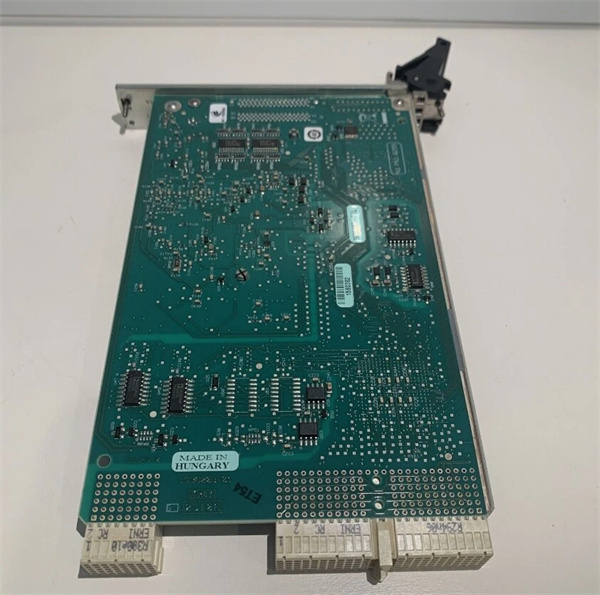

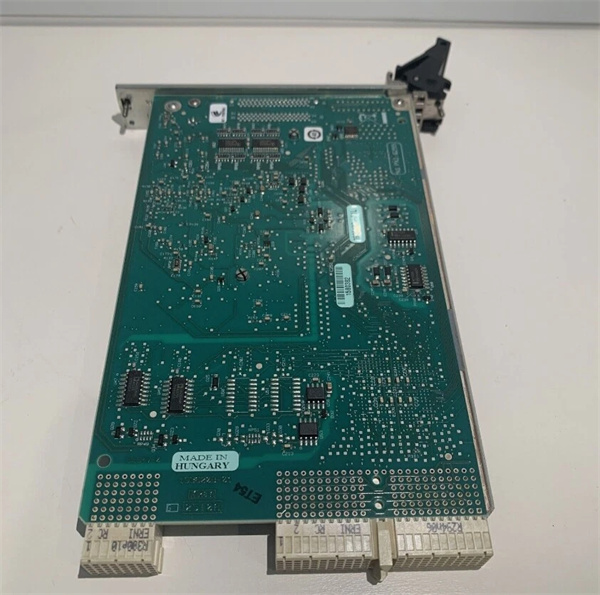

Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI cRIO-9627 783817-01 |

| Manufacturer | National Instruments (NI) |

| Product category | CompactRIO (cRIO) Embedded Controller (Real-Time + FPGA) |

| Processing Core | Real-Time Processor: Dual-core ARM Cortex-A9 (1.33 GHz); FPGA: Xilinx Zynq-7020 (Artix-7 FPGA, 85k logic cells) |

| Memory | 1 GB DDR3 RAM (real-time processor); 256 MB QSPI flash (boot); 8 GB eMMC storage (user data) |

| I/O Expansion | 2 C Series module slots (compatible with NI C Series I/O modules: e.g., NI 9208, NI 9231); Supports hot-swapping of C Series modules |

| Communication Interfaces | 2× Gigabit Ethernet (1× for host communication, 1× for industrial protocols); 1× USB 2.0 (host); 1× RS-232/485 (configurable); 2× 1PPS/IRIG-B (time synchronization) |

| Operating System | NI Linux Real-Time (pre-installed); Supports LabVIEW Real-Time, C/C++, Python programming |

| Physical Dimensions | Compact form factor (146 mm × 102 mm × 54 mm); Weight: ~400 g; Mounting: DIN rail, panel mount, or wall mount (via optional brackets) |

| Environmental Requirements | Operating temperature: -40 °C to 70 °C (extended industrial range); Storage temperature: -40 °C to 85 °C; Relative humidity: 5%–95% (non-condensing, 40 °C); Vibration resistance: 5 g (10 Hz–500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Power Requirements | Input voltage: 9–36 VDC; Typical power consumption: 10 W (no C Series modules); Max power consumption: 25 W (with high-power C Series modules) |

| Safety & Compliance | CE, FCC Class B, UL 61010-1, IEC 61010-1, ATEX Zone 2 (optional); ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge); Isolation: 250 Vrms (C Series module slots to chassis ground) |

| Additional Features | Integrated real-time clock (RTC) with battery backup; Watchdog timer (configurable); Support for industrial protocols: Modbus TCP, Ethernet/IP, PROFINET (via software add-ons) |

| Included Accessories | Power cable (9–36 VDC), DIN rail mounting clip, quick start guide |

NI PXI-6255

Product introduction

The NI cRIO-9627 783817-01 is a compact, rugged CompactRIO embedded controller developed by National Instruments (NI), engineered to deliver real-time control and high-speed data acquisition for edge industrial applications—far beyond the wiring-focused functionality of legacy accessories like the NI SCXI-1325. Unlike SCXI systems that rely on external PCs, the NI cRIO-9627 783817-01 integrates a dual-core ARM real-time processor and Xilinx FPGA in a standalone unit, enabling low-latency (sub-1 ms) control and direct connection to C Series I/O modules (e.g., NI 9208 for analog input, NI 9231 for strain gauges).

