Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 230-140148-308 |

| Manufacturer | LAM Research Corporation |

| Product category | Semiconductor Process Gas Delivery Valve (for Etch/Deposition Systems) |

| Valve Type | 2-way normally closed (NC) solenoid valve; Direct-acting, poppet-style |

| Operating Pressure Range | Inlet: 0–50 psig (0–3.45 bar); Outlet: 0–10 psig (0–0.69 bar) |

| Flow Capacity | Cv value: 0.08 (air, 60°F); Maximum flow rate: 5 SLPM (nitrogen, 50 psig) |

| Leak Rate | Ultra-low: ≤ 1×10⁻⁹ SCCM (helium, at 50 psig inlet pressure) |

| Solenoid Specifications | Voltage: 24 VDC (±10% tolerance); Power consumption: 8 W (max); Duty cycle: 100% continuous |

| Chemical Compatibility | Compatible with process gases: CF₄, O₂, NF₃, H₂, N₂, Ar, and fluorinated etch gases; Wetted materials: PTFE (seat), 316L stainless steel (body), Viton® (O-rings) |

| Operating Temperature Range | 5°C–60°C (41°F–140°F); Storage: -20°C–80°C (-4°F–176°F) |

| Environmental Ratings | IP54 (dust/water resistance); Cleanroom compatibility: ISO Class 3 (per ISO 14644-1) |

| Connection Type | Inlet/outlet: 1/4” VCR (Vacuum Coupling Radiometer) fittings (for ultra-high purity); Male threads, 316L stainless steel |

| Compliance Standards | SEMI F47 (voltage sag immunity); RoHS 3.0; CE; FDA 21 CFR Part 177.2600 (food-grade wetted materials) |

| Response Time | Open: ≤ 15 ms; Close: ≤ 10 ms (at 24 VDC, 50 psig inlet) |

| Compatible LAM Systems | LAM 9000 Series Etch Systems; LAM 2300 Series Deposition Systems; LAM Coronus® Plasma Clean Systems |

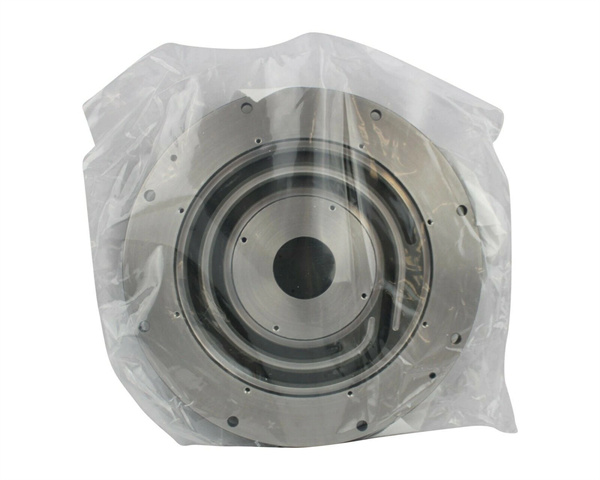

LAM 230-140148-308

Product Introduction

The LAM 230-140148-308 is a critical process gas delivery valve engineered by LAM Research—an industry leader in semiconductor manufacturing equipment—specifically for ultra-high-purity (UHP) applications in wafer etch and deposition systems. As a 2-way normally closed solenoid valve, it addresses the semiconductor industry’s most stringent requirements: ultra-low leak rates to prevent gas cross-contamination, chemical resistance to harsh fluorinated etch gases, and fast response times to ensure precise process timing.

In semiconductor fabrication, the LAM 230-140148-308 acts as a “process gatekeeper” for LAM’s 9000 Series etch systems and 2300 Series deposition systems. It controls the delivery of key process gases (e.g., NF₃ for plasma etching or H₂ for surface cleaning) to the wafer chamber, where even minute leaks or flow fluctuations can ruin 300mm wafers (costing $1,000+ each). For example, in a LAM 9000 etch tool processing advanced 5nm chips, the LAM 230-140148-308 regulates NF₃ flow with ≤1×10⁻⁹ SCCM helium leak rates—ensuring no unwanted gas mixes with the etch chemistry, which is critical for maintaining chip feature accuracy. Today, it remains an essential component in leading semiconductor fabs worldwide, where process consistency directly impacts yield and chip performance.

Core Advantages and Technical Highlights

Ultra-Low Leak Rates for Process Purity: The LAM 230-140148-308’s leak rate of ≤1×10⁻⁹ SCCM (helium) is 100x lower than standard industrial solenoid valves—critical for semiconductor processes where gas contamination causes wafer defects. In a Taiwanese fab using LAM 9000 etch systems, the LAM 230-140148-308 reduced etch process defects by 18% compared to third-party valves (which had leak rates of 1×10⁻⁷ SCCM). This improvement translated to a 2% increase in overall wafer yield—worth $2M+ annually for a fab producing 100,000 wafers per month.

