Description

Detailed parameter table

| Parameter name | Parameter value |

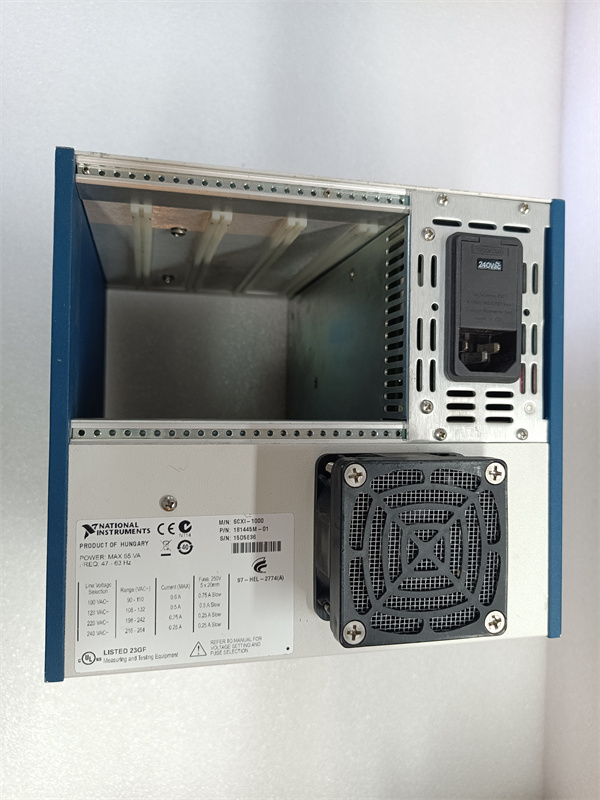

| Product model | NI SCXI-1000 |

| Manufacturer | National Instruments (NI) |

| Product category | Compact SCXI Chassis (Signal Conditioning Chassis) |

| Module Slots | 4 slots (compatible with all NI SCXI signal conditioning modules) |

| Power Supply | 100-240 VAC (50/60 Hz) input; +5 VDC (4 A), ±15 VDC (1 A) output to modules |

| Operating Temperature Range | 0 °C to 55 °C (commercial grade); -20 °C to 60 °C (extended with optional cooling) |

| Storage Temperature Range | -40 °C to 85 °C |

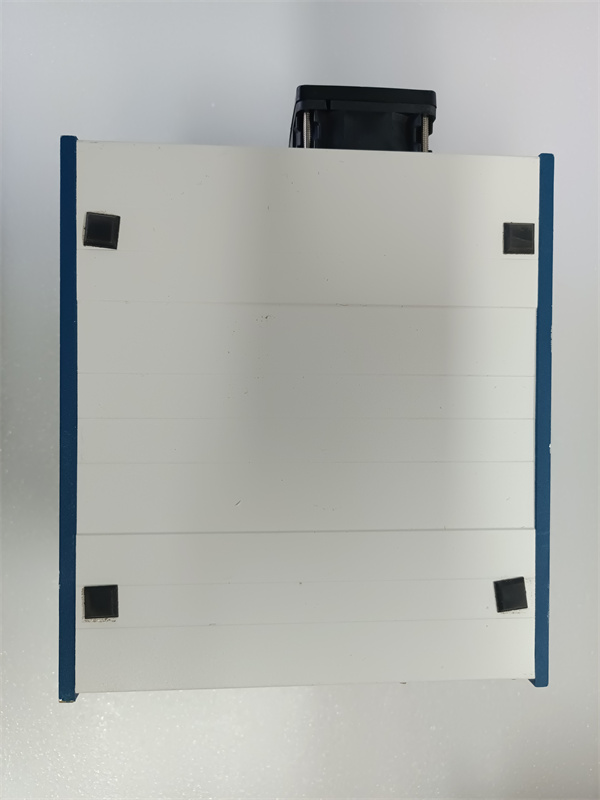

| Dimensions (W×H×D) | 8.5 in × 3.2 in × 10.2 in (216 mm × 81 mm × 259 mm) |

| Weight | 5.5 lb (2.5 kg) |

| Ruggedization Ratings | 10 g peak shock (11 ms), 5-500 Hz vibration (0.5 g rms) |

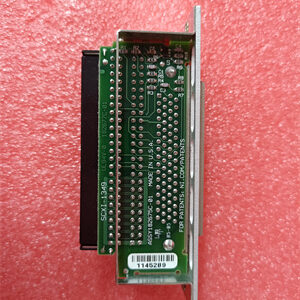

| Communication Interfaces | 1× GPIB (IEEE 488.2), 1× RS-232 (for chassis configuration and control) |

| Cooling System | Forced-air cooling (2 internal fans, temperature-controlled speed) |

| Compatibility | Works with NI DAQ devices (e.g., NI PCI-6221, NI USB-6210) via SCXI-DAQ interface modules |

| Key Functions | Module power distribution, signal routing, chassis management, thermal regulation |

| Safety Certifications | UL 61010-1, CSA C22.2 No. 61010-1, IEC 61010-1 |

NI SCXI-1000

Product introduction

The National Instruments SCXI-1000 is a compact, rugged SCXI chassis, engineered to serve as a centralized platform for housing, powering, and managing NI SCXI signal conditioning modules. As a foundational component of NI’s SCXI ecosystem, it addresses the critical need for reliable signal conditioning in test, measurement, and industrial automation—enabling users to amplify, filter, and isolate low-level signals (e.g., from sensors) before sending them to DAQ devices for measurement.

