Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI SCXI-1102B |

| Manufacturer | National Instruments (NI) |

| Product category | 8-Channel Thermocouple Input Signal Conditioning Module |

| Input Channels | 8 differential channels (dedicated to thermocouple measurements) |

| Supported Thermocouple Types | J, K, T, E, R, S, B, N (software-selectable per channel) |

| Temperature Measurement Range | -270 °C to 1820 °C (depends on thermocouple type: e.g., K-type: -270 °C to 1372 °C; B-type: 0 °C to 1820 °C) |

| Measurement Accuracy | ±0.1 °C (typical at 25 °C for K-type; ±0.3 °C maximum over operating range) |

| Resolution | 16-bit ADC (integrated with SCXI chassis DAQ interface) |

| Cold-Junction Compensation (CJC) | Built-in precision CJC sensor (±0.5 °C accuracy), auto-calibrated |

| Input Impedance | >10 GΩ (differential, ensures minimal loading on thermocouple signals) |

| Filtering | 50/60 Hz notch filter (switchable) + low-pass filter (1 Hz, 10 Hz, 100 Hz software-selectable) |

| Operating Temperature Range | 0 °C to 55 °C (compatible with NI SCXI-1000’s standard range) |

| Storage Temperature Range | -40 °C to 85 °C |

| Chassis Compatibility | All NI SCXI chassis (e.g., NI SCXI-1000, NI SCXI-1001) |

| Power Requirements | +5 VDC (120 mA), ±15 VDC (30 mA) from SCXI chassis backplane |

| Weight | 3.5 oz (100 g) |

| Key Functions | Thermocouple signal amplification, cold-junction compensation, noise filtering, channel multiplexing |

| Safety Certifications | UL 61010-1, CSA C22.2 No. 61010-1, IEC 61010-1 |

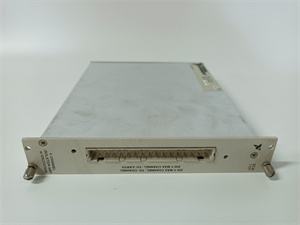

NI SCXI-1121

Product introduction

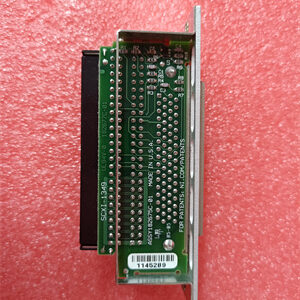

The National Instruments SCXI-1102B is a specialized 8-channel thermocouple input module, engineered to deliver high-accuracy temperature measurements by conditioning weak thermocouple signals—critical for test, measurement, and industrial automation applications where precise thermal monitoring is essential. As a key member of NI’s SCXI signal conditioning lineup, it is designed to work seamlessly with SCXI chassis like the NI SCXI-1000, addressing the unique challenges of thermocouple measurements (e.g., low signal voltage, cold-junction error) to ensure reliable data.

Optimized for thermocouple-based temperature sensing, the NI SCXI-1102B supports 8 differential channels and all common thermocouple types (J, K, T, E, R, S, B, N), with software-selectable configurations per channel. When paired with the NI SCXI-1000 chassis and a compatible NI DAQ device (e.g., NI PCI-6221 via NI SCXI-1349 interface), the NI SCXI-1102B forms a complete thermal measurement system: it amplifies millivolt-level thermocouple signals, compensates for cold-junction temperature drift via a built-in sensor, filters out electrical noise, and routes conditioned signals to the DAQ device for digitization. Its compact design and low power consumption make it ideal for integrating into space-constrained setups, from lab benches to industrial enclosures.

Core advantages and technical highlights

High-Accuracy Measurements with Built-In CJC:

The NI SCXI-1102B eliminates cold-junction error—one of the biggest sources of inaccuracy in thermocouple measurements—via a built-in precision cold-junction compensation (CJC) sensor. With ±0.5 °C CJC accuracy, it automatically adjusts for temperature changes at the module’s terminals (where thermocouples connect), ensuring measurements remain reliable even as ambient temperatures fluctuate (0 °C to 55 °C). Combined with ±0.1 °C typical measurement accuracy for K-type thermocouples, the NI SCXI-1102B outperforms generic thermocouple modules, making it suitable for applications like semiconductor wafer processing or pharmaceutical manufacturing, where temperature deviations of 0.5 °C can compromise product quality.

