Description

NI SCXI-1104C Product Description

**

Detailed parameter table

| Parameter name | Parameter value |

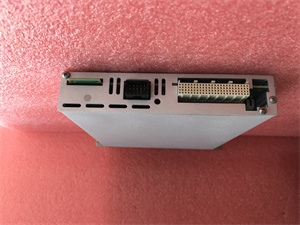

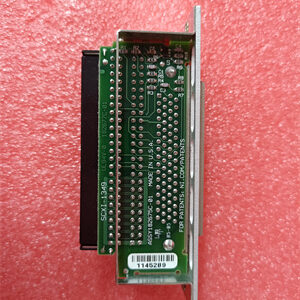

| Product model | SCXI-1104C |

| Manufacturer | NI |

| Product category | Signal Conditioning Module |

| Channel Configuration | 32 differential channels |

| Voltage Range | ±42 VAC / ±60 VDC |

| Filter Type | 3-pole low pass filter on each channel |

| Bandwidth | 10 kHz (SCXI-1104C) |

| Attenuator Stage | Divide-by-10 before amplifier on each channel |

| Multiplexing | Multiplexes inputs to a single module output for DAQ device |

| Scxi Bus Interface | Connects back signal connector to SCXI bus for DAQ control |

| Front Connector | 96-pin male DINC |

| Rear Connector | 50-pin male ribbon cable |

| Dimensions | 4.54 x 10.75 in. |

| Operating Temperature | 0 to 50 °C |

| Storage Temperature | –55 to 150 °C |

| Relative Humidity | 5% to 90%, non-condensing |

| Part Number | 776572 – 04C |

| Compatibility | Designed for use with NI data acquisition (DAQ) devices |

| Calibration | Factory calibrated, periodic calibration recommended |

NI SCXI-1104C

Product introduction

The NI SCXI-1104C is a high-performance 32-channel medium-voltage input signal conditioning module, part of NI’s Signal Conditioning Extensions for Instrumentation (SCXI) series. Engineered to interface with NI data acquisition (DAQ) devices, it plays a crucial role in ensuring accurate and reliable signal conditioning for a wide range of applications.

With its 32 differential analog input channels, the SCXI-1104C can handle medium-voltage signals, including 30 VAC rms, ±42 VAC peak, and ±60 VDC. Each channel features a divide-by-10 attenuator stage before the amplifier, enhancing its versatility in dealing with different signal levels. The module’s 3-pole low pass filter, with a 10 kHz cut-off frequency (specific to the -C variant), effectively removes high-frequency noise, ensuring clean and stable signals for subsequent processing. Whether deployed in industrial monitoring, test and measurement setups, or research laboratories, the SCXI-1104C provides a robust solution for conditioning medium-voltage analog signals.

Core advantages and technical highlights

High Channel Count and Differential Inputs: The NI SCXI-1104C‘s 32 differential channels allow for simultaneous monitoring of multiple signals, reducing the need for multiple modules in high-channel-count applications. Differential inputs are highly resistant to common-mode noise, which is prevalent in industrial environments. This makes the module ideal for applications where accurate measurement of small voltage differences is crucial, such as in sensor arrays or multi-channel data logging systems. The differential configuration also improves the signal-to-noise ratio, resulting in more accurate and reliable data acquisition.

Versatile Voltage Handling: With a wide voltage range of ±42 VAC / ±60 VDC, the SCXI-1104C can accommodate a variety of medium-voltage signals. This flexibility makes it suitable for applications involving different types of sensors, actuators, or electrical systems. The divide-by-10 attenuator stage on each channel further extends its voltage handling capabilities, allowing it to interface with both high and low voltage sources. Whether measuring signals from industrial sensors operating at high voltages or delicate transducers with low-level outputs, the SCXI-1104C can adapt to the requirements.

Effective Noise Filtration: The 3-pole low pass filter on each channel, with a 10 kHz cut-off frequency for the SCXI-1104C, is designed to eliminate high-frequency noise that could otherwise corrupt the acquired signals. In industrial settings, where electrical interference is common, this filtering feature is essential for ensuring the integrity of the data. By removing unwanted noise, the module improves the accuracy of measurements, enabling more precise analysis and control. The filter’s design strikes a balance between signal fidelity and noise reduction, making it suitable for a wide range of applications, from slow-varying sensor signals to moderately fast analog waveforms.

Seamless Integration with NI DAQ Ecosystem: As part of the SCXI series, the SCXI-1104C is optimized for use with NI DAQ devices. This integration simplifies system setup and configuration, as the module is recognized and managed by NI’s software tools, such as NI-DAQmx. The SCXI bus interface allows for efficient communication between the module and other components in the SCXI chassis, enabling seamless data transfer and control. This compatibility extends to NI’s programming environments, including LabVIEW and LabWindows/CVI, making it easy for engineers to develop custom applications that leverage the module’s capabilities. Whether building a simple data acquisition system or a complex automated test setup, the SCXI-1104C’s integration with the NI ecosystem streamlines the development process.

Typical application scenarios

In industrial process monitoring, the NI SCXI-1104C is used to condition signals from a variety of sensors distributed throughout a manufacturing plant. It can monitor temperature, pressure, and voltage sensors, providing accurate and noise-free data to a central control system. For example, in a chemical processing plant, the module can handle the medium-voltage signals from pressure transducers, ensuring that the pressure levels in reactors and pipelines are continuously monitored. The high channel count allows for simultaneous monitoring of multiple critical points in the process, enabling operators to detect and respond to any anomalies promptly. The filtered and conditioned signals are then sent to a DAQ device for further analysis and control.

