Description

NI SBRIO-9607 Product Description

Detailed parameter table

| Parameter name | Parameter value |

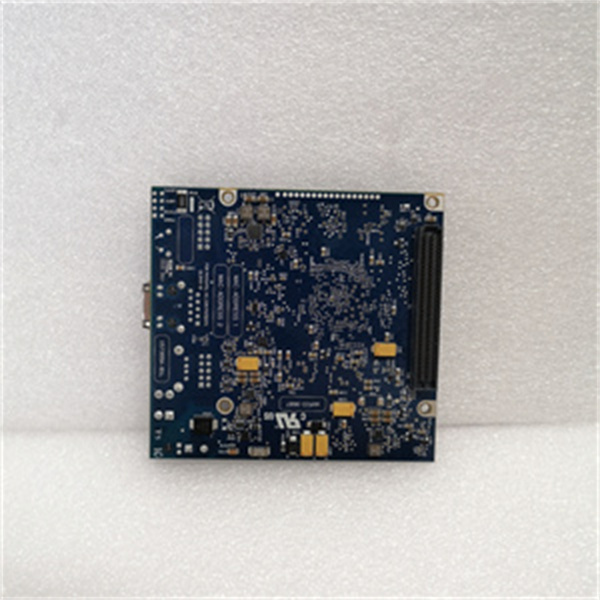

| Product model | SBRIO-9607 |

| Manufacturer | NI |

| Product category | Single-Board RIO Controller |

| Processor | ARM Cortex-A9 (Dual-core, 800 MHz) |

| FPGA | Xilinx Zynq-7020 (Artix-7 based, 85K logic cells) |

| RAM | 512 MB DDR3 |

| Storage | 4 GB eMMC flash, microSD card slot (up to 32 GB) |

| I/O Channels | 8x 16-bit analog inputs (±10 V), 2x 16-bit analog outputs (±10 V), 16x digital I/O (configurable as input/output) |

| Communication Interfaces | 2x Gigabit Ethernet, 2x USB 2.0 Host, RS-232, CAN 2.0B |

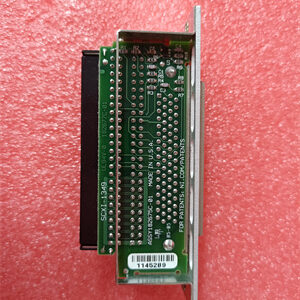

| Expansion | 1x MXM connector (for I/O expansion modules) |

| Operating System | NI Linux Real-Time |

| Real-Time Performance | Deterministic execution with µs-level jitter |

| Form Factor | Single-board, 165 mm x 115 mm |

| Operating Temperature | -40 °C to 70 °C |

| Power Requirements | 9 VDC to 30 VDC (2.5 W typical) |

| Weight | 3.5 oz (100 g) |

| Part Numbers | 784326-01 (Standard), 784326-02 (Extended ruggedness) |

| Software Compatibility | LabVIEW, LabVIEW FPGA, NI-RIO Driver

Product introduction |

NI SBRIO-9607

The NI SBRIO-9607 is a compact, rugged single-board RIO controller that combines a real-time processor, FPGA, and integrated I/O for embedded control and monitoring applications. As part of NI’s Single-Board RIO family, this all-in-one solution eliminates the need for separate components, making it ideal for space-constrained deployments where reliability and performance are critical.

Featuring a dual-core ARM Cortex-A9 processor and Xilinx Zynq-7020 FPGA, the SBRIO-9607 delivers a unique blend of real-time processing and customizable hardware logic. Its integrated I/O—including 8 analog inputs, 2 analog outputs, and 16 digital I/O lines—simplifies system design, while expansion options via the MXM connector allow for scalability. Whether used in industrial machinery control, remote monitoring stations, or embedded test systems, the SBRIO-9607 provides a flexible platform that balances performance, size, and power efficiency.

Core advantages and technical highlights

Integrated Architecture: The NI SBRIO-9607 combines a real-time processor, FPGA, and I/O on a single board, reducing system complexity and improving reliability by minimizing interconnections. This integration eliminates communication delays between components, critical for applications like precision motion control where tight synchronization between processing and I/O is required. The compact form factor (165 mm x 115 mm) makes it suitable for embedded systems with limited space, such as robotic arms or portable test equipment.

Dual-Processor Flexibility: With a dual-core ARM Cortex-A9 processor handling real-time control algorithms and an 85K logic cell FPGA managing high-speed I/O, the SBRIO-9607 enables parallel processing of tasks. Engineers can offload time-critical operations (like encoder feedback processing or pulse-width modulation) to the FPGA, while the real-time processor runs higher-level control logic and communication protocols. This division of labor optimizes performance, ensuring µs-level response times for critical functions.

Rugged Design for Harsh Environments: Engineered to operate in extreme conditions, the SBRIO-9607 supports a wide temperature range (-40 °C to 70 °C) and withstands vibration (10 g rms) and shock (50 g)—qualities essential for industrial, aerospace, and automotive applications. Its wide input voltage range (9 VDC to 30 VDC) simplifies integration into diverse power systems, from battery-powered devices to industrial 24 VDC networks. The solid-state design with no moving parts enhances reliability in mobile or high-vibration environments.

