Description

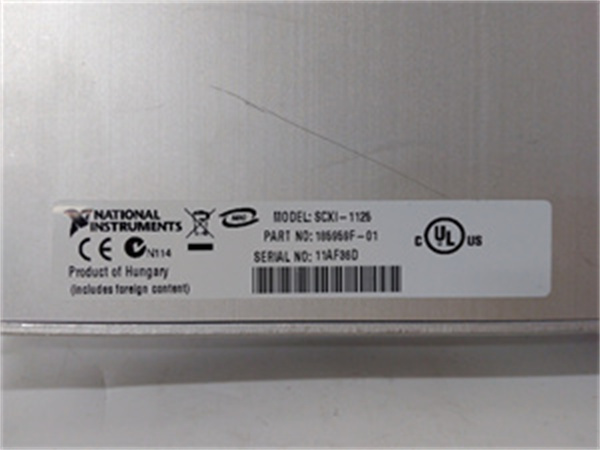

NI SCXI – 1125 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SCXI – 1125 |

| Manufacturer | NI |

| Product Category | 8 – Channel Isolated Analog Input Module |

| Number of Channels | 8 differential |

| Input Coupling | DC |

| Maximum Working Voltage | 300 VRMS between channels or channel to earth (isolation voltage) Signal inputs range from ±2.5 mV to ±300 V |

| Gain Ranges | 12 software – programmable gain settings |

| Filter | User – configurable automatic low – pass filter: 4 Hz or 10 kHz per channel |

| Sampling Rate | Not specified in a prominent way in the available sources, but designed for efficient multiplexing of 8 channels |

| I/O Connectors | Front: Connector type suitable for connection to terminal blocks Rear: Connection interface to the SCXI chassis for power and communication |

| Compatibility | SCXI chassis; works with terminal blocks like SCXI – 1320. Compatible with application development environments such as LabVIEW, LabWindows/CVI, Measurement Studio. Requires NI – DAQmx 9.0 (or later versions) driver software |

| Dimensions | 7.4 x 6.8 x 1.2 inches |

| Recommended Operating Temperature Range | General industrial temperature range suitable for indoor use, though specific values not in all sources |

| Storage Temperature Range | Not clearly specified in all sources, but expected to be within a reasonable range for electronic components |

| Humidity Range | Not clearly specified in all sources, but expected to be within non – condensing humidity levels suitable for electronics |

| Obsolete Status | Announced by NI, but still available for purchase and repairs from some sources |

| Part Number | 776572 – 25 |

NI SCXI-1125

Product Introduction

The NI SCXI – 1125 is an 8 – channel isolated analog input module designed for the SCXI system. It provides 300 VRMS of working isolation for each of its 8 analog input channels, making it a prime choice for applications where electrical isolation between sensors and the data acquisition (DAQ) system is crucial. This isolation helps protect the DAQ system from electrical transients, ground loops, and high – voltage surges, ensuring accurate signal acquisition even in electrically noisy or potentially hazardous environments.

Each channel of the SCXI – 1125 is equipped with programmable gain settings, allowing users to adapt to a wide variety of input signal levels. Whether dealing with small millivolt signals from delicate sensors or larger voltage signals, the appropriate gain can be easily configured. Additionally, each channel features an automatic low – pass filter that can be set to either 4 Hz or 10 kHz by the user. This filtering capability helps in reducing high – frequency noise, further enhancing the quality of the acquired signals. The module can multiplex its 8 channels into a single channel of a controlling DAQ device, and also allows for the addition of other modules to expand the overall channel count of the system.

Core Advantages and Technical Highlights

Exceptional Isolation Capabilities: The 300 VRMS working isolation per channel is a standout feature of the SCXI – 1125. This level of isolation provides a high degree of protection against electrical interference and potential damage to the DAQ system. In applications such as high – voltage testing, where large electrical currents and voltages are present, or in industrial settings with significant electromagnetic interference, the isolation offered by the SCXI – 1125 ensures that the sensor signals are accurately transmitted to the DAQ device without being affected by external electrical noise. It also protects the DAQ system from any voltage spikes or surges that may occur in the sensor circuits, reducing the risk of equipment failure and costly repairs.