In power quality monitoring applications, the SCXI-1104C plays a vital role in measuring and analyzing electrical parameters. It can capture voltage and current signals from power distribution systems, filtering out any noise or harmonics. By accurately measuring parameters such as voltage fluctuations, harmonics, and power factor, the module helps in assessing the quality of power supplied to industrial equipment. This data is crucial for preventing equipment damage, optimizing energy consumption, and ensuring compliance with power quality standards. The module’s ability to handle medium-voltage signals directly from the power lines simplifies the monitoring setup, eliminating the need for additional voltage transformation in many cases.

In research and development laboratories, the SCXI-1104C is used for a wide range of experiments that require precise signal conditioning. It can interface with various sensors and transducers used in scientific research, such as those measuring strain, vibration, or electrical properties of materials. For instance, in a materials testing laboratory, the module can condition signals from strain gauges attached to test specimens. The differential inputs and noise filtering capabilities ensure accurate measurement of minute changes in strain, even in the presence of environmental noise. The high channel count also allows researchers to conduct multi-parameter experiments simultaneously, accelerating the research process and providing more comprehensive data for analysis.

NI SCXI-1104C

Related model recommendations

NI SCXI-1104: A predecessor to the SCXI-1104C with a 2 Hz cut-off frequency on its low pass filter, making it suitable for applications where very low-frequency signals need to be captured with minimal high-frequency interference. It has the same 32 differential channels and voltage handling capabilities but may be more appropriate for applications where slower signal variations are of interest, such as long-term environmental monitoring or certain types of biological signal measurements.

NI SCXI-1102C: This module offers high-accuracy analog input conditioning with programmable gain and filtering. While it has fewer channels compared to the SCXI-1104C, it is ideal for applications where a smaller number of channels are required, but precise control over gain and filtering is crucial. It can be used in applications such as single-sensor or small-sensor-array setups where custom signal conditioning parameters are needed.

NI SCXI-1112: Designed specifically for thermocouple inputs, the SCXI-1112 is complementary to the SCXI-1104C in applications where temperature measurement is a key requirement. In systems where both medium-voltage signals and thermocouple-based temperature readings are needed, these two modules can be used together within the same SCXI chassis. The SCXI-1112 provides accurate temperature monitoring, while the SCXI-1104C handles other analog signals.

NI SCXI-1124: For applications that require analog output capabilities, the SCXI-1124 can be paired with the SCXI-1104C. The SCXI-1124 generates voltage and current signals for control applications, such as driving actuators or providing excitation signals. In a closed-loop control system, the SCXI-1104C can acquire sensor data, while the SCXI-1124 can be used to output control signals based on the processed data, creating a complete control and monitoring solution.

NI SCXI-1000 Chassis: This rugged chassis is designed to house SCXI modules, including the SCXI-1104C. It provides the physical enclosure and power distribution for the modules, ensuring reliable operation in various environments. The SCXI-1000 chassis also facilitates the interconnection of multiple modules through the SCXI bus, enabling the creation of complex multi-module systems for more comprehensive data acquisition and control applications.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SCXI-1104C, ensure that the SCXI chassis (such as the SCXI-1000) is properly grounded and powered off. Verify that the chassis has an available slot compatible with the SCXI-1104C module. Use anti-static precautions, such as wearing an anti-static wrist strap and working on a grounded surface, to prevent electrostatic discharge from damaging the module. Check the specifications of the external signals that will be connected to the module to ensure they are within the ±42 VAC / ±60 VDC voltage range. Gather the necessary cables, such as the 50-pin ribbon cable for the rear connector and any appropriate front panel connection cables, depending on the application requirements.

Commissioning: Insert the SCXI-1104C module into the available slot in the SCXI chassis, ensuring that it is properly seated and locked in place. Power on the chassis and connect the SCXI system to a host computer with the appropriate NI-DAQ drivers installed. Use NI Measurement & Automation Explorer (MAX) to detect the module and configure its settings, such as channel mapping and filter parameters. Calibrate the module using a high-precision voltage source and a digital multimeter, following the calibration procedure outlined in the NI documentation. This step is crucial for ensuring accurate signal measurement. Test the module by applying known input signals within the specified voltage range and verifying that the output signals, as measured by the connected DAQ device, are as expected. Use NI software tools, such as LabVIEW, to develop and test applications that interface with the SCXI-1104C.

Maintenance suggestions: Regularly check the module for any signs of physical damage, such as bent pins on the connectors or visible signs of overheating. Inspect the cables connected to the module for any signs of wear or corrosion, especially in harsh environments. Periodically calibrate the module, as recommended by NI (usually at least once a year, but more frequently depending on the application’s accuracy requirements). Use NI’s software tools to monitor the performance of the module, such as checking for any abnormal noise levels in the acquired signals. If the module is used in an environment with high electromagnetic interference, consider using additional shielding or filtering measures to protect the module and ensure reliable operation. Keep the module’s firmware up to date by installing any available updates from NI, as these may include performance improvements and bug fixes.

Service and guarantee commitment

NI offers a standard 1-year warranty for the SCXI-1104C module, covering any manufacturing defects that may occur during normal use. This warranty ensures that in the event of a malfunction, NI will repair or replace the module at no cost to the customer. The warranty reflects NI’s confidence in the quality and reliability of the product.

Technical support is available through NI’s dedicated support channels, including phone, email, and online resources. NI’s technical experts are well-versed in SCXI products and can provide assistance with installation, configuration, calibration, and troubleshooting. The NI website offers a wealth of documentation, including user manuals, application notes, and software drivers, to help users make the most of the SCXI-1104C. For customers with more complex requirements or who need additional support, NI also provides extended service agreements. These agreements can include priority technical support, on-site maintenance, and access to NI’s advanced engineering resources, ensuring that the SCXI-1104C continues to operate at peak performance in critical applications.