Description

1. Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product Model | SCXI – 1124 |

| Manufacturer | National Instruments (NI) |

| Product Category | Isolated Analog Output Module for SCXI Systems |

| Output Channels | 6 independent, isolated channels |

| Resolution | 12 – bit Digital – to – Analog Converter (DAC) |

| Voltage Output Ranges | Three unipolar: [0, specified max voltage], [0, specified mid voltage], [0, specified min voltage]; Three bipolar: [ – specified max voltage, specified max voltage], [ – specified mid voltage, specified mid voltage], [ – specified min voltage, specified min voltage] (Voltage values to be specified, e.g., common values could be unipolar: 0 – 10V, 0 – 5V, 0 – 1V; bipolar: – 10V – 10V, – 5V – 5V, – 1V – 1V) |

| Current Output | 0 – 20 mA per channel |

| Output Update Rate | Up to 555 samples per second (S/s) |

| Isolation | Each channel is independently isolated |

| On – board Memory | EEPROM for storing calibration constants |

| Bus Interface | Controlled digitally over the SCXI bus |

| Power Requirements | Dependent on the overall SCXI system power supply; typically operates within the power budget of a standard SCXI chassis |

| Operating Temperature Range | – 10 °C to 55 °C |

| Physical Dimensions | Approximately [length value] cm x [width value] cm x [height value] cm (e.g., if typical SCXI module size, could be around 15 cm x 10 cm x 5 cm, but need to confirm actual values) |

| Weight | Approximately [weight value] kg (e.g., around 0.5 kg for a standard – sized SCXI module, but to be verified) |

| Software Compatibility | NI – DAQmx software; works in tandem with LabVIEW, LabWindows/CVI, and other NI – supported programming environments |

| Calibration Interval | Recommended 1 – year calibration interval to maintain accuracy |

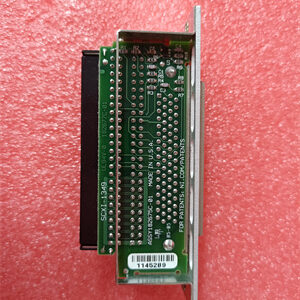

NI SCXI-1124

2. Product Introduction

The NI SCXI – 1124 is a specialized analog output module designed for use within the Signal Conditioning eXtensions for Instrumentation (SCXI) platform. It serves as a crucial component for applications that demand isolated, precise, and configurable analog output signals. This module is engineered to provide stable DC voltage or current outputs, making it suitable for a wide range of industrial, research, and test – and – measurement scenarios.

Equipped with six independent, isolated channels, each featuring a 12 – bit DAC, the SCXI – 1124 offers flexibility in output configuration. Users can select from multiple voltage ranges, both unipolar and bipolar, to match the requirements of their specific application. Additionally, the ability to output 0 – 20 mA of current per channel makes it compatible with a variety of current – driven devices. The software – configurable nature of the module, combined with its on – board EEPROM for calibration constant storage, simplifies the process of integrating it into existing systems and maintaining accurate output over time.

3. Core Advantages and Technical Highlights

Isolated Channels: Each of the six output channels on the SCXI – 1124 is independently isolated. This isolation feature is vital in applications where electrical interference between channels could affect the accuracy of the output signals. For example, in industrial control systems with multiple sensors and actuators, the isolation prevents crosstalk and ensures that each output channel operates independently and accurately.

Flexible Output Configuration: The ability to choose between multiple voltage ranges (both unipolar and bipolar) and output current up to 20 mA per channel makes the SCXI – 1124 highly adaptable. Engineers can easily configure the module to meet the specific requirements of their devices under test or control systems. This flexibility reduces the need for additional signal conditioning components, streamlining the overall system design.

On – board Calibration Storage: The on – board EEPROM stores calibration constants, which simplifies the calibration process. When recalibration is required, the module can quickly load the updated calibration values, ensuring consistent and accurate output. This feature is particularly beneficial in applications where long – term accuracy is critical, such as in precision measurement setups or industrial processes with tight tolerances.

SCXI Bus Compatibility: The SCXI – 1124 is digitally controlled over the SCXI bus. This allows for seamless integration with other SCXI modules in a system. A single DAQ device can control multiple SCXI – 1124 modules, enabling the expansion of the analog output capabilities as needed. The high – speed and reliable SCXI bus ensures fast data transfer and efficient operation, even in complex multi – module setups.

4. Typical Application Scenarios

Industrial Process Control: In manufacturing plants, the SCXI – 1124 can be used to control various process variables. For instance, it can output precise voltage or current signals to control the speed of motors, the position of actuators, or the flow rate of valves. The isolated channels ensure that the control signals are not affected by electrical noise in the industrial environment, maintaining the stability and accuracy of the process.

Sensor Emulation: In research and development or test – and – measurement applications, the SCXI – 1124 can be used to emulate sensor outputs. By generating accurate voltage or current signals that mimic real – world sensor readings, engineers can test the performance of data acquisition systems, control algorithms, or other components in a controlled environment. The flexibility of the output ranges allows for the emulation of a wide variety of sensors.