Flexible Gain and Filter Settings: With 12 software – programmable gain settings, the SCXI – 1125 can be precisely adjusted to match the input signal levels. This flexibility is invaluable in applications where different sensors produce signals of varying magnitudes. For example, in a multi – sensor monitoring system, some sensors may output small millivolt – level signals, while others generate larger volt – level signals. The SCXI – 1125 can handle both types of signals effectively by setting the appropriate gain for each channel. The user – configurable low – pass filter, with options of 4 Hz or 10 kHz, allows for fine – tuning of the signal conditioning process. A 4 Hz filter is ideal for applications where very low – frequency noise needs to be removed, such as in precise temperature or strain measurements. On the other hand, a 10 kHz filter can be used when the signals contain higher – frequency components that need to be preserved while still reducing some of the high – frequency noise.

Programmable Offset Calibration: The SCXI – 1125 incorporates calibration hardware to eliminate error sources. With programmable offset calibration, software – programmable analog switches can ground the inputs of each of the instrumentation amplifiers for offset error calibration. A local EEPROM stores the calibration constants for each channel for each input range in a user – defined area. The EEPROM also stores a set of factory calibration constants in permanent memory, which cannot be altered. The NI – DAQ driver software directly utilizes these calibration constants to correct for gain and offset errors, ensuring accurate and reliable signal measurements over time. This calibration feature helps maintain the module’s performance and accuracy, even in the face of environmental changes or long – term use.

Parallel – Mode Operation and Irregular Scanning: The module offers parallel – mode operation, which expands its output capability. In parallel – mode, multiple channels can be read simultaneously, increasing the data acquisition speed for applications that require rapid monitoring of multiple signals. Additionally, the SCXI – 1125 supports irregular scanning, allowing users to select only the channels from which they need to acquire data and then scan those channels in any order. This feature is useful in applications where not all channels need to be monitored continuously or where specific channels are of more interest at different times. For example, in a complex industrial process, certain critical sensors may need to be monitored more frequently than others, and the irregular scanning feature of the SCXI – 1125 enables such selective and flexible data acquisition.

Typical Application Scenarios

High – Voltage and Noisy Industrial Environments: In industrial plants that deal with high – voltage equipment, such as power generation facilities, electric arc furnaces, or large – scale motor control centers, the SCXI – 1125 is extremely useful. It can be connected to sensors measuring parameters like temperature, pressure, and vibration in these high – voltage areas. The 300 VRMS isolation protects the DAQ system from the high – voltage transients and electrical noise present in these environments. For instance, in a power plant, the SCXI – 1125 can be used to monitor the temperature of transformers using thermocouples. The isolation ensures that any electrical interference from the high – voltage power lines does not affect the temperature measurements, providing accurate data for equipment health monitoring.

Medical Equipment Testing and Monitoring: In the medical field, during the testing and monitoring of certain medical equipment, electrical isolation is crucial to protect patients from electrical hazards. The SCXI – 1125 can be used to interface with sensors in medical devices such as patient monitors, defibrillators, and diagnostic equipment. For example, when measuring the electrical signals from a patient’s body using sensors in a patient monitor, the isolation provided by the SCXI – 1125 ensures that any electrical leakage or interference from the equipment does not harm the patient. The flexible gain and filter settings also allow for accurate signal conditioning of the delicate biological signals, enabling precise medical diagnosis and monitoring.

Research and Development in Electronics: In electronics research laboratories, when conducting experiments on new circuit designs or components, the SCXI – 1125 can be used to measure various electrical parameters. For example, when testing the performance of high – speed integrated circuits, the module can be connected to sensors that measure voltage, current, and temperature. The isolation feature protects the sensitive measurement equipment from any electrical back – feed or interference from the experimental circuits. The ability to perform irregular scanning is also beneficial in research, as researchers can focus on specific channels or signals of interest during different stages of the experiment, allowing for more targeted data collection and analysis.

