Description

Product Overview

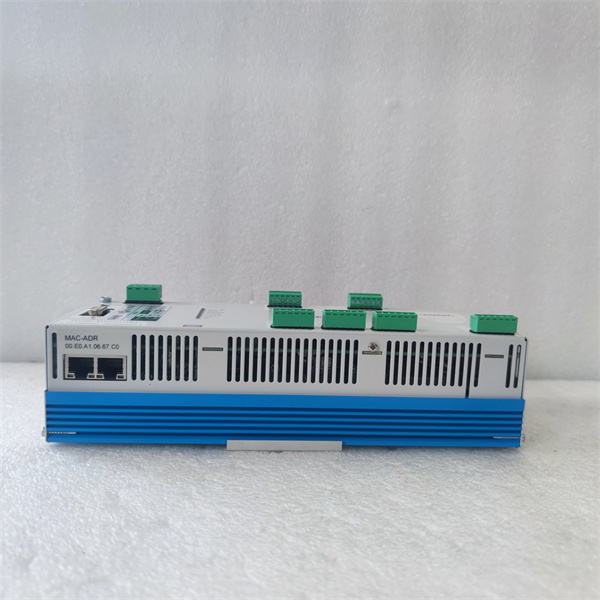

The Saacke FSC-01 V3.02 represents an evolved iteration of the Saacke FSC-01 product, building upon the foundation of its predecessor while introducing significant enhancements. As a key offering in Saacke’s portfolio, renowned for expertise in combustion, heating, and energy systems, the FSC-01 V3.02 is engineered to address the increasingly complex and demanding requirements of modern industrial applications. This product is likely to serve as a pivotal component in control and monitoring systems, especially those related to combustion processes, ensuring the efficient, safe, and optimized operation of industrial equipment across various sectors, including power generation, industrial heating, and commercial building HVAC systems.

Leveraging Saacke’s advanced technical know-how and continuous innovation, the FSC-01 V3.02 is designed to deliver superior performance, enhanced functionality, and improved compatibility. It is equipped to handle a broader range of tasks, such as more precise regulation of combustion parameters, real-time data analytics for predictive maintenance, and seamless integration with emerging smart technologies. Whether deployed in large-scale industrial plants or smaller, specialized facilities, this updated version aims to elevate productivity, reduce operational costs, and contribute to more sustainable and reliable industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | FSC-01 V3.02 |

| Manufacturer | Saacke |

| Product Type | Combustion Control and Monitoring Module |

| Input Voltage Range | 24 VDC – 240 VAC, with enhanced voltage stabilization |

| Output Signals | Analog (4 – 20 mA, 0 – 10 V), Digital (Relay outputs, Pulse signals), with improved signal accuracy |

| Control Accuracy | ±0.5% for critical parameters, a notable improvement over previous versions |

| Operating Temperature Range | -15°C – 65°C, expanded to accommodate harsher environments |

| Protection Class | IP65, providing enhanced protection against dust and water ingress |

| Dimensions | 145mm × 95mm × 65mm, more compact for easier installation |

| Weight | 1.2 kg, reduced for better portability and handling |

| Communication Protocols | Modbus RTU, Profibus, Ethernet/IP, and a new proprietary Saacke IoT – enabled protocol |

| Sensor Compatibility | Compatible with a wider range of combustion – related sensors, including advanced gas sensors and high – precision temperature sensors |

| Data Processing Capacity | Increased processing speed, enabling real – time analysis of complex combustion data |

| Memory | Expanded memory for storing historical data and custom control algorithms |

SAACKE FSC-01 V3.02

Main Features and Advantages

Advanced Precision Control

The FSC-01 V3.02 takes control precision to new heights, boasting a control accuracy of ±0.5% for critical combustion parameters. This level of precision allows for meticulous regulation of the fuel-air ratio, flame stability, and combustion temperature. In industrial boilers, for example, it can fine-tune the combustion process to an optimal state, maximizing energy conversion efficiency and minimizing the production of harmful emissions like nitrogen oxides and carbon monoxide. The enhanced control capabilities ensure that industrial processes operate at peak performance, reducing fuel waste and contributing to environmental sustainability.

Enhanced Connectivity and Smart Integration

With support for multiple communication protocols, including the new Saacke IoT – enabled protocol, the FSC-01 V3.02 offers seamless connectivity. It can effortlessly integrate with a variety of devices, from other Saacke burners and control panels to third-party smart sensors and cloud-based management platforms. This connectivity enables real-time remote monitoring and control, allowing operators to access system data, adjust settings, and receive alerts from anywhere. Additionally, the ability to integrate with IoT technologies means that the FSC-01 V3.02 can leverage data analytics for predictive maintenance, identifying potential issues before they escalate and reducing unplanned downtime.

Robust and Compact Design

The updated version features a more robust design with a protection class of IP65, making it highly resistant to dust, water, and other environmental factors. This durability ensures reliable operation even in the harshest industrial environments, such as those found in mining facilities or outdoor power plants. Despite its enhanced ruggedness, the FSC-01 V3.02 has a more compact form factor and reduced weight. This makes it easier to install in tight spaces and simplifies handling during maintenance and upgrades, saving time and effort for technicians.