Designed for flexibility and space efficiency, the NI SCXI-1000 features 4 slots to accommodate SCXI modules (e.g., NI SCXI-1122 analog input modules, NI SCXI-1200 digital I/O modules) while maintaining a small footprint—ideal for benchtop test setups or space-constrained industrial enclosures. When paired with compatible NI DAQ devices (e.g., NI PCI-6221) and SCXI-DAQ interface modules (e.g., NI SCXI-1349), the NI SCXI-1000 creates a seamless signal chain: it distributes power to modules, routes conditioned signals to DAQ devices, and allows remote configuration via GPIB or RS-232. Its temperature-controlled cooling and rugged design also ensure consistent performance in lab and light-industrial environments.

Core advantages and technical highlights

Compact Form Factor for Space-Constrained Setups:

The NI SCXI-1000’s dimensions (8.5 in × 3.2 in × 10.2 in) and 5.5 lb weight make it one of the smallest SCXI chassis in NI’s lineup—perfect for benchtop testing, portable test kits, or industrial enclosures with limited space. Unlike larger 10-slot SCXI chassis (e.g., NI SCXI-1001), it balances slot capacity (4 slots) with portability, enabling users to build focused signal conditioning systems without sacrificing functionality. For example, in a portable sensor testing kit, the NI SCXI-1000 can house a NI SCXI-1122 (4-channel analog input module) and NI SCXI-1200 (digital I/O module) while fitting in a standard equipment case.

Reliable Power Distribution and Thermal Management:

The NI SCXI-1000 delivers stable power (+5 VDC/4 A, ±15 VDC/1 A) to connected SCXI modules, ensuring consistent signal conditioning performance. Its forced-air cooling system—equipped with 2 temperature-controlled fans—adjusts fan speed based on internal chassis temperature, reducing noise during low-load operation and preventing overheating during high-demand tasks (e.g., powering multiple high-current modules). This thermal regulation protects sensitive SCXI components, extending their lifespan and reducing unplanned downtime—critical for long-duration test campaigns.

Flexible Communication and DAQ Integration:

With GPIB and RS-232 interfaces, the NI SCXI-1000 supports easy configuration and control: users can program chassis settings (e.g., fan speed, module addressing) via LabVIEW or NI Measurement & Automation Explorer (MAX) without physical access. It also integrates seamlessly with NI DAQ devices through SCXI-DAQ interface modules: for instance, pairing the NI SCXI-1000 with a NI SCXI-1349 interface module and NI PCI-6221 DAQ card creates a complete system—conditioning 4 channels of low-level sensor signals (via a NI SCXI-1122 module) before digitization. This compatibility eliminates the need for custom wiring or third-party adapters, simplifying system setup.

Rugged Design for Light-Industrial Reliability:

With 10 g shock resistance (11 ms) and 0.5 g rms vibration tolerance (5-500 Hz), the NI SCXI-1000 outperforms generic benchtop chassis in light-industrial environments (e.g., factory test stations, vehicle component labs). Its robust metal enclosure and reinforced connector ports protect internal components from accidental impacts or dust ingress, while safety certifications (UL 61010-1, IEC 61010-1) ensure compliance with global electrical safety standards. For example, in an automotive component test lab, the NI SCXI-1000 can operate reliably near engine test cells, withstanding vibration from nearby machinery.

Typical application scenarios

In academic and research labs, the NI SCXI-1000 is a go-to solution for low-level sensor signal conditioning. For example, in a mechanical engineering lab testing structural vibrations, the NI SCXI-1000 houses a NI SCXI-1122 (4-channel, 16-bit analog input module) to amplify weak signals from accelerometers (typically millivolt-level) before sending them to a NI USB-6210 DAQ device for analysis. The NI SCXI-1000’s compact size fits on lab benches, while its GPIB interface allows students to program data acquisition sequences via LabVIEW—streamlining experiment setup and data collection.

In industrial quality control, the NI SCXI-1000 powers signal conditioning for production line testing. For a electronics manufacturer testing printed circuit boards (PCBs), the NI SCXI-1000 hosts a NI SCXI-1140 (8-channel isolation module) to isolate PCB test signals from electrical noise on the factory floor. It pairs with a NI PCI-6221 DAQ card to measure analog outputs from PCBs, with the NI SCXI-1000’s cooling system ensuring stable performance during 24/7 production runs. Its rugged design also withstands occasional bumps from factory personnel or equipment.