Multi-Type Thermocouple Support and Channel Flexibility:

Unlike single-type thermocouple modules, the NI SCXI-1102B supports 8 common thermocouple types (J, K, T, E, R, S, B, N), with software-selectable configurations per channel. This flexibility allows users to monitor multiple temperature ranges in a single system: for example, in an automotive engine test, the NI SCXI-1102B can use K-type thermocouples (for -270 °C to 1372 °C) to measure exhaust temperatures and T-type (for -270 °C to 400 °C) to monitor cabin heating—all via the same module in a NI SCXI-1000 chassis. This eliminates the need for multiple modules, reducing system cost and complexity.

Robust Noise Filtering for Industrial Environments:

Thermocouple signals are inherently weak (millivolt-level), making them susceptible to electrical noise (e.g., 50/60 Hz power line interference). The NI SCXI-1102B addresses this with switchable 50/60 Hz notch filters and software-selectable low-pass filters (1 Hz, 10 Hz, 100 Hz). The notch filter eliminates power-line noise, while the low-pass filter smooths out high-frequency fluctuations (e.g., from nearby motors). When used in a NI SCXI-1000 chassis—with its rugged metal enclosure and isolated power—the NI SCXI-1102B maintains signal integrity even in noisy industrial settings, such as factory floors or power generation facilities.

Seamless Integration with SCXI Ecosystem:

The NI SCXI-1102B is designed to plug directly into SCXI chassis like the NI SCXI-1000, leveraging the chassis’ power distribution, signal routing, and DAQ integration capabilities. It draws power (+5 VDC, ±15 VDC) from the NI SCXI-1000’s backplane, eliminating the need for external power supplies, and uses the chassis’ SCXI-DAQ interface (e.g., NI SCXI-1349) to connect to DAQ devices. This integration simplifies system setup: users can configure the NI SCXI-1102B (e.g., select thermocouple types, set filters) via LabVIEW or NI MAX, and the module automatically synchronizes with the NI SCXI-1000’s timing to ensure consistent data acquisition across all channels.

Typical application scenarios

In pharmaceutical manufacturing, the NI SCXI-1102B is critical for monitoring temperature in sterile processing (e.g., autoclave sterilization). Paired with a NI SCXI-1000 chassis and NI USB-6210 DAQ device, it uses T-type thermocouples (for -270 °C to 400 °C) to measure temperature at 8 points inside an autoclave. The NI SCXI-1102B’s built-in CJC ensures accuracy even as the autoclave’s ambient temperature changes, while its 50 Hz notch filter eliminates noise from facility power systems. LabVIEW software logs data in real time, ensuring compliance with FDA regulations for process traceability—any temperature deviation beyond ±0.5 °C triggers an alert, preventing batch contamination.

In aerospace component testing, the NI SCXI-1102B monitors thermal stress on engine parts (e.g., turbine blades). Installed in a NI SCXI-1000 chassis mounted near a test cell, it uses R-type thermocouples (for 0 °C to 1768 °C) to measure temperatures at 8 blade locations. The NI SCXI-1102B’s high-temperature measurement range (up to 1820 °C) and ±0.3 °C maximum accuracy capture subtle thermal gradients, while its low-pass filter (10 Hz) smooths out vibrations from the test engine. The NI SCXI-1000’s rugged design (10 g shock resistance) protects the module from test cell vibrations, ensuring continuous operation during 24-hour test cycles.

In food processing, the NI SCXI-1102B ensures consistent cooking temperatures in industrial ovens. Connected to a NI SCXI-1000 chassis and NI PCI-6221 DAQ card, it uses K-type thermocouples to monitor 8 zones in a conveyor oven. The NI SCXI-1102B’s software-selectable channels allow operators to adjust thermocouple types if switching between baking (low temperature, T-type) and roasting (high temperature, K-type). Its CJC compensates for temperature changes at the oven’s control panel, while the NI SCXI-1000’s compact size fits in the oven’s control cabinet. Real-time data from the NI SCXI-1102B is used to adjust oven heating elements, reducing product waste from undercooked or overcooked items.

NI SCXI-1121

Related model recommendations

NI SCXI-1102: The predecessor to the NI SCXI-1102B, with identical channel count (8) and thermocouple support but slightly lower accuracy (±0.2 °C typical vs. ±0.1 °C for the NI SCXI-1102B). It’s a cost-effective replacement option for legacy systems where ultra-high accuracy isn’t required.

