Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI SCXI-1000 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy SCXI (Signal Conditioning eXtensions for Instrumentation) Chassis |

| Module Capacity | 8 SCXI module slots (compatible with SCXI analog/digital/counter modules, e.g., NI SCXI-1102, NI SCXI-1327) |

| Signal Conditioning Support | Provides power, signal routing, and conditioning (filtering, amplification, isolation) for SCXI modules; Supports thermocouple cold-junction compensation (CJC) via compatible modules |

| Communication Interface | Parallel interface (for connection to legacy DAQ cards like NI PCI-6024E); Optional GPIB interface (via NI SCXI-1349 adapter); No direct PCIe/PXIe compatibility (legacy parallel bus only) |

| Power Requirements | Input voltage: 100–240 VAC (50/60 Hz); Power consumption: 60 W (max); Built-in power supply for SCXI modules (±5 VDC, ±15 VDC) |

| Physical Dimensions | Desktop/rack-mount form factor (432 mm × 178 mm × 229 mm); Weight: ~5.4 kg; 19-inch rack-mountable (2U height) |

| Environmental Requirements | Operating temperature: 0 °C–55 °C; Storage temperature: -20 °C–70 °C; Relative humidity: 10%–90% (non-condensing); Vibration resistance: 1 g (10 Hz–500 Hz); Shock resistance: 15 g (11 ms half-sine) |

| Compatibility | Works with legacy NI DAQ cards (e.g., NI PCI-6024E, NI AT-MIO-16E-1); Supported OS: Windows XP/Vista/7 (legacy); Compatible software: LabVIEW 8.6–2018, NI-DAQmx 8.6–18.0 |

| Signal Routing | Backplane for analog/digital signal distribution between SCXI modules; Trigger bus (8 lines) for module synchronization; Analog bus for multichannel signal summing/averaging |

| Safety & Compliance | CE, FCC Class A, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge); Isolation: Dependent on installed SCXI modules (e.g., NI SCXI-1125 offers 250 Vrms isolation) |

| Cooling | Built-in fan (2-speed) for thermal management; Temperature-controlled fan speed to reduce noise in lab environments |

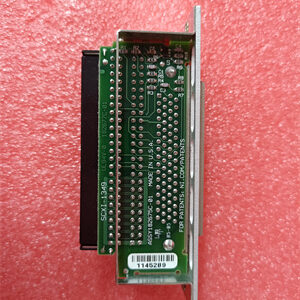

NI SCXI-1000

Product introduction

The NI SCXI-1000 is a legacy SCXI chassis developed by National Instruments (NI), engineered to serve as a centralized hub for signal conditioning and module expansion in legacy data acquisition (DAQ) systems. Unlike modern DAQ platforms like the NI PCIe-6363 (which integrates some conditioning directly), the NI SCXI-1000 is designed to work with legacy DAQ cards (e.g., NI PCI-6024E) to enhance their capabilities—providing noise filtering, amplification, and sensor-specific conditioning for industrial signals (e.g., thermocouples, strain gauges) that require preprocessing before measurement.

As a foundational component of NI’s legacy SCXI ecosystem, the NI SCXI-1000 supports up to 8 SCXI modules, making it ideal for applications where multiple sensor types need centralized conditioning. For example, a manufacturing plant uses the NI SCXI-1000 with a NI PCI-6024E DAQ card to monitor a production line: installed modules include a NI SCXI-1102 (thermocouple input) for temperature, a NI SCXI-1125 (isolated analog input) for voltage, and a NI SCXI-1327 (strain gauge input) for pressure. The NI SCXI-1000 conditions these signals to reduce noise and ensure accuracy, then routes them to the DAQ card for digitization. Unlike the NI PCIe-6363, which requires modern PC hardware, the NI SCXI-1000 extends the life of legacy DAQ systems—critical for industries with long equipment lifecycles (e.g., aerospace, energy).

Core advantages and technical highlights

Centralized Signal Conditioning for Legacy DAQ Systems: The NI SCXI-1000 acts as a “signal preprocessing hub” for legacy DAQ cards that lack built-in conditioning (e.g., NI PCI-6024E). For instance, when measuring thermocouple signals in a noisy factory, the NI SCXI-1000’s compatible NI SCXI-1102 module provides cold-junction compensation (CJC) and 50/60 Hz noise filtering—ensuring temperature accuracy of ±0.5 °C, which the NI PCI-6024E alone cannot achieve. This conditioning is critical for industrial signals, where electrical noise or sensor-specific requirements (e.g., bridge completion for strain gauges) would otherwise invalidate measurements.

