Description

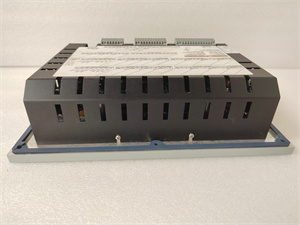

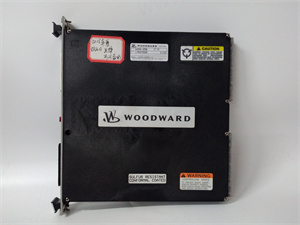

WOODWARD 9907-164 Turbine Governor Controller

1.Product Description

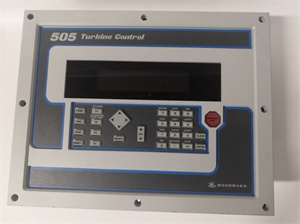

The WOODWARD 9907-164 is a high-performance turbine governor controller designed for industrial applications,specifically tailored for steam turbines,turbogenerators,and turbine expanders.As part of the renowned 505/505E microprocessor-based governor series,the 9907-164 offers precise control over turbine speed,load,and critical operational parameters.Its intuitive interface and field-configurable features make it a versatile solution for optimizing energy efficiency and system reliability in power generation,oil and gas,and industrial processes.

Key functions include adaptive speed regulation,auto-start sequences,critical speed avoidance,and real-time diagnostics.The controller supports single or dual split-stage actuators to manage steam inlet valves,ensuring smooth operation under varying load conditions.

2.Technical Specifications

Parameter Specification

Input Voltage+24 VDC(18–36 VDC range)

Operating Temperature–4°F to+140°F(–20°C to+60°C)

Storage Temperature–40°F to+185°F(–40°C to+85°C)

Display 2-line x 24-character LCD

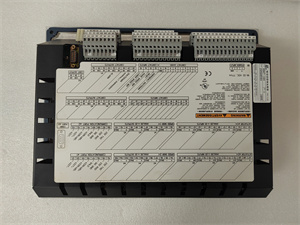

Inputs 16 discrete contacts(4 dedicated,12 programmable),6 analog(4–20 mA)

Communication RS-232/RS-422 with Modbus protocol

Weight 9.11 lbs(4.13 kg)

3.Advantages and Features

Field Configurability:The 9907-164 allows on-site operators to adjust settings via its menu-driven interface,reducing downtime and enhancing flexibility.

Critical Speed Avoidance:Built-in algorithms automatically bypass resonance frequencies,preventing mechanical stress and extending turbine lifespan.

Fault Detection:First-out shutdown indicators and self-diagnostics quickly identify issues,minimizing maintenance costs.

Energy Efficiency:Precise control of steam inlet valves optimizes fuel consumption,contributing to up to 15%energy savings in industrial processes.

4.Application Areas and Case Studies

Industries:

Power generation(steam/gas turbines)

Oil and gas(turbine-driven compressors)

Manufacturing(process control systems)

Case Study:

A European power plant integrated the WOODWARD 9907-164 into its steam turbine system.The controller’s adaptive PID tuning reduced load fluctuations by 20%,improving grid stability and extending turbine component life by 30%.

5.Competitor Comparison

Compared to standard turbine controllers,the 9907-164 offers:

Enhanced I/O Capacity:16 discrete inputs(vs.typical 8–12)for complex control scenarios.

Wide Temperature Range:Operates reliably in extreme conditions,outperforming competitors limited to+120°F.

Modbus Compatibility:Seamless integration with third-party systems,unlike proprietary solutions requiring custom interfaces.

6.Selection Recommendations

Compatibility:Verify compatibility with existing turbine actuators and communication protocols.

Environment:Ensure operating temperatures align with site conditions(e.g.,–4°F for outdoor installations).

Budget:Consider optional features like remote monitoring for long-term cost savings.

7.Installation and Maintenance Notes

Wiring:Use shielded cables to prevent EMI interference.

Power Stability:Maintain a clean power supply to avoid voltage spikes.

Calibration:Schedule annual checks to ensure accurate sensor readings.

Shanxi Xinyeda International Trade Co.,Ltd.is your trusted partner for WOODWARD 9907-164 and other automation spare parts.Visit www.xydcontrol.com or contact us for sales and technical support.