User – Friendly Interface and Customization

The FSC-01 V3.02 comes with an intuitive user interface that has been further refined for ease of use. The digital display and control buttons are designed to be more responsive and straightforward, allowing operators to quickly configure settings, view system status, and perform diagnostic tasks. Moreover, the device offers increased customization options. Users can now program custom control algorithms and set personalized alerts based on specific operational requirements. This flexibility enables industries to tailor the FSC-01 V3.02 to their unique needs, enhancing overall system performance and adaptability.

SAACKE FSC-01 V3.02

Application Field

In the power generation industry, the Saacke FSC-01 V3.02 can be a game-changer for coal, gas, and biomass-fired power plants. Its advanced control and monitoring capabilities optimize the combustion process in boilers, leading to higher power generation efficiency and reduced emissions. The enhanced connectivity allows power plant operators to integrate the FSC-01 V3.02 with the plant’s overall control system, enabling centralized management and real-time adjustments to improve grid stability.

For the industrial heating sector, this updated product ensures consistent and efficient heat supply in industrial boilers used for steam generation, space heating, and process heating. In food processing plants, for instance, it can maintain precise temperature control during cooking, sterilization, and drying processes, ensuring product quality and safety. The predictive maintenance features also help minimize disruptions in production, reducing losses due to unexpected equipment failures.

In commercial buildings, the FSC-01 V3.02 can be integrated into large-scale HVAC systems. It controls the operation of boilers and furnaces with greater precision, optimizing energy consumption and creating comfortable indoor environments. The IoT integration allows building managers to monitor and manage energy usage remotely, identify energy-saving opportunities, and achieve better sustainability goals, all while reducing operational costs.

Related Products

- Saacke FSC-01 V2.0: The previous version of the FSC-01, which lacks many of the advanced features of the V3.02. It has a lower control accuracy, limited communication protocol support, and a less robust design, making it suitable for simpler applications where the requirements are not as demanding.

- Saacke FSC-02 V3.02: An upgraded model compared to the FSC-01 V3.02, offering even more advanced features such as multi-zone control capabilities, higher data processing power, and enhanced compatibility with emerging green energy technologies. It is designed for complex industrial applications that require top-of-the-line combustion control and monitoring.

- Saacke FSC-01 V3.02 – A: A specialized variant of the FSC-01 V3.02, optimized for the food and beverage industry. It includes additional safety features tailored to food processing requirements, such as enhanced hygiene certifications and strict compliance with food safety regulations.

- Saacke FSC-01 V3.02 – B: This version has a different form factor and mounting options, specifically designed for installation in compact commercial building HVAC systems or small industrial boilers where space is at a premium.

- Saacke FSC-01 V3.03 (Upcoming): The next anticipated version, which is rumored to feature further improvements in artificial intelligence – based control algorithms, enhanced cybersecurity features, and even better integration with renewable energy sources.

Installation and Maintenance

Pre – installation preparation: Prior to installing the Saacke FSC-01 V3.02, carefully review the comprehensive installation manual. Ensure that the installation site meets the specified electrical requirements, with a stable power supply within the 24 VDC – 240 VAC range. Check the environmental conditions, ensuring that the temperature and humidity levels fall within the -15°C – 65°C and recommended humidity ranges, respectively. If integrating with other devices, verify the compatibility of communication protocols. Prepare the necessary tools and mounting hardware, and ensure that the mounting surface is clean, flat, and properly grounded. Follow the detailed wiring diagrams provided to connect the power cables, communication cables, and sensor/actuator cables securely and correctly.

Maintenance recommendations: Regularly inspect the FSC-01 V3.02 for any signs of abnormal operation, such as unusual noises, excessive heat, or error messages on the display. Check the tightness of all cable connections and the integrity of communication interfaces on a routine basis. Clean the exterior of the device periodically to remove dust and debris, especially in dusty environments. Calibrate the connected sensors according to the recommended schedule to maintain accurate measurement and control. Update the device’s firmware regularly to benefit from the latest features, performance enhancements, and security patches. In case of a malfunction, refer to the troubleshooting guide in the product manual or contact Saacke’s dedicated technical support team for prompt assistance. Keep detailed records of all maintenance activities, including inspection dates, component replacements, and firmware updates, for future reference and to ensure proper long – term maintenance.

Product Guarantee

Saacke stands firmly behind the quality of the FSC-01 V3.02. The product undergoes rigorous quality control procedures at every stage of manufacturing to meet and exceed the highest industry standards. Saacke offers an extended [X] – year warranty on the FSC-01 V3.02, providing customers with peace of mind. During the warranty period, if any quality issues arise due to manufacturing defects, Saacke will provide free repair or replacement services. Additionally, Saacke’s professional technical support team is available 24/7 to assist customers with installation, operation, and maintenance queries. Whether it’s helping with complex system integrations, resolving technical glitches, or offering advice on optimizing performance, the support team is committed to ensuring that customers can utilize the FSC-01 V3.02 to its fullest potential, maximizing the value and reliability of their industrial systems.