NI SCXI-1125

Related Model Recommendations

NI SCXI – 1102: The SCXI – 1102 is a 32 – differential – channel voltage input module. While it has a much higher channel count compared to the SCXI – 1125, it lacks the isolation feature. If the application does not require electrical isolation and a higher number of channels is needed for monitoring multiple sensors simultaneously, the SCXI – 1102 would be a more suitable choice. It is also well – known for its high – accuracy thermocouple measurement capabilities, which may be more relevant in applications where precise temperature monitoring from a large number of thermocouples is required.

NI SCXI – 1140: This is a digital I/O module. If the application’s focus is on digital signal processing and control rather than analog input signal conditioning as in the case of the SCXI – 1125, the SCXI – 1140 would be the appropriate module. It can be used to interface with digital sensors, actuators, and other digital – based control systems. For example, in a robotic control system where digital signals are used to command the movement of robotic arms, the SCXI – 1140 can be used to handle these digital inputs and outputs, while the SCXI – 1125 would not be directly applicable.

NI SCXI – 1000 Chassis: As with other SCXI modules, the SCXI – 1000 chassis is an essential component when using the SCXI – 1125. It provides power and a communication backplane for the module. The SCXI – 1000 chassis allows for the integration of multiple SCXI modules, creating a comprehensive data acquisition or control system. When building an SCXI – based setup with the SCXI – 1125, the SCXI – 1000 chassis is a fundamental element to consider. It enables the proper installation and operation of the SCXI – 1125, along with other compatible modules, facilitating efficient data transfer and system control.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the SCXI – 1125, ensure that the SCXI chassis is properly set up and powered off to avoid electrical hazards. Gather the necessary tools, such as screwdrivers for any mechanical adjustments. Identify the appropriate slot in the SCXI chassis for the module installation. If using a terminal block like the SCXI – 1320, make sure it is also ready for connection. Familiarize yourself with the module’s user manual, which contains important information about jumper settings (if any), initial configuration, and safety precautions. Also, ensure that you have the correct version of the NI – DAQmx driver software installed on the host computer, as the SCXI – 1125 requires NI – DAQmx 9.0 or later versions for proper operation.

Commissioning: Insert the SCXI – 1125 into the designated slot in the SCXI chassis. Connect the appropriate cables between the module and the terminal block (if applicable) and the DAQ device, following the wiring diagrams provided in the manual. Use NI Measurement & Automation Explorer (MAX) to configure the hardware settings. Set the gain, filter, and other relevant parameters according to your application requirements. Power on the SCXI chassis and verify that the module is recognized by the system. Conduct initial tests by connecting known input signals, such as a precision voltage source within the specified input range, and check if the module is accurately acquiring and conditioning the signals using software like LabVIEW, LabWindows/CVI, or Measurement Studio, which are compatible with the SCXI – 1125.

Maintenance Suggestions: Regularly inspect the SCXI – 1125 for any signs of physical damage, such as cracks on the housing or loose connectors. Check the software – configured gain and filter settings to ensure they have not been accidentally changed. Since the module has calibration constants stored in its EEPROM, it is recommended to periodically verify the calibration using a high – precision calibration source. Although the factory calibration constants in the EEPROM’s permanent memory cannot be altered, the user – defined calibration constants may need to be updated over time, especially if the module is used in an environment with significant temperature or humidity variations. Use shielded cables for all connections to the module to minimize electromagnetic interference. Allow sufficient warm – up time (similar to other SCXI modules, at least 15 minutes) before taking measurements to ensure stable operating conditions.

Service and Guarantee Commitment

Although NI has announced the obsolete status of the SCXI – 1125, some sources still offer it for purchase and repairs. While NI’s standard warranty coverage may be limited due to its obsolete status, some third – party suppliers may provide their own warranties. Technical support may still be available through NI’s official channels, including online resources and user forums. However, for in – depth support, users may need to rely on third – party service providers. In case of any issues, users can refer to the NI documentation available at ni.com/manuals, which includes the SCXI – 1125 user manual and calibration procedure documents. If the module is found to be defective within the warranty period (if applicable), contact the supplier for repair or replacement options. It is important to note that as the module is obsolete, the availability of replacement parts may become limited over time, so proper maintenance and early detection of issues are crucial.