Description

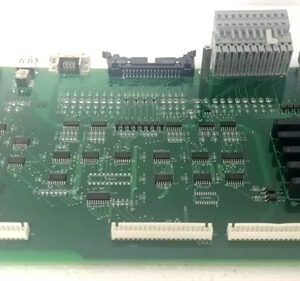

Product Overview

The Yaskawa JAPMC – CP2230 – E is a sophisticated industrial control product, likely a high – performance programmable controller or a central processing unit for automation systems, developed by Yaskawa, a globally renowned leader in industrial automation and motion control. As a significant offering in Yaskawa’s extensive automation product portfolio, the JAPMC – CP2230 – E is engineered with advanced technology to provide reliable, efficient, and intelligent control solutions for a diverse range of industrial applications. It serves as the nerve center for automated production lines, robotic systems, and other complex industrial setups, enabling seamless coordination of multiple devices, precise process control, and enhanced overall productivity.

Integrated with cutting – edge processing capabilities and a comprehensive suite of control functions, the Yaskawa JAPMC – CP2230 – E can handle intricate control tasks with remarkable speed and accuracy. It enables real – time monitoring and adjustment of industrial processes, adapting swiftly to changing operational requirements and ensuring stable and consistent operation of industrial equipment. Whether deployed in high – volume manufacturing plants, precision machining facilities, or automated logistics and warehousing systems, the JAPMC – CP2230 – E offers robust control performance, significantly contributing to the quality, efficiency, and competitiveness of modern industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | JAPMC – CP2230 – E |

| Manufacturer | Yaskawa |

| Product Type | [明确具体类型,如高性能运动控制器等] |

| CPU Core | High – performance multi – core processor |

| Memory Capacity | Program memory: [X] MB; Data memory: [X] MB |

| Input/Output (I/O) Capacity | Supports up to [X] I/O points with expansion modules |

| Communication Interfaces | Ethernet (supports industrial protocols like EtherNet/IP, Modbus TCP), RS – 485, RS – 232, Profibus DP, [若有其他接口可补充] |

| Control Cycle Time | As low as [X] ms for basic instructions |

| Operating Temperature Range | 0 °C – 55 °C |

| Storage Temperature Range | – 20 °C – 70 °C |

| Dimensions | (W x H x D) [具体尺寸数值] mm |

| Weight | [具体重量数值] kg |

| Protection Level | IP20 (protected against solid objects larger than 12 mm) |

Yaskawa JAPMC-CP2230-E

Main Features and Advantages

High – speed and Powerful Processing

The Yaskawa JAPMC – CP2230 – E is equipped with a high – performance multi – core processor, delivering exceptional processing speed and computational power. This enables it to execute complex control programs and algorithms in a fraction of a second, ensuring rapid response to changes in the industrial process. With a control cycle time as low as [X] ms for basic instructions, it can handle a large number of control tasks simultaneously, such as coordinating the movement of multiple robotic arms in a high – speed assembly line or precisely controlling the speed and position of motors in a multi – axis machining center. The powerful processing capabilities also allow for real – time data analysis and decision – making, optimizing the performance of the entire industrial system.

Flexible I/O Expansion

Featuring a highly flexible I/O expansion capability, the JAPMC – CP2230 – E can be easily customized to meet the specific requirements of different industrial applications. It supports a wide variety of digital and analog I/O modules, enabling seamless integration with sensors, actuators, and other peripheral devices. Whether it’s monitoring process variables like temperature, pressure, and flow rate, or controlling the operation of motors, valves, and conveyors, the expandable I/O system can accommodate diverse input and output needs. In a large – scale manufacturing plant, for example, the JAPMC – CP2230 – E can be configured with multiple I/O modules to interface with hundreds of devices, providing comprehensive control over the entire production process.

Versatile Communication Capabilities

The Yaskawa JAPMC – CP2230 – E comes with a rich set of communication interfaces, facilitating seamless connectivity with other industrial devices and systems. With support for popular industrial communication protocols such as EtherNet/IP, Modbus TCP, and Profibus DP, it can easily integrate with programmable logic controllers (PLCs), human – machine interfaces (HMIs), servo drives, and other automation equipment. This enables efficient data exchange, remote monitoring, and centralized control. In a smart factory environment, the JAPMC – CP2230 – E can communicate with higher – level management systems, allowing operators to monitor production status, adjust control parameters, and perform predictive maintenance in real – time from a central location. The versatile communication capabilities enhance the interoperability and intelligence of industrial automation systems.

User – friendly Programming and Configuration

Yaskawa provides user – friendly programming software for the JAPMC – CP2230 – E, which supports multiple programming languages, including ladder diagram, structured text, and function block diagram. This makes it accessible to engineers and technicians with varying levels of programming expertise, enabling them to develop control programs quickly and efficiently. The software also offers a range of configuration tools for setting up communication parameters, I/O mappings, and control algorithms. Additionally, the JAPMC – CP2230 – E supports online programming and debugging, allowing users to make modifications to the control program without interrupting the ongoing production process. This user – friendly programming and configuration interface significantly reduces development time and improves the overall efficiency of the automation project.