8-Slot Scalability for Multi-Sensor Applications: With 8 SCXI module slots, the NI SCXI-1000 enables users to scale their DAQ systems to handle dozens of channels and multiple sensor types—far beyond the channel count of standalone legacy DAQ cards. A power utility, for example, uses the NI SCXI-1000 with 4 NI SCXI-1125 modules (8 channels each) to monitor 32 voltage/current signals in a substation. The chassis’ backplane routes all signals to a single NI PCI-6024E DAQ card, eliminating the need for multiple DAQ cards and simplifying system wiring. This scalability is a key advantage over the NI PCIe-6363, which is limited to its on-board channels and requires modern hardware to expand.

Legacy System Compatibility & Longevity: The NI SCXI-1000 is designed to work with decades-old DAQ cards and operating systems (e.g., Windows XP, LabVIEW 8.6)—making it invaluable for industries that rely on legacy automation systems (e.g., nuclear power, aerospace). A defense contractor, for example, uses the NI SCXI-1000 to maintain a test rig for legacy aircraft components: the chassis connects to a NI AT-MIO-16E-1 DAQ card (1990s-era) and runs on Windows XP, ensuring compatibility with proprietary test software that cannot be updated. Without the NI SCXI-1000, the contractor would face costly system overhauls to replace legacy hardware.

Rugged Design for Industrial Environments: The NI SCXI-1000’s 0 °C–55 °C operating range, 1 g vibration resistance, and built-in fan cooling make it suitable for factory floors and field test sites—conditions where delicate lab equipment would fail. A chemical plant uses the NI SCXI-1000 in a control room to monitor reactor temperatures: its rugged construction withstands dust and temperature fluctuations, while the fan cooling prevents overheating during 24/7 operation. This durability ensures reliable performance in industrial settings, a feature that even modern chassis like the NI cDAQ-9178 (more compact but less rugged) cannot always match for legacy use cases.

Typical application scenarios

In energy sector legacy monitoring, a nuclear power plant uses the NI SCXI-1000 to maintain a safety system for coolant pumps. The chassis is paired with a NI PCI-6024E DAQ card and three SCXI modules: a NI SCXI-1102 (8-channel thermocouple input) to measure pump bearing temperatures, a NI SCXI-1125 (8-channel isolated analog input) to monitor coolant pressure, and a NI SCXI-1327 (4-channel strain gauge input) to detect pump vibration. The NI SCXI-1000 conditions these signals—filtering out electrical noise from the plant’s power grid and amplifying low-level strain signals—before routing them to the DAQ card for digitization. The system runs on Windows XP and LabVIEW 8.6, ensuring compatibility with the plant’s legacy safety software. Without the NI SCXI-1000, the plant would need to replace the entire safety system (costing millions) to use modern DAQ hardware.

In aerospace legacy component testing, a maintenance facility uses the NI SCXI-1000 to test hydraulic valves for older aircraft. The chassis connects to a NI AT-MIO-16E-1 DAQ card and a NI SCXI-1140 (16-channel analog input module) to measure valve pressure and flow rates. The NI SCXI-1000 provides signal amplification (to boost 0–1 V sensor signals to 0–10 V for the DAQ card) and 60 Hz noise filtering (to reduce interference from shop power). The facility’s proprietary test software, written for LabVIEW 2010 and Windows 7, communicates seamlessly with the NI SCXI-1000, enabling automated valve performance tests. This setup extends the life of the facility’s legacy test equipment, avoiding the need to rewrite software or replace hardware.

NI SCXI-1000

Related model recommendations

NI SCXI-1102: 8-channel thermocouple input module for the NI SCXI-1000—provides cold-junction compensation (CJC) and noise filtering for temperature measurements (J/K/T/E/R/S/B/N thermocouples).

NI SCXI-1125: 8-channel isolated analog input module for the NI SCXI-1000—offers 250 Vrms channel-to-channel isolation to protect the DAQ card from voltage transients in industrial environments.