In environmental monitoring, the NI SCXI-1000 enables reliable field-deployed signal conditioning. For a weather research team measuring soil moisture and temperature, the NI SCXI-1000 is paired with a NI SCXI-1102 (8-channel thermocouple module) and NI USB-6210 DAQ device. The NI SCXI-1000’s compact size fits in a portable weather station, while its RS-232 interface allows remote configuration via a laptop. Its extended storage temperature range (-40 °C to 85 °C) also ensures it survives transportation to remote field sites (e.g., deserts, mountain regions).

Related model recommendations

NI SCXI-1001: A 10-slot SCXI chassis and upgraded alternative to the NI SCXI-1000, offering more slots for larger signal conditioning systems (e.g., 8-channel sensor arrays). It shares the same GPIB/RS-232 interfaces and cooling design but supports up to 10 SCXI modules—ideal for scaling beyond the NI SCXI-1000’s 4-slot capacity.

NI SCXI-1122: A 4-channel analog input module designed to work with the NI SCXI-1000. It provides gain (1-1000x) and low-pass filtering for low-level signals (e.g., from strain gages, accelerometers), complementing the NI SCXI-1000’s power and routing capabilities.

NI SCXI-1200: A 32-channel digital I/O module compatible with the NI SCXI-1000. When paired with the chassis, it adds digital control (e.g., relay triggering, sensor power) to signal conditioning systems—useful for mixed-signal test setups.

NI SCXI-1349: A SCXI-DAQ interface module that connects the NI SCXI-1000 to NI DAQ devices (e.g., NI PCI-6221). It routes conditioned signals from the NI SCXI-1000’s modules to the DAQ device, enabling seamless integration between the chassis and measurement hardware.

NI PCI-6221: A multifunction DAQ card that works with the NI SCXI-1000 (via NI SCXI-1349). It digitizes conditioned signals from the chassis, providing 16-bit resolution and 250 kS/s sampling rate—ideal for most lab and light-industrial measurement tasks.

NI USB-6210: A portable USB DAQ device compatible with the NI SCXI-1000. It replaces PCI-based DAQ cards for benchtop or field setups, allowing the NI SCXI-1000 to be used in locations without desktop PCs.

NI SCXI-1140: An 8-channel isolation module for the NI SCXI-1000. It provides 2,500 Vrms channel-to-channel isolation, protecting the NI SCXI-1000 and DAQ devices from high-voltage transients (common in industrial environments).

NI SCXI-1000 Cooling Kit: An optional accessory for the NI SCXI-1000, extending its operating temperature range to -20 °C to 60 °C. It adds a third fan and thermal insulation, making the chassis suitable for colder or hotter environments than its standard 0 °C to 55 °C range.

NI SCXI-1000

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI SCXI-1000, verify that the installation surface (benchtop, rack shelf) can support its 5.5 lb weight and provides at least 2 in of clearance on all sides for airflow. Ensure the environment meets the chassis’ standard operating temperature (0 °C to 55 °C) and avoids direct sunlight, moisture, or excessive dust. Required tools include a Phillips-head screwdriver (for securing modules and chassis feet) and ESD protection gear (wrist strap, mat) to prevent damage to SCXI modules. Before powering on, connect the NI SCXI-1000 to a compatible DAQ device via an SCXI-DAQ interface module (e.g., NI SCXI-1349) and confirm GPIB/RS-232 cables are properly seated. Use only the included 100-240 VAC power cord to avoid electrical hazards.

Maintenance suggestions

For daily maintenance of the NI SCXI-1000, inspect the fan vents weekly for dust buildup—use compressed air (low pressure) to clean vents if needed, as clogged vents can cause overheating. Monitor chassis temperature via LabVIEW or MAX; temperatures exceeding 55 °C indicate a cooling issue (e.g., faulty fan) that requires immediate attention. Every 6 months, check power connections and replace the chassis’ air filters (if using the optional cooling kit) to maintain airflow. When replacing SCXI modules, power off the NI SCXI-1000 first to prevent module or backplane damage. Avoid moving the chassis while powered on, as this can dislodge modules or disrupt signal routing.

Service and guarantee commitment

National Instruments (NI) backs the NI SCXI-1000 with a 2-year standard warranty, covering defects in materials and workmanship under normal use. If the NI SCXI-1000 fails during the warranty period, NI provides free repair or replacement, with expedited service options for critical applications (e.g., production line testing) to minimize downtime. NI’s global technical support team is available 24/7 via email, phone, and online chat, offering assistance with chassis configuration, DAQ integration, and troubleshooting (e.g., fan malfunctions, communication errors). Additionally, NI provides lifetime access to firmware updates, driver downloads, and application notes for the NI SCXI-1000, ensuring compatibility with new SCXI modules and NI software. This commitment reflects NI’s confidence in the NI SCXI-1000’s reliability and helps customers maximize their investment in signal conditioning infrastructure.