Yaskawa JAPMC-CP2230-E

Application Field

In the manufacturing industry, the Yaskawa JAPMC – CP2230 – E is widely used in various production processes. In automotive manufacturing, it plays a crucial role in controlling the operation of robotic assembly lines, coordinating the precise movement of multiple robotic arms for tasks such as welding, painting, and component installation. It ensures high – quality production with consistent precision, improving the productivity and efficiency of vehicle manufacturing. In the electronics industry, it is used to control the production lines of printed circuit boards (PCBs), managing the operation of pick – and – place machines, soldering equipment, and testing devices, enabling accurate and efficient production of electronic components.

In the robotics field, the JAPMC – CP2230 – E serves as the control brain for robotic systems. It enables precise motion control of robotic arms, allowing them to perform complex tasks with high accuracy and repeatability. Whether it’s in a warehouse automation system for picking and placing goods, or in a research and development environment for advanced robotic applications, the JAPMC – CP2230 – E provides the necessary control and coordination to ensure smooth and reliable operation of the robots.

For the logistics and warehousing industry, the Yaskawa JAPMC – CP2230 – E is applied in automated storage and retrieval systems (AS/RS), conveyor systems, and automated guided vehicles (AGVs). It coordinates the movement of AGVs, controls the speed and direction of conveyor belts, and manages the storage and retrieval of goods in warehouses, optimizing the logistics flow and improving the overall efficiency of material handling operations.

Related Products

- Yaskawa JAPMC – CP2330 – E: A more advanced model in the same product line, the JAPMC – CP2330 – E may offer enhanced processing power, larger memory capacity, and additional communication interfaces compared to the JAPMC – CP2230 – E. It is suitable for applications that require higher – performance control and more complex data processing, such as large – scale integrated manufacturing systems or advanced robotic applications with multiple axes of motion.

- Yaskawa MP3300iec Motion Controller: While having different characteristics, the MP3300iec Motion Controller can be used in conjunction with the JAPMC – CP2230 – E. The MP3300iec focuses on precise motion control of servo motors, while the JAPMC – CP2230 – E handles overall process control and system coordination. Together, they can form a comprehensive automation solution for applications that demand both accurate motion control and complex process management, such as high – precision machining centers or advanced robotic assembly lines.

- Yaskawa CP – 9200SH/CPU: Another programmable controller from Yaskawa, the CP – 9200SH/CPU has its own set of features and capabilities. It may be more suitable for certain types of industrial applications where the control requirements are different from those of the JAPMC – CP2230 – E. The CP – 9200SH/CPU can be considered as an alternative or complementary option depending on the specific needs of the automation project, such as simpler production lines or applications with lower – level control requirements.

- Yaskawa Sigma – 7 Series Servo Drives: As servo drives, the Sigma – 7 Series products work in tandem with the JAPMC – CP2230 – E. The JAPMC – CP2230 – E sends control signals to the Sigma – 7 Series servo drives to precisely regulate the speed, position, and torque of servo motors, enabling accurate motion control in automated production systems. They are an essential part of the overall automation solution, especially in applications where high – precision movement of mechanical components is required, such as in robotic arms and CNC machines.

Installation and Maintenance

Pre – installation preparation: Before installing the Yaskawa JAPMC – CP2230 – E, carefully read the detailed installation manual provided by Yaskawa. Ensure that the power supply at the installation site meets the specified requirements (usually a stable DC or AC power supply within the rated voltage range). Prepare all the necessary cables, including power cables, communication cables, and I/O cables, according to the wiring diagram in the manual. Select an appropriate installation location that is well – ventilated, away from sources of strong electromagnetic interference, and within the specified temperature and humidity range. Mount the controller securely using the provided mounting brackets or screws, and make sure all connections are properly tightened and insulated to prevent electrical hazards.

Maintenance recommendations: Regularly inspect the Yaskawa JAPMC – CP2230 – E for any signs of physical damage, such as cracks in the housing, loose connectors, or abnormal heat generation. Clean the exterior of the controller periodically using a dry, soft cloth to remove dust and debris, especially in dusty environments. Monitor the power supply voltage regularly to ensure it remains within the specified range. Check the communication interfaces for any errors, disruptions, or data loss in data transfer. Utilize the built – in diagnostic functions of the controller or the associated software tools to perform routine health checks. These checks can help detect potential issues like memory errors, communication failures, or abnormal I/O operations. If any abnormal behavior is detected, refer to the troubleshooting guide in the product manual or contact Yaskawa’s technical support team for assistance. Additionally, keep the firmware of the controller updated by installing the latest releases provided by Yaskawa, as these updates often include performance improvements, security enhancements, and bug fixes.

Product Guarantee

Yaskawa stands firmly behind the quality and reliability of the Yaskawa JAPMC – CP2230 – E. The product undergoes strict and comprehensive testing and quality control procedures during the manufacturing process to meet and exceed international industry standards. Yaskawa offers an extended warranty period, during which, in the event of a defect caused by faulty materials or workmanship, the company will provide free repair or replacement services. In addition to the warranty, Yaskawa’s professional technical support team is available to assist customers with any installation, operation, or maintenance issues. Whether it’s providing remote diagnostic support, helping with software configuration, or offering on – site service, Yaskawa is committed to ensuring that customers can rely on the JAPMC – CP2230 – E for their critical industrial control needs. This comprehensive product guarantee reflects Yaskawa’s confidence in the performance and durability of the Yaskawa JAPMC – CP2230 – E and its unwavering commitment to customer satisfaction.