Description

Product Specification: Yaskawa JANCD-MIO03 IO-Link Master Module

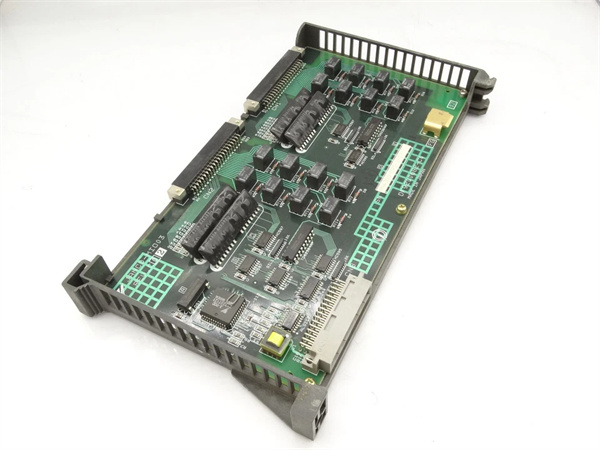

The Yaskawa JANCD-MIO03 is a high-performance IO-Link master module designed for industrial automation systems, optimized for seamless integration with Yaskawa robotic and motion control platforms. This module enables efficient communication between field devices and higher-level controllers, ensuring reliable data exchange and enhanced system flexibility.

1. Product Description

The JANCD-MIO03 serves as a bridge between IO-Link devices (e.g., sensors, actuators) and industrial networks like PROFINET or EtherNet/IP. Key features include:

- Dual-Functionality: Combines IO-Link master capabilities with high-current power supply support.

- Robust Design: IP69K-rated for resistance to dust, water, and extreme temperatures (-40°C to +70°C).

- High-Current Output: Provides up to 16A total power (4A per port) for driving heavy-duty devices like grippers or valves.

- Modular Expansion: Supports up to 16 digital I/O channels via configurable ports.

- Advanced Protocols: Integrates with Yaskawa’s motion controllers and third-party PLCs using standard industrial protocols.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24V DC ±10% |

| Output Power | 16A total (4A per port) |

| Communication Interfaces | IO-Link v1.1, PROFINET, EtherNet/IP |

| 防护等级 | IP69K |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 120 mm × 60 mm × 40 mm |

3. Advantages and Features

- Reliability in Harsh Environments: IP69K rating ensures durability in washdown, dusty, or high-temperature settings.

- Cost-Effective Power Delivery: Direct high-current supply eliminates the need for external power modules.

- Simplified Integration: Supports SIDI (System-Integrated Device Information) for automatic device parameterization.

- Local Control Capability: Embedded ARGEE logic for edge computing and decentralized automation.

4. Application Areas and Cases

- Automotive Manufacturing: Controls robotic grippers and welding tools in assembly lines.

- Food and Beverage: Manages sensors and valves in hygienic production environments.

- Case Study: A logistics hub reduced downtime by 15% using JANCD-MIO03 to monitor conveyor belt sensors and actuators in a 24/7 operation.

5. Competitor Comparison

The JANCD-MIO03 stands out with:

- Integrated Power Supply: Eliminates external power units, reducing cabling and costs.

- Wide Temperature Range: Outperforms standard modules in extreme climates.

- Yaskawa Ecosystem Compatibility: Optimized for seamless interaction with Yaskawa robots and controllers.

6. Selection Recommendations

- High-Power Applications: Choose the JANCD-MIO03 if your system requires more than 2A per IO-Link port.

- Harsh Environments: Prioritize this module for outdoor or washdown scenarios.

- Protocol Flexibility: Ideal for systems needing PROFINET or EtherNet/IP integration alongside IO-Link.

7. Precautions

-

ESD Protection: Use anti-static equipment during installation.

-

Power Management: Ensure the power supply meets the total current requirements (16A max).

-

Firmware Updates: Regularly update firmware for compatibility with new IO-Link devices.

-

Cable Selection: Use shielded cables to prevent signal interference in noisy environments.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner for [Yaskawa JANCD-MIO03] and other industrial automation spare parts. Visit our website www.xydcontrol.com or contact us for sales and technical support.