NI PCI-6024E: Legacy PCI DAQ card that pairs with the NI SCXI-1000—digitizes conditioned signals from the chassis (16-bit, 200 kS/s) and connects to Windows XP/Vista systems.

NI SCXI-1349: GPIB adapter for the NI SCXI-1000—adds GPIB communication (replacing the parallel interface) for compatibility with DAQ systems that lack parallel ports.

NI SCXI-1327: 4-channel strain gauge module for the NI SCXI-1000—provides bridge completion (120 Ω/350 Ω) and excitation (2.5 V/5 V) for strain gauge and load cell measurements.

NI LabVIEW 2018: Latest LabVIEW version compatible with the NI SCXI-1000—enables programming of DAQ workflows while maintaining compatibility with legacy VIs.

NI-DAQmx 18.0: Legacy driver for the NI SCXI-1000—supports communication between the chassis, SCXI modules, and legacy DAQ cards (e.g., NI PCI-6024E).

NI cDAQ-9178: Modern CompactDAQ chassis that serves as an upgrade for the NI SCXI-1000—supports C Series modules (e.g., NI 9208) and PCIe/USB communication for users migrating to modern systems.

NI PCIe-6363: Modern PCIe DAQ card that can replace legacy DAQ cards (e.g., NI PCI-6024E) when paired with the NI SCXI-1000 (via adapter)—enabling partial system upgrades while retaining the chassis.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SCXI-1000, ensure the host PC has a compatible legacy DAQ card (e.g., NI PCI-6024E) and parallel port (or GPIB port with NI SCXI-1349). Mount the NI SCXI-1000 in a 19-inch rack (2U height) or place it on a stable desktop—ensure 10 cm clearance around the chassis for airflow. Insert SCXI modules into the 8 slots: align the module’s guide pins with the chassis rails, push until it clicks, then secure with the front-panel screw. Connect the chassis to the DAQ card via the parallel cable (included) or GPIB adapter. Plug the NI SCXI-1000 into a 100–240 VAC outlet, power on the chassis first, then the PC. Install LabVIEW 8.6–2018 and NI-DAQmx 8.6–18.0, then use NI Measurement & Automation Explorer (MAX) to detect the NI SCXI-1000 and verify module communication.

Maintenance suggestions: Inspect the NI SCXI-1000’s fan and air vents monthly—clean dust from vents with compressed air to prevent overheating. Check SCXI module connections quarterly: power off the chassis, remove and reinsert modules to ensure secure seating (loose connections cause signal dropouts). Calibrate SCXI modules (e.g., NI SCXI-1102, NI SCXI-1125) annually using a NIST-traceable reference (e.g., NI 9172) to maintain measurement accuracy. If the NI SCXI-1000 fails to communicate with the DAQ card, check the parallel/GPIB cable (replace if damaged) or update the NI-DAQmx driver (use version 18.0 for legacy compatibility). Avoid exposing the chassis to temperatures above 55 °C or humidity above 90%—extreme conditions can damage the power supply and backplane. Store spare SCXI modules in anti-static bags to prevent ESD damage.

Service and guarantee commitment

National Instruments (NI) provides a 90-day warranty for refurbished NI SCXI-1000 units (new units are no longer manufactured), covering defects in the power supply, backplane, and cooling system. For extended support, the NI Legacy Service Plan offers 1-year coverage, including technical support for module compatibility, troubleshooting of legacy software (e.g., LabVIEW 8.6), and access to archived documentation (user manuals, driver downloads).

NI’s legacy technical team includes SCXI specialists, offering 24/7 support for the NI SCXI-1000—assisting with parallel/GPIB communication issues, module calibration, and compatibility with legacy DAQ cards. Customers gain access to archived resources: application notes on thermocouple testing with the NI SCXI-1000, LabVIEW example code for legacy DAQ workflows, and a community forum for sharing SCXI best practices. For out-of-warranty repairs, NI’s Legacy Chassis Restore Service (parts subject to availability) replaces aged components (e.g., fan, power supply) and verifies backplane signal routing—restoring the NI SCXI-1000 to functional status. This commitment reflects NI’s dedication to supporting users with legacy automation systems that rely on the chassis for critical monitoring and testing.