Description

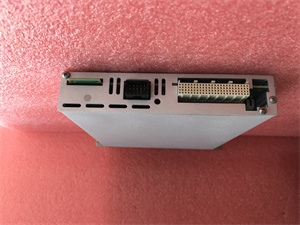

NI SCXI – 1100 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SCXI – 1100 |

| Manufacturer | NI |

| Product Category | Voltage Input Module |

| Number of Channels | 32 differential |

| Input Coupling | DC |

| Maximum Working Voltage | ±10 V |

| Gain Ranges | Multiple, jumper – selectable |

| Filter | Jumper – selectable 4 Hz low – pass filter |

| I/O Connectors | Front: 96 – pin male DIN C connector Rear: 50 – pin male ribbon cable connector |

| Compatibility | SCXI chassis, E series DAQ device |

| Dimensions | 1.2 x 6.8 x 8.0 inches |

| Recommended Operating Temperature Range | 0 °C to 50 °C |

| Obsolete Status | Announced by NI, but still available for purchase and repairs from some sources |

| Part Number | 776572 – 00, 181690 – 01 |

NI SCXI-1100

Product Introduction

The NI SCXI – 1100 is a 32 – differential – channel voltage input module designed for the SCXI system. It serves as a crucial component for affordable signal conditioning of millivolt, volt, and current signals. The module multiplexes all 32 channels, allowing for efficient signal processing. With the option of multiple gain ranges and a jumper – selectable 4 Hz low – pass filter, it can adapt to a wide variety of input signals.

These channels are then multiplexed into a single channel of a controlling data acquisition (DAQ) device, effectively increasing the channel count of the DAQ system. The SCXI – 1100 comes equipped with a 96 – pin male DIN C front connector and a 50 – pin male ribbon cable rear connector for seamless connection with other components in the SCXI setup.

Core Advantages and Technical Highlights

High – Channel – Count Multiplexing: The 32 – differential – channel configuration of the SCXI – 1100 enables it to handle a large number of input signals simultaneously. This is highly beneficial in applications where multiple sensors or signal sources need to be monitored. By multiplexing these channels into a single output for the DAQ device, it optimizes the use of the DAQ system’s resources, allowing for more channels to be added to the overall setup without overloading the DAQ device.

Flexible Signal Conditioning: The availability of multiple jumper – selectable gain ranges makes the SCXI – 1100 adaptable to different signal levels. Whether dealing with small millivolt signals from sensitive sensors or larger volt – level signals, the appropriate gain can be easily set. The 4 Hz low – pass filter, also jumper – selectable, helps in reducing high – frequency noise, ensuring clean and accurate signal conditioning. This flexibility in signal conditioning is crucial for obtaining reliable data in various industrial and laboratory applications.

Cold – Junction Compensation for Thermocouples: The terminal block associated with the SCXI – 1100 includes a temperature sensor for cold – junction compensation of thermocouples. This feature is essential when using thermocouples for temperature measurement. The cold – junction reference can be multiplexed with the 32 channels on the module or jumper – connected to a different channel of the data acquisition board, providing options for different measurement setups. This accurate cold – junction compensation ensures precise temperature readings from thermocouple sensors.

Compatibility with Multiple Terminal Blocks: The SCXI – 1100 is compatible with a wide range of terminal blocks, such as the SCXI – 1300, SCXI – 1303, SCXI – 1308, BNC – 2095, TC – 2095, TBX – 1303, TBX – 96, and SCXI – 1310. Each of these terminal blocks may have unique features, like the SCXI – 1310 with its affordable connector and shell assembly, or the BNC – 2095 with prewired ground referencing. This compatibility allows users to choose the most suitable terminal block based on their specific application requirements, further enhancing the versatility of the SCXI – 1100.

Typical Application Scenarios

Industrial Process Monitoring: In industrial settings, the SCXI – 1100 can be used to monitor various parameters in manufacturing processes. For example, it can be connected to temperature sensors, pressure transducers, and strain gauges distributed throughout a production line. The 32 differential channels can simultaneously acquire signals from these sensors, and the signal conditioning capabilities ensure accurate data acquisition. The multiplexing feature allows for efficient use of the DAQ system, enabling real – time monitoring of multiple process variables to maintain quality control and optimize production efficiency.

