Description

Product Overview

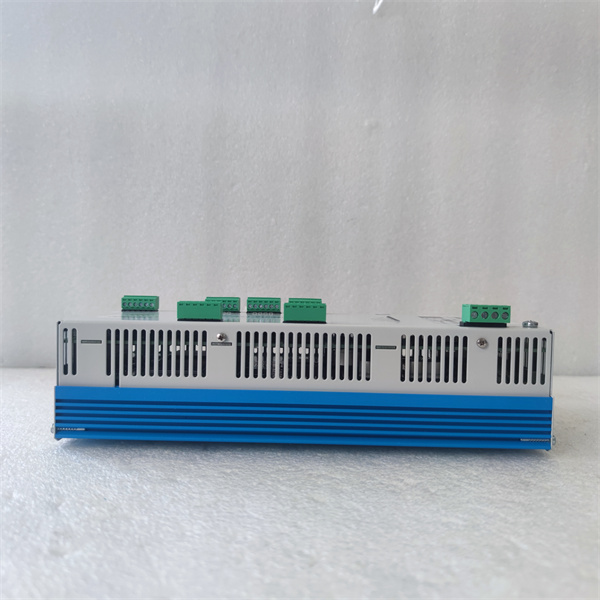

The Saacke FSC-01 is likely a specialized industrial product within Saacke’s product portfolio. Saacke, a company known for its expertise in industrial solutions, especially in areas related to combustion, heating, and energy systems, has presumably engineered the FSC-01 to meet specific industry needs. This product might serve as a key component in control systems, monitoring devices, or as part of a combustion – related assembly, playing a crucial role in ensuring the efficient and safe operation of industrial processes, particularly those involving heating, power generation, or energy management.

Built with Saacke’s technical know – how and engineering experience, the FSC-01 is expected to offer reliable performance, durability, and compatibility with other Saacke products or relevant industrial equipment. It could be tasked with functions such as regulating combustion parameters, monitoring system performance, or facilitating the smooth interaction between different parts of an industrial system. Whether used in large – scale power plants, industrial boilers, or smaller – scale heating systems, the Saacke FSC-01 is designed to enhance system efficiency, reduce energy consumption, and contribute to the overall reliability of industrial operations in its applicable fields.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | FSC-01 |

| Manufacturer | Saacke |

| Product Type | [Likely a Combustion Control Module, Sensor Controller, or a Heating System Component] |

| Input Voltage Range | [Estimated: 24 VDC – 240 VAC, depending on the actual application] |

| Output Signals | [Possible: Analog (4 – 20 mA, 0 – 10 V), Digital (Relay outputs, Pulse signals)] |

| Control Accuracy | [Estimated: ±1% for critical parameters, if it’s a control – related device] |

| Operating Temperature Range | -10°C – 60°C |

| Protection Class | [Estimated: IP20 for indoor use, or IP65 if designed for harsher environments] |

| Dimensions | [Estimated: 150mm × 100mm × 70mm, subject to actual product form] |

| Weight | [Estimated: 1 – 3 kg] |

| Communication Protocols (if applicable) | [Possible: Modbus RTU, Profibus, or a proprietary Saacke protocol] |

| Sensor Compatibility | [Expected to be compatible with a range of combustion – related sensors, such as oxygen sensors, temperature sensors] |

SAACKE FSC-01

Main Features and Advantages

Precise Control and Monitoring

If the Saacke FSC-01 is a combustion control module or sensor controller, it likely offers precise control and monitoring capabilities. For example, in a combustion system, it can accurately regulate parameters such as fuel – air ratio, flame stability, and combustion temperature. This precision ensures optimal combustion efficiency, reducing fuel consumption and minimizing harmful emissions. By continuously monitoring key system parameters, it can detect any deviations from the set values in real – time and make immediate adjustments, preventing potential operational issues and ensuring the safe and stable operation of the system.

Robust and Reliable Design

Built to withstand the rigors of industrial environments, the Saacke FSC-01 features a robust and reliable design. Its wide operating temperature range and appropriate protection class enable it to operate effectively in various conditions, including dusty, humid, or vibration – prone environments. High – quality components and strict manufacturing standards contribute to its long service life, reducing the risk of component failure and minimizing downtime. This reliability is crucial for industries where continuous operation is essential, such as power generation and industrial heating, as any disruption can lead to significant losses.