Flexible I/O and Expansion: The SBRIO-9607‘s integrated I/O (8x AI, 2x AO, 16x DIO) covers most basic control and monitoring needs, while the MXM connector supports expansion modules for specialized requirements—such as additional analog channels, high-speed digital I/O, or communication interfaces like Ethernet/IP or Profibus. This modularity allows users to customize the system for specific applications without redesigning the entire board, reducing development time and cost.

Typical application scenarios

In industrial machine control, the NI SBRIO-9607 serves as a compact controller for automated equipment like packaging machines or conveyor systems. It uses its analog inputs to monitor sensor data (temperature, pressure), processes the information in real time, and adjusts actuators via analog outputs or digital I/O—all while communicating with a central SCADA system over Ethernet. The FPGA handles high-speed tasks like encoder counting for motor speed regulation, ensuring precise control even in dynamic operating conditions.

In remote environmental monitoring, the SBRIO-9607 deployed in weather stations or industrial sensor networks collects data from multiple sensors (humidity, air quality, vibration) using its analog inputs. Its low power consumption (2.5 W typical) makes it suitable for battery-powered or solar-equipped installations, while its rugged design ensures reliable operation in outdoor or unconditioned spaces. The controller can log data to its eMMC flash or a microSD card and transmit insights to a cloud platform via Ethernet, enabling remote analysis.

In automotive test systems, the SBRIO-9607 is integrated into on-vehicle data loggers to capture sensor data during road tests. It monitors parameters like engine temperature, braking force, and suspension movement via analog inputs, while the CAN interface connects to the vehicle’s OBD-II system. The FPGA synchronizes data acquisition with vehicle events (e.g., acceleration, braking), ensuring time-stamped data for later analysis. Its compact size and ruggedness allow seamless integration into tight spaces within the vehicle.

NI SBRIO-9607

Related model recommendations

NI SBRIO-9651: A higher-performance single-board RIO with a faster ARM processor (1.3 GHz) and larger FPGA (Zynq-7030, 280K logic cells). It offers more I/O (16 analog inputs, 4 analog outputs) and is ideal for applications requiring greater processing power than the SBRIO-9607.

NI cRIO-9068: A compact RIO controller with a similar Zynq-7020 FPGA but in a modular chassis design. It complements the SBRIO-9607 in systems where I/O needs may grow significantly, as it supports multiple C Series modules.

NI USB-6001: A low-cost USB DAQ device that works with the SBRIO-9607 in hybrid systems. While the SBRIO-9607 handles embedded control, the USB-6001 adds portable data acquisition for benchtop testing or field validation.

NI 9205: A C Series analog input module compatible with the SBRIO-9607 via expansion. It adds 16 additional 16-bit analog inputs, expanding the system’s capability for high-channel-count monitoring applications.

NI SBRIO-9631: A wireless-enabled variant of the SBRIO-9607 with 802.11n Wi-Fi and Bluetooth. It’s ideal for applications where wired Ethernet is impractical, such as mobile robots or remote sensors.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SBRIO-9607, ensure the target environment meets its operating specifications (temperature, voltage, vibration). Mount the board using the provided mounting holes, ensuring proper ventilation to maintain thermal performance. Use anti-static precautions (wrist strap, grounded workspace) when handling the board to prevent damage to the FPGA and other sensitive components. Verify that external power supplies provide 9–30 VDC and are properly fused to protect against overcurrent.

Commissioning: Connect the SBRIO-9607 to a host computer via Ethernet and install NI-RIO drivers and LabVIEW (2018 or later) for configuration. Use NI Measurement & Automation Explorer (MAX) to detect the device and configure network settings. Program the FPGA using LabVIEW FPGA, defining I/O logic for high-speed tasks like timing or signal conditioning. Develop real-time applications on the ARM processor to handle control algorithms and communication, testing with simulated inputs before connecting to actual sensors/actuators. Validate I/O functionality using built-in self-test tools, ensuring analog channels are calibrated to specified accuracy.

Maintenance suggestions: Regularly update the SBRIO-9607‘s firmware and NI Linux Real-Time image via NI Package Manager to access performance improvements and security patches. Monitor flash storage health using diagnostic tools, especially in write-intensive applications, to prevent data loss. Inspect I/O connectors quarterly for corrosion or damage, cleaning with isopropyl alcohol if needed—critical for outdoor or industrial environments. For systems in high-vibration settings, check mounting screws periodically to ensure the board remains securely fastened. Avoid exposing the board to electrostatic discharge during maintenance, and use surge protection on power and communication lines to prevent damage from voltage spikes.

Service and guarantee commitment

NI provides a 3-year warranty for the SBRIO-9607, covering manufacturing defects and ensuring replacement or repair of faulty units at no cost. This warranty reflects NI’s confidence in the board’s rugged design and long-term reliability in embedded applications.

Technical support is available via phone, email, and online forums, with specialists experienced in embedded systems and FPGA programming offering assistance with configuration, programming, and troubleshooting. The NI website provides comprehensive documentation, including user manuals, application notes, and example code for LabVIEW and LabVIEW FPGA.

For customers requiring additional support, NI offers extended service agreements that include priority technical support, on-site assistance, and calibration services traceable to ISO standards. These agreements ensure the SBRIO-9607 continues to perform reliably in critical applications, minimizing downtime and maximizing system availability.