As a key model in NI’s modern cRIO lineup, the NI cRIO-9627 783817-01 excels in harsh environments where space and reliability are critical. For example, a renewable energy company uses the NI cRIO-9627 783817-01 to control a solar inverter: its -40 °C to 70 °C operating range withstands desert heat, while the FPGA executes 1 ms control loops to optimize power output. The controller’s two C Series slots support a NI 9208 (voltage monitoring) and NI 9213 (temperature sensing), eliminating the need for separate SCXI chassis like the NI SCXI-1000 and reducing system size by 60%. Whether used in industrial automation, aerospace testing, or smart infrastructure, the NI cRIO-9627 783817-01 provides a scalable, embedded solution for edge computing needs.

Core advantages and technical highlights

Rugged Design for Extreme Industrial Environments: The NI cRIO-9627 783817-01’s -40 °C to 70 °C operating range and 50 g shock resistance far exceed the capabilities of legacy SCXI systems (e.g., NI SCXI-1000’s 0 °C–55 °C range) and make it suitable for harsh edge applications. A mining company, for instance, deploys the NI cRIO-9627 783817-01 to monitor conveyor belt tension: the controller operates in -25 °C winter conditions, while its FPGA processes data from a NI 9231 strain gauge module to detect belt slippage in real time. Without this ruggedness, a PC-based SCXI system would fail due to temperature extremes or vibration, leading to unplanned downtime.

Low-Latency Real-Time + FPGA Processing: The NI cRIO-9627 783817-01 combines a 1.33 GHz dual-core ARM processor (for complex logic) and Xilinx FPGA (for high-speed I/O) to deliver sub-1 ms control latency—critical for time-sensitive applications like motion control or fault detection. An automotive manufacturer uses the controller to test engine fuel injectors: the FPGA generates 10 µs precision trigger signals for a NI 9263 analog output module, while the real-time processor logs injector performance data to local storage. This latency is 10× faster than PC-based SCXI systems (which rely on external DAQ cards like the NI PCI-6024E), ensuring accurate synchronization between control and measurement.

Scalable C Series Integration for Versatile I/O: With two C Series slots, the NI cRIO-9627 783817-01 supports a wide range of I/O types (analog, digital, thermocouple, strain) via NI’s C Series module ecosystem—unlike the NI SCXI-1325, which is limited to analog input wiring. A water treatment plant uses the controller with a NI 9205 (32-channel analog input) and NI 9474 (digital output) module: the NI 9205 monitors pH and chlorine levels, while the NI 9474 controls valves to adjust chemical dosing. The controller’s hot-swapping capability lets technicians replace modules without powering down the system, reducing maintenance downtime by 50% compared to SCXI setups.

Industrial Connectivity & Protocol Support: The NI cRIO-9627 783817-01 includes Gigabit Ethernet, RS-232/485, and support for industrial protocols (Modbus TCP, Ethernet/IP) via software add-ons—enabling seamless integration with factory SCADA systems. A manufacturing plant uses the controller to connect to a Siemens PLC: its Ethernet/IP protocol support allows real-time data exchange (e.g., production counts, machine status) between the NI cRIO-9627 783817-01 (monitoring sensor data) and the PLC (managing production lines). This connectivity eliminates the need for external communication adapters like the NI SCXI-1349, simplifying system architecture and reducing points of failure.

Typical application scenarios

In aerospace ground testing, a defense contractor uses the NI cRIO-9627 783817-01 to validate aircraft landing gear components. The controller’s FPGA processes data from two C Series modules: a NI 9231 (4-channel strain gauge input) to measure gear stress and a NI 9213 (16-channel thermocouple input) to monitor hydraulic fluid temperature. The real-time processor runs a LabVIEW Real-Time application to log data at 1 kHz and trigger an emergency shutdown if stress exceeds safety thresholds. The NI cRIO-9627 783817-01’s -40 °C to 70 °C range withstands the test chamber’s extreme temperature cycles, while its 250 Vrms isolation protects it from voltage transients—ensuring reliable operation for 24/7 testing. This setup replaces a bulky SCXI system (NI SCXI-1000 + NI PCI-6024E), reducing test rig size by 70% and lowering power consumption by 40%.