Environmental Monitoring Systems: In environmental monitoring applications, the SCXI – 1124 can be used to control actuators such as fans, pumps, or heaters. For example, it can output a control signal based on the data collected from environmental sensors (temperature, humidity, etc.) to adjust the operation of equipment and maintain optimal environmental conditions. The isolated channels protect the sensitive environmental sensors from electrical interference.

Medical Device Testing: In the medical device industry, the SCXI – 1124 can be used to test the response of medical equipment to specific input signals. For instance, it can generate voltage or current signals to simulate the electrical activity of the human body and test the functionality of devices such as electrocardiogram (ECG) monitors or defibrillators. The high – precision output and isolated channels are crucial for ensuring the accuracy and safety of the testing process.

NI SCXI-1124

5. Related Model Recommendations

SCXI – 1122: A 16 – channel isolated transducer multiplexer module that can be used in conjunction with the SCXI – 1124 in applications where multiple input channels need to be multiplexed and conditioned before being processed by the SCXI – 1124 for output. It provides an additional layer of signal conditioning for complex measurement setups.

SCXI – 1581: This module provides 32 channels of 100 mA current excitation. In applications where higher current excitation is required for sensors or other components, the SCXI – 1581 can be used alongside the SCXI – 1124. For example, in a system where sensors need both precise analog output control (from SCXI – 1124) and high – current excitation (from SCXI – 1581), the two modules can work together effectively.

NI – DAQmx Devices: Any NI – DAQmx – compatible data acquisition device can be used to control the SCXI – 1124. These devices provide the interface between the computer and the SCXI system, allowing for easy programming and data transfer. For example, the PCI – 6259 DAQ device can be used to control multiple SCXI – 1124 modules, providing high – speed data acquisition and control capabilities.

LabVIEW Software: LabVIEW is a powerful graphical programming environment from NI. It provides an intuitive interface for programming the SCXI – 1124, allowing engineers to easily configure the output channels, set calibration parameters, and integrate the module into larger measurement and control systems. With LabVIEW, complex control algorithms and data acquisition routines can be developed quickly and efficiently.

SCXI Chassis: A suitable SCXI chassis, such as the SCXI – 1000 or SCXI – 1042, is required to house the SCXI – 1124 and other SCXI modules. The chassis provides the mechanical support, power distribution, and bus connectivity for the modules, ensuring proper operation and reliable communication between components.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Ensure that the SCXI chassis is powered off before installation.

Use an anti – static wristband to prevent electrostatic discharge that could damage the module.

Verify that the SCXI chassis has an available slot compatible with the SCXI – 1124 module.

Check the power budget of the SCXI chassis to ensure it can support the additional power requirements of the SCXI – 1124.

Prepare the necessary cables for connecting the SCXI – 1124 to other components in the system, such as shielded cables for analog connections.

Install the latest version of the NI – DAQmx software on the host computer.

Commissioning Steps:

Insert the SCXI – 1124 module into the appropriate slot in the SCXI chassis and secure it using the provided screws.

Connect the necessary cables to the module, ensuring proper connection of analog output cables to the devices being controlled.

Power on the SCXI chassis and the host computer.

Launch the NI – DAQmx software on the host computer.

In the NI – DAQmx software, configure the SCXI – 1124 module. Set the output ranges, calibration constants (if not already stored in the on – board EEPROM), and any other relevant parameters.

Use the NI – DAQmx software to perform a self – test on the SCXI – 1124 module to ensure proper functionality.

Generate test signals from the SCXI – 1124 and verify that the output signals are accurate and within the expected range by measuring them with a calibrated multimeter or other appropriate measuring device.

Maintenance Suggestions:

Regularly inspect the cables connected to the SCXI – 1124 for any signs of damage, such as fraying or loose connections. Replace any damaged cables immediately.

Periodically clean the module and the SCXI chassis to remove dust and debris that could affect the performance of the module. Use a soft, dry cloth or compressed air (with caution to avoid electrostatic discharge) for cleaning.

Recalibrate the SCXI – 1124 module every year, or as recommended by NI, to maintain the accuracy of the output signals. Follow the calibration procedures provided in the NI – DAQmx software or the module’s documentation.

If there are any issues with the module, such as incorrect output signals or communication problems, check the NI – DAQmx software for error messages. Update the software to the latest version if necessary. Also, check for any hardware – related issues, such as loose connections or damaged components. If the problem persists, contact NI technical support for assistance.

7. Service and Guarantee Commitment

NI provides a standard warranty for the SCXI – 1124 module, typically covering a period of [warranty period, e.g., 1 year]. During this time, if the module is found to have defects in materials or workmanship, NI will repair or replace the module at no cost to the customer. This warranty ensures that customers can rely on the SCXI – 1124 for their critical applications without concerns about premature failure.

The company’s global technical support team is available to assist customers with any questions or issues related to the SCXI – 1124. Support is provided through multiple channels, including online resources, email, and phone. NI offers comprehensive documentation, including user manuals, programming guides, and application notes, to help customers get the most out of the module. For customers who require more in – depth assistance, NI also provides professional services for system integration and custom programming, ensuring that the SCXI – 1124 can be seamlessly integrated into complex measurement and control systems.