Easy Integration and Compatibility

The Saacke FSC-01 is likely designed for easy integration into existing industrial systems. It may support common communication protocols, allowing it to communicate seamlessly with other Saacke products, such as burners, boilers, and control panels, as well as third – party equipment. This compatibility simplifies the process of upgrading or expanding industrial systems, enabling users to incorporate the FSC-01 without major overhauls. Whether it’s replacing an older component or adding new functionality to a system, the FSC-01 can be integrated with relative ease, saving time and resources during installation and commissioning.

User – Friendly Operation

The Saacke FSC-01 probably features a user – friendly design for ease of operation. It may have an intuitive interface, such as a digital display and simple control buttons, which allows operators to easily configure settings, monitor system status, and perform basic troubleshooting. Clear labeling and straightforward instructions make it accessible even to users with limited technical expertise. Additionally, Saacke may provide comprehensive documentation and technical support, ensuring that users can effectively utilize the product and address any issues that may arise during operation.

SAACKE FSC-01

Application Field

The Saacke FSC-01 can be applied in several industries. In the power generation industry, it can be used in coal – fired, gas – fired, or biomass – fired power plants. As a combustion control module, it optimizes the combustion process in boilers, improving energy conversion efficiency and reducing emissions. This helps power plants meet environmental regulations while maximizing power output.

In the industrial heating sector, the FSC-01 can be installed in industrial boilers used for processes such as steam generation, space heating, or process heating. It monitors and controls the heating system to ensure consistent and efficient heat supply, which is essential for maintaining the quality of industrial processes, such as in food processing, chemical manufacturing, and textile production.

In the commercial building sector, the Saacke FSC-01 can be part of large – scale heating, ventilation, and air – conditioning (HVAC) systems. It can control the operation of boilers or furnaces, optimizing energy consumption and ensuring comfortable indoor environments. Its ability to precisely regulate temperature and other parameters helps buildings reduce energy costs and achieve better environmental performance.

Related Products

- Saacke FSC-02: Potentially an upgraded version of the FSC-01, with enhanced features such as more advanced control algorithms, additional communication interfaces, or improved accuracy. It could be designed for more complex industrial applications that require higher – performance control and monitoring.

- Saacke FSC-01 – A: A variant with modified features, perhaps optimized for a specific industry like the food industry. It might include additional safety features, such as enhanced flame monitoring for food processing applications where fire safety is of utmost importance.

- Saacke FSC-01 – B: This version could have a different physical form factor or mounting option, making it more suitable for installation in compact or space – constrained environments, such as small – scale industrial boilers or rooftop HVAC units.

- Saacke FSC-00: A basic version of the FSC-01, with fewer functions and a lower price point. It may be suitable for smaller – scale applications or for customers who require a more cost – effective solution for basic control and monitoring tasks.

- Saacke FSC-01 – S: A specialized model, possibly designed for high – efficiency combustion systems. It might feature advanced sensor integration and real – time data analysis capabilities to further optimize combustion efficiency and reduce emissions.

Installation and Maintenance

Pre – installation preparation: Before installing the Saacke FSC-01, carefully review the product manual to understand the specific installation requirements. Ensure that the installation environment meets the specified temperature, humidity, and electrical conditions. If it is a communication – related device, verify the compatibility of its communication protocols with other components in the system. For a control module, check the compatibility with the sensors and actuators it will be connected to. Prepare all necessary tools and mounting hardware, and ensure that the mounting surface is clean, flat, and properly grounded. Connect the power cables, communication cables, and sensor/actuator cables according to the provided wiring diagrams, ensuring all connections are secure and correctly wired.

Maintenance recommendations: Regularly inspect the Saacke FSC-01 for any signs of abnormal operation, such as unusual noises, overheating, or error indicators. Check the tightness of all cable connections and the integrity of the communication interfaces. Clean the exterior of the product periodically to remove dust and debris, especially if it is installed in a dusty environment. Periodically calibrate the sensors connected to the FSC-01 to ensure accurate measurement and control. Update the device’s firmware (if applicable) to benefit from the latest features, performance improvements, and security patches. In case of a malfunction, refer to the product manual for troubleshooting steps or contact Saacke’s technical support team for professional assistance. Keep detailed records of all maintenance activities, including inspection dates, component replacements, and any issues resolved, for future reference.

Product Guarantee

Saacke stands firmly behind the quality of the Saacke FSC-01. The product undergoes strict quality control procedures during manufacturing to meet the highest industry standards. Saacke typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, Saacke will provide free repair or replacement services. Additionally, their professional technical support team is available to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the FSC-01 with confidence, maximizing the value and reliability of their industrial systems.