In smart grid monitoring, a utility company deploys the NI cRIO-9627 783817-01 to monitor a substation’s transformers. The controller connects to a NI 9208 (16-channel analog input) module to measure voltage/current and a NI 9437 (digital input) module to detect circuit breaker status. The FPGA executes a 1 ms control loop to calculate power quality metrics (THD, power factor), while the real-time processor sends data to a cloud dashboard via Gigabit Ethernet. The NI cRIO-9627 783817-01’s DIN rail mounting fits in the substation’s control cabinet, and its ATEX Zone 2 compliance (optional) ensures safety in hazardous environments. This system reduces data latency by 80% compared to a legacy SCXI-based setup, enabling faster detection of power anomalies and reducing downtime for grid maintenance.

NI PXI-6255

Related model recommendations

NI 9208: 16-channel C Series analog input module that pairs with the NI cRIO-9627 783817-01—measures voltage, thermocouples, and RTDs, expanding the controller’s analog measurement capabilities.

NI 9231: 4-channel C Series bridge input module complementary to the NI cRIO-9627 783817-01—adds strain gauge and load cell measurement for structural testing or force monitoring.

NI cRIO-9049: Higher-performance cRIO controller and upgrade of the NI cRIO-9627 783817-01—features a quad-core ARM processor and larger FPGA, ideal for applications requiring more processing power (e.g., multi-axis motion control).

NI 9474: 8-channel C Series digital output module for the NI cRIO-9627 783817-01—controls relays, valves, or LEDs in industrial automation workflows.

NI LabVIEW 2024: Essential software for programming the NI cRIO-9627 783817-01—includes FPGA and Real-Time modules to design control algorithms and data logging applications, reducing development time by 50%.

NI-Industrial Communications for Ethernet/IP: Software add-on for the NI cRIO-9627 783817-01—enables communication with Allen-Bradley PLCs and other Ethernet/IP-compatible devices in factory automation systems.

NI DIN Rail Mounting Kit (781560-01): Optional accessory for the NI cRIO-9627 783817-01—secures the controller to standard DIN rails in industrial control cabinets, simplifying installation.

NI SCXI-1000: Legacy SCXI chassis that the NI cRIO-9627 783817-01 replaces—users migrating from SCXI can use C Series equivalents (e.g., NI 9208 instead of NI SCXI-1100) with the controller for modernization.

NI 9945: Shielded cable for C Series modules (e.g., NI 9208) used with the NI cRIO-9627 783817-01—reduces EMI in industrial environments, preserving signal integrity for low-level measurements.

NI cRIO-9623: Lower-cost cRIO controller and alternative to the NI cRIO-9627 783817-01—features a single-core processor and 1 C Series slot, suitable for basic edge monitoring applications (e.g., environmental sensing).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI cRIO-9627 783817-01, ensure the mounting location (DIN rail, panel) is free from dust, vibration, and extreme temperatures (-40 °C to 70 °C). Use the included DIN rail clip to secure the controller, or use an optional panel-mount bracket for wall installation. Connect a 9–36 VDC power supply to the controller’s power terminal block—ensure correct polarity (positive to +, negative to GND) to avoid damage. Insert C Series modules (e.g., NI 9208) into the two slots: align the module’s guide pins with the controller’s rails, push until it clicks, and secure with the front-panel screw. Connect sensors to the C Series modules using shielded cables (e.g., NI 9945) and power on the controller.

Commissioning and maintenance: Use NI Measurement & Automation Explorer (MAX) to detect the NI cRIO-9627 783817-01 via Gigabit Ethernet—configure network settings (IP address, subnet) for communication with the host PC. Install LabVIEW 2024 with the Real-Time and FPGA modules, then deploy a test application to verify I/O functionality (e.g., read voltage from the NI 9208). Calibrate C Series modules annually using a NIST-traceable reference (e.g., NI 9172) to maintain measurement accuracy. Inspect the controller quarterly: check power connections for tightness, clean the air vents with compressed air to prevent overheating, and verify module connections (reseat modules if communication is lost). Avoid exposing the NI cRIO-9627 783817-01 to humidity above 95% or voltages exceeding 36 VDC—extreme conditions can damage the processor or FPGA. Store spare modules in anti-static bags to prevent ESD damage.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI cRIO-9627 783817-01, covering defects in the real-time processor, FPGA, power supply, and C Series module slots. For extended protection, the NI ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration (traceable to NIST) for integrated components, priority technical support (2-hour response time for aerospace/industrial customers), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team includes cRIO specialists, offering 24/7 support for the NI cRIO-9627 783817-01—assisting with FPGA programming, industrial protocol configuration, and troubleshooting of C Series module integration. Customers gain free access to exclusive resources: application notes on smart grid monitoring with the NI cRIO-9627 783817-01, LabVIEW FPGA example code for real-time control, and a user community for sharing edge computing best practices. For out-of-warranty repairs, NI’s Precision cRIO Restore Service replaces aged components (e.g., processor, memory) and verifies FPGA performance—restoring the NI cRIO-9627 783817-01 to factory specifications. This commitment reflects NI’s confidence in the controller’s durability and dedication to supporting users’ long-term embedded control needs.