Description

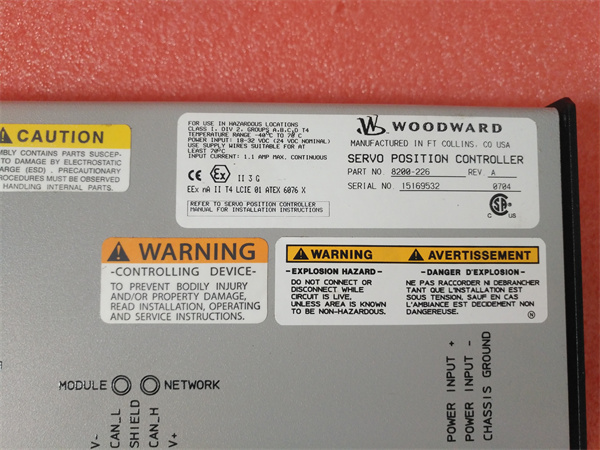

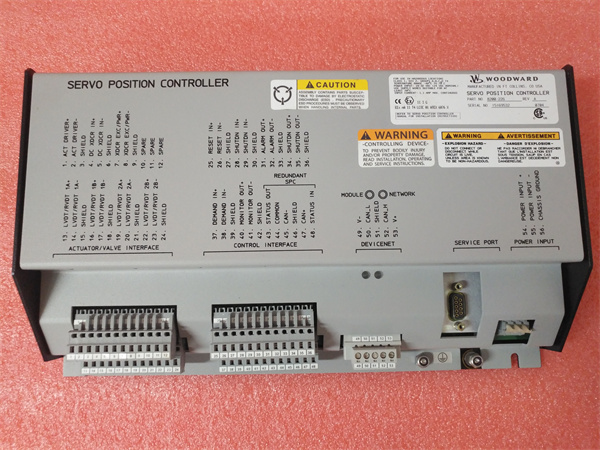

Woodward 8200-226 Servo Position Controller (SPC)

1. Product Description

The Woodward 8200-226 is a high-precision servo position controller (SPC) designed to drive hydraulic or pneumatic servo valves in industrial applications. As the latest iteration in Woodward’s SPC series, it replaces older models like the 8200-224 and 8200-225, offering enhanced performance and compatibility. The 8200-226 accepts position commands via DeviceNet communication or 4–20 mA analog signals, enabling seamless integration with control systems. Its dual-channel architecture supports redundant feedback from AC/DC devices, ensuring reliable operation in critical environments. With Windows-based configuration software and advanced features like position loop filtering, the 8200-226 optimizes actuator positioning for turbines, compressors, and other machinery requiring precise motion control.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC (18–32 VDC) |

| Current Range | ±10 to ±250 mA |

| Input Impedance | 200 Ω |

| Position Demand Signals | DeviceNet or 4–20 mA |

| Resolution | 11 bits |

| Power Dissipation | 20 W typical heat load |

| Operating Temperature | -40°C to +85°C |

| Weight | 1.55 kg |

| Dimensions | 32.9 cm × 20.3 cm × 6.5 cm |

3. Advantages and Features

- Precision Control: Supports proportional and integrating servo valves with ±0.1% positioning accuracy.

- Flexible Connectivity: Dual-channel feedback processing for AC/DC devices and optional DeviceNet integration.

- User-Friendly Configuration: Windows-based software for calibration, monitoring, and troubleshooting.

- Wide Environmental Range: Operates in extreme temperatures (-40°C to +85°C) and meets CE, UL/cUL, and RoHS standards.

- Reliability: Redundant design minimizes downtime, with a 12-month warranty and 15+ year service life.

4. Application Areas and Case Studies

- Power Generation: Controls steam/gas turbine actuators in power plants.

- Oil and Gas: Manages valves in pipelines and refineries.

- Industrial Machinery: Optimizes motion control for pumps, compressors, and conveyors.

Case Study:

A European energy plant reduced turbine actuator response time by 30% using the 8200-226, improving system efficiency and reducing maintenance costs by 20%.

A European energy plant reduced turbine actuator response time by 30% using the 8200-226, improving system efficiency and reducing maintenance costs by 20%.

5. Competitor Comparison

Compared to similar SPCs:

- Higher Temperature Tolerance: Operates at +85°C vs. typical +70°C limits.

- Dual-Channel Redundancy: Optional redundant configuration for mission-critical systems.

- Faster Commissioning: Plug-and-play compatibility with legacy Woodward systems.

6. Selection Recommendations

- Input Type: Choose DeviceNet or 4–20 mA based on existing control infrastructure.

- Environmental Needs: Opt for the 8200-226 for applications requiring extreme temperature resilience.

- Redundancy: Enable dual-channel feedback for systems where downtime is costly.

7. Precautions

- Installation: Follow Woodward’s guidelines for proper wiring and grounding to prevent EMI.

- Software Updates: Regularly update firmware via the SPC Service Tool (latest version: 3.2.1).

- Load Management: Avoid exceeding the 250 mA output current to prevent overheating.

- Storage: Store at -40°C to +221°F in dry conditions.

声明

山西鑫业达国际贸易有限公司 is your trusted partner for Woodward 8200-226 and automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.

山西鑫业达国际贸易有限公司 is your trusted partner for Woodward 8200-226 and automation solutions. Visit www.xydcontrol.com or contact us for sales and technical support.