NI SCXI-1104: A 16-channel thermocouple module that upgrades the NI SCXI-1102B’s 8-channel capacity. Designed for larger thermal monitoring systems (e.g., 16-zone industrial ovens), it shares the NI SCXI-1102B’s CJC, filtering, and SCXI chassis compatibility—ideal for scaling beyond the NI SCXI-1102B’s 8 channels.

NI SCXI-1000: The compact 4-slot SCXI chassis that hosts the NI SCXI-1102B. It provides power, cooling, and DAQ integration, making it the primary chassis for small to medium thermocouple measurement setups using the NI SCXI-1102B.

NI SCXI-1349: A SCXI-DAQ interface module that connects the NI SCXI-1102B (installed in NI SCXI-1000) to DAQ devices like the NI PCI-6221. It routes conditioned thermocouple signals from the NI SCXI-1102B to the DAQ device for digitization.

NI PCI-6221: A multifunction DAQ card compatible with the NI SCXI-1102B (via NI SCXI-1349). It digitizes the NI SCXI-1102B’s conditioned signals with 16-bit resolution and 250 kS/s sampling rate, suitable for most thermal measurement tasks.

NI USB-6210: A portable USB DAQ device that pairs with the NI SCXI-1102B and NI SCXI-1000 for field-deployed thermal monitoring (e.g., environmental research). It replaces PCI-based DAQ cards, enabling the NI SCXI-1102B to be used in remote locations.

NI SCXI-1140: An 8-channel isolation module that works with the NI SCXI-1102B in high-noise environments. It provides 2,500 Vrms isolation between the NI SCXI-1102B and DAQ devices, protecting the module from voltage transients (e.g., in power plants).

NI TC-2003: A thermocouple extension cable set designed for the NI SCXI-1102B. It includes 8 shielded cables (2 m length) with color-coded connectors for easy thermocouple-to-module wiring, ensuring signal integrity over long distances.

NI SCXI-1121

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI SCXI-1102B into a NI SCXI-1000 chassis, power off the chassis and wear ESD protection gear (wrist strap, mat) to prevent electrostatic damage. Verify that the NI SCXI-1000 has an available slot and that its firmware is up-to-date (via NI MAX) for compatibility. Gather required tools: a Phillips-head screwdriver (to secure the module to the chassis) and thermocouple wires (compatible with the types you’ll use, e.g., K-type). When wiring thermocouples to the NI SCXI-1102B, ensure correct polarity (positive/negative leads match module terminals) and use shielded wires to minimize noise. Connect the NI SCXI-1000 to a DAQ device via an NI SCXI-1349 interface module before powering on—this ensures the NI SCXI-1102B can communicate with the DAQ device for configuration.

Maintenance suggestions

For daily maintenance of the NI SCXI-1102B, inspect thermocouple connections weekly for corrosion or loose terminals—clean terminals with a dry, lint-free cloth and re-tighten if needed, as poor connections cause measurement errors. Calibrate the module’s CJC sensor annually using a precision temperature reference (e.g., NI TC Calibrator) to maintain ±0.5 °C CJC accuracy. Monitor the NI SCXI-1102B’s filter status via NI MAX; if noise appears in measurements, verify the 50/60 Hz notch filter is enabled (matching your facility’s power frequency). When replacing the NI SCXI-1102B in the NI SCXI-1000 chassis, power off the chassis first and save module configurations (thermocouple types, filters) in NI MAX to simplify reconfiguration of the new module. Avoid exposing the NI SCXI-1102B to extreme temperatures (>55 °C) or moisture, as this degrades the CJC sensor and ADC performance.

Service and guarantee commitment

National Instruments (NI) backs the NI SCXI-1102B with a 2-year standard warranty, covering defects in materials and workmanship under normal use. If the NI SCXI-1102B fails during the warranty period—e.g., due to a faulty CJC sensor or ADC—NI provides free repair or replacement, with expedited service options for critical applications (e.g., pharmaceutical manufacturing) to minimize downtime. NI’s global technical support team is available 24/7 via email, phone, and online chat, offering assistance with module configuration (e.g., thermocouple type selection, filter setup), troubleshooting (e.g., noise issues, CJC errors), and integration with NI SCXI-1000 chassis or DAQ devices. Additionally, NI provides lifetime access to firmware updates, driver downloads, and application notes for the NI SCXI-1102B, ensuring compatibility with new SCXI hardware and NI software (e.g., LabVIEW 2025+). This commitment reflects NI’s confidence in the NI SCXI-1102B’s reliability and helps customers maximize their investment in precision thermal measurement systems.