Laboratory Research in Physics and Engineering: In research laboratories, the SCXI – 1100 is useful for experiments that require the measurement of multiple analog signals. In a physics experiment studying the behavior of materials under different conditions, it can be connected to sensors measuring electrical signals, magnetic fields, and temperature. The flexible signal conditioning and high – channel – count multiplexing enable researchers to collect comprehensive data from multiple sensors simultaneously. The cold – junction compensation for thermocouples is particularly useful in temperature – related experiments, ensuring accurate temperature measurements.

Power Generation and Distribution Monitoring: In power plants or electrical distribution systems, the SCXI – 1100 can be employed to monitor voltage, current, and temperature in transformers, generators, and power lines. The ability to handle multiple differential channels allows for the simultaneous monitoring of different phases and components. The signal conditioning features help in filtering out electrical noise and accurately measuring the signals, which is crucial for ensuring the reliable operation of the power system and for early detection of any potential faults.

NI SCXI-1100

Related Model Recommendations

NI SCXI – 1125: This is an 8 – channel isolated analog input module. It offers isolation capabilities, which can be beneficial in applications where electrical isolation between the sensors and the DAQ system is required, such as in high – voltage or noisy environments. If the application has a lower channel – count requirement but needs isolation, the SCXI – 1125 could be a suitable alternative to the SCXI – 1100.

NI SCXI – 1140: A digital I/O module, the SCXI – 1140 is designed for applications that deal with digital signals rather than analog voltage signals like the SCXI – 1100. It can be used to interface with digital sensors, actuators, and other digital – based control systems. If the application’s focus is on digital signal processing and control, the SCXI – 1140 would be a more appropriate choice.

NI SCXI – 1000 Chassis: As mentioned earlier, the SCXI – 1000 is a four – slot chassis that houses SCXI modules, including the SCXI – 1100. It provides power and a communication backplane for the modules. When using the SCXI – 1100, the SCXI – 1000 chassis forms the core of the SCXI system, allowing for easy integration and control of multiple modules. If you are building an SCXI – based data acquisition or control system, the SCXI – 1000 chassis is an essential component to consider.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the SCXI – 1100, ensure that the SCXI chassis is properly set up and powered off to avoid electrical hazards. Gather the necessary tools, such as a screwdriver for any mechanical adjustments. Also, make sure you have the appropriate cable adapters, like the SCXI – 1349 cable adapter if connecting to an E series DAQ device. Identify the slot in the SCXI chassis where the module will be installed.

Commissioning: Install the SCXI – 1100 in the designated slot of the SCXI chassis. Connect the 68 – to – 68 – pin cable between the SCXI – 1100 module and the E series DAQ device using the SCXI – 1349 cable adapter. Configure the hardware using NI Measurement & Automation Explorer (MAX). Set all jumpers on the SCXI – 1100 to their factory – default settings as per the module’s manual. Power on the SCXI chassis and verify that the module is recognized by the system. Test the basic functionality by connecting some known input signals and checking if the signals are being correctly acquired and conditioned using appropriate software, such as NI – DAQ.

Maintenance Suggestions: Regularly inspect the SCXI – 1100 for any signs of physical damage, such as cracks on the housing or loose connectors. Check the jumper settings to ensure they have not been accidentally changed. Since the module does not store user – adjustable calibration constants, periodically verify its performance using a high – precision voltage source with at least 50 ppm accuracy and an E series DAQ device. Use shielded copper wire for all cable connections to the module and twisted – pair wire to minimize noise and thermal offsets. Allow sufficient warm – up time (at least 15 minutes for the SCXI module and 30 minutes for the E series DAQ device) before taking measurements to ensure stable operating conditions.

Service and Guarantee Commitment

Although NI has announced the obsolete status of the SCXI – 1100, some sources still offer it for purchase and repairs. While NI’s standard warranty coverage may be limited due to the obsolete status, some third – party suppliers may provide their own warranties. Technical support may also be available through NI’s official channels, including online resources and user forums. However, for in – depth support, users may need to rely on third – party service providers. In case of any issues, users can refer to the NI documentation available at ni.com/manuals, which includes the SCXI – 1100 user manual and calibration documents. If the module is found to be defective within the warranty period (if applicable), the supplier should be contacted for repair or replacement options.