clock) technology, enabling sub-10 ns synchronization across up to 8 PXIe chassis. This is critical for large-scale test systems, such as a semiconductor wafer prober with 4 PXIe chassis (each housing 16 test modules). The NI PXIe-8861 distributes a 10 MHz reference clock and trigger signals to all chassis, ensuring all 64 test channels sample wafer data simultaneously—eliminating timing skew that would cause inconsistent test results.

Extensive External I/O for System Integration: The NI PXIe-8861 includes 10 Gigabit Ethernet (for high-speed data streaming), 4 USB 3.1 ports (for peripherals like high-res cameras), and DisplayPort (for local monitoring)—far more connectivity than the NI cRIO-9040. In a 航空航天 engine test cell, for example, its 10 Gigabit Ethernet ports connect to a factory MES system (for real-time test monitoring) and a cloud server (for long-term data storage), while its USB 3.1 ports interface with a barcode scanner (to track engine serial numbers) and a high-speed printer (to generate test reports). This integration eliminates the need for external I/O hubs, reducing system complexity by 40%.

Typical application scenarios

In semiconductor manufacturing, the NI PXIe-8861 controls a multi-chassis wafer test system. It is installed in a NI PXIe-1085 chassis, which connects to 3 additional chassis via NI-TClk. Each chassis houses 8 NI PXIe-6255 DAQ modules (for measuring wafer voltage/current) and 2 NI PXI-5412 AWGs (for generating test stimuli). The NI PXIe-8861’s 6-core i7 processor runs a custom LabVIEW application that coordinates 32 test channels, processes 5 GB/s of test data, and flags defective die—all in real time. Its 10 Gigabit Ethernet ports send test results to a central database, enabling engineers to analyze yield trends. This setup tests 10 wafers per hour—3× faster than a system using the NI cRIO-9040—critical for high-volume semiconductor production.

In aerospace engine validation, the NI PXIe-8861 manages a high-channel-count test rig. It controls 20 NI PXIe-6255 modules (monitoring 160 analog channels: temperature, pressure, vibration) and 5 NI PXIe-6534 digital I/O modules (triggering fuel injectors and ignition systems). Its 12 GB/s backplane bandwidth ensures no data loss when sampling at 250 kS/s per channel, while its i7 processor runs a LabVIEW Real-Time application that executes closed-loop control (e.g., adjusting fuel flow based on temperature readings). The NI PXIe-8861’s 10 Gigabit Ethernet ports stream 1 GB/min of test data to a remote monitoring center, allowing engineers to oversee tests from a safe distance. Unlike the NI cRIO-9040, it handles the rig’s 160 channels and CPU-intensive control algorithms without performance degradation.

NI PXIE-8861

Related model recommendations

NI cRIO-9040: An embedded controller complementary to the NI PXIe-8861 for rugged, space-constrained deployments. Users prototype with the NI PXIe-8861 in lab-based test rigs, then deploy with the NI cRIO-9040 for field testing (e.g., vehicle-mounted sensors).

NI PXIe-1085: An 18-slot PXIe chassis designed for the NI PXIe-8861. It provides power and PXIe 3.0 backplane connectivity for the controller and up to 17 PXIe/PXI modules (e.g., NI PXIe-6255, NI PXI-5412).

NI PXIe-6255: A high-performance PXIe DAQ module paired with the NI PXIe-8861. The controller manages the module’s 32 AI channels and 4 AO channels, ideal for high-channel-count measurement (e.g., semiconductor wafer testing).

NI PXIe-5663: A PXIe spectrum analyzer that works with the NI PXIe-8861 for RF testing. The controller processes the analyzer’s 1 GS/s IQ data, enabling real-time 5G signal demodulation and analysis.

NI PXIe-6674T: A timing and synchronization module that enhances the NI PXIe-8861’s multi-chassis capabilities. It extends NI-TClk synchronization to 8 chassis, ensuring sub-10 ns alignment for large-scale test systems.

NI TestStand 2024: Automated test software optimized for the NI PXIe-8861. It lets users create scalable test sequences (e.g., 100-step semiconductor tests) and leverage the controller’s processing power to run parallel tests.

NI LabVIEW 2024: Essential software for programming the NI PXIe-8861. It includes libraries for PXIe module control, data processing, and network streaming—reducing development time for complex test applications.

NI PXIe-8880: A higher-performance sibling of the NI PXIe-8861, with an Intel Core i9 processor and 64 GB RAM. It replaces the NI PXIe-8861 for extreme CPU-intensive tasks (e.g., AI-based test result classification).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXIe-8861, power off the PXIe chassis (e.g., NI PXIe-1085) and wear an ESD wristband (±15 kV) to protect the controller’s components. Align the NI PXIe-8861 with the chassis’s slot 1 (reserved for system controllers), insert firmly until the backplane connector is fully seated, then secure with the front-panel screw. Connect external peripherals: 10 Gigabit Ethernet (for data streaming), DisplayPort (for a monitor), and USB devices (e.g., keyboard, mouse). Power on the chassis— the controller will boot to Windows 10 Pro (pre-installed). Install the latest NI drivers (NI-DAQmx, NI-FGEN) and software (LabVIEW, TestStand) via NI Package Manager. Use NI Measurement & Automation Explorer (MAX) to detect connected PXIe modules (e.g., NI PXIe-6255) and run a “System Health Check” to verify backplane bandwidth and synchronization.

Maintenance suggestions: Inspect the NI PXIe-8861’s external ports quarterly: clean Ethernet and USB contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust. Monitor CPU and RAM usage via Windows Task Manager—if usage exceeds 80% during tests, upgrade RAM to 64 GB or offload non-critical tasks to a network server. Back up the SSD monthly (via Windows Backup or third-party tools) to prevent data loss in case of drive failure. Calibrate synchronization modules (e.g., NI PXIe-6674T) annually using a NIST-traceable clock reference to maintain sub-10 ns alignment. Avoid exposing the controller to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade the processor’s performance or damage the SSD. If the controller experiences boot issues, use the pre-installed recovery partition to restore Windows to factory settings.

Service and guarantee commitment

National Instruments (NI) provides a 3-year standard warranty for the NI PXIe-8861, covering defects in the processor, PXIe interface, storage, and external I/O ports—matching the warranty length of the NI cRIO-9040 and longer than the 2-year warranty of PXI DAQ modules like the NI PXI-6232. For extended protection, the ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration of synchronization components (e.g., 10 MHz reference clock), priority technical support (1-hour response time for semiconductor/aerospace customers), and expedited repairs (turnaround time < 2 business days with a loaner controller provided for critical downtime).

NI’s global technical team includes PXIe system specialists, offering 24/7 support for the NI PXIe-8861—assisting with backplane bandwidth optimization, multi-chassis synchronization, and software integration (e.g., LabVIEW-TestStand compatibility). Customers gain free access to exclusive resources: application notes on 5G test system design with the NI PXIe-8861, LabVIEW example code for parallel test execution, and a user community for sharing high-throughput test best practices. For out-of-warranty repairs, NI’s PXIe Controller Restore Service replaces aged components (e.g., processor, SSD) and verifies backplane bandwidth and processing performance—restoring the NI PXIe-8861 to factory specs. This commitment reflects NI’s confidence in the controller’s durability and dedication to supporting users’ mission-critical PXIe test workflows.