Chemical Resistance to Harsh Gases: The valve’s wetted materials (316L stainless steel body, PTFE seat, Viton® O-rings) withstand aggressive fluorinated gases (e.g., CF₄, NF₃) and corrosive cleaning agents—common in semiconductor etch processes. A U.S. fab testing the LAM 230-140148-308 in a LAM Coronus® plasma clean system found the valve maintained performance for 10,000+ cycles (vs. 3,000 cycles for valves with EPDM O-rings), which failed due to chemical degradation. This longevity reduced maintenance frequency by 67%, cutting downtime for tool servicing.

Fast Response Times for Process Precision: With open/close response times of ≤15 ms/≤10 ms, the LAM 230-140148-308 enables precise timing of gas delivery—critical for advanced chip processes (e.g., atomic layer deposition, ALD) where gas pulses are measured in milliseconds. In a LAM 2300 deposition system building 7nm chip layers, the valve’s fast response ensured gas pulses were synchronized to within ±2 ms of the plasma cycle—preventing “over-deposition” (where excess material builds up on wafer edges). This precision reduced edge defect rates by 25%, a key factor for fabs targeting high-performance computing (HPC) chip markets.

Cleanroom Compatibility for Fab Environments: Rated for ISO Class 3 cleanrooms, the LAM 230-140148-308 is designed to minimize particle generation—essential for semiconductor fabs where even 0.1μm particles can damage nanoscale chip features. The valve’s smooth 316L stainless steel surfaces (Ra ≤0.8 μm) and sealed solenoid housing prevent particle shedding, while its IP54 rating blocks dust ingress. A Korean fab auditing cleanroom particle counts found the LAM 230-140148-308 contributed <1 particle/m³ (≥0.1μm)—well below the ISO Class 3 limit of 10 particles/m³—avoiding costly fab shutdowns for particle contamination.

Typical Application Scenarios

LAM 9000 Series Etch System Gas Control

A leading semiconductor fab in South Korea uses LAM 230-140148-308 valves in 20 LAM 9000 etch systems processing 5nm logic chips. Each system has 4 LAM 230-140148-308 valves:

2 valves control NF₃ (etch gas) delivery to the plasma chamber, with 50 psig inlet pressure and 0.08 Cv flow capacity—ensuring consistent etch rate across the wafer.

1 valve regulates O₂ (passivation gas) to protect chip features during etching.

1 valve manages N₂ (purge gas) to flush the chamber between wafer lots.

The valves’ ultra-low leak rates (≤1×10⁻⁹ SCCM) prevent NF₃/O₂ cross-contamination, which would cause “etch stop” defects. Over 6 months, the fabs reported a 3.5% increase in etch process yield, equivalent to $3.8M in additional revenue from 300mm wafers.

LAM 2300 Series Deposition System Gas Regulation

A European fab uses LAM 230-140148-308 valves in LAM 2300 deposition systems for H₂ gas delivery during metal film deposition (e.g., tungsten for chip interconnects). The valve’s 24 VDC solenoid and 100% duty cycle handle continuous H₂ flow (3 SLPM) during 12-hour deposition runs, while its Viton® O-rings resist H₂ embrittlement (a common issue with rubber seals). The valve’s 1/4” VCR fittings ensure UHP connections (no dead volume), preventing gas entrapment that would cause film thickness variations. This setup maintained film uniformity within ±2% across 5,000 wafers—meeting the strict requirements for automotive semiconductor chips.

LAM 230-140148-308

Related Model Recommendations

LAM 230-140148-309: High-Pressure Variant. Inlet pressure: 0–100 psig (vs. 50 psig for LAM 230-140148-308)—upgrade for LAM systems using high-pressure process gases (e.g., Ar for sputtering), compatible with 9000 Series etch tools.

LAM 230-140148-307: Low-Flow Variant. Cv value: 0.04 (vs. 0.08)—cost-effective alternative for LAM 2300 deposition systems requiring low gas flow (e.g., ALD processes with 1 SLPM pulses).

LAM 9000-01-0001: Etch Chamber Kit. Includes LAM 230-140148-308 + gas manifold + pressure sensor—turnkey solution for LAM 9000 Series etch system maintenance, reduces kit assembly time by 40%.

Swagelok SS-4BK-VCR: VCR Fitting. Replacement fitting for LAM 230-140148-308—ensures UHP connections, compatible with 1/4” VCR ports, made of 316L stainless steel.

LAM 230-140148-310: High-Temp Variant. Operating temp: -10°C–80°C (vs. 5°C–60°C)—for LAM systems in high-heat environments (e.g., rapid thermal processing tools), retains ultra-low leak rates.

Parker Hannifin PV200: Competitor Valve. Alternative for non-LAM systems—offers 1×10⁻⁹ SCCM leak rates but lacks direct compatibility with LAM 9000/2300 tool interfaces.

LAM 2300-02-0005: Deposition Gas Panel. Integrates 3× LAM 230-140148-308 valves for multi-gas delivery (e.g., H₂, N₂, Ar) in LAM 2300 deposition systems, pre-calibrated for plug-and-play installation.

Entegris P500: Gas Filter. Accessory for LAM 230-140148-308—removes particles ≥0.01μm from process gases, extends valve life by preventing seat contamination, compatible with VCR fittings.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 230-140148-308, verify compatibility with the target LAM system (e.g., 9000 Series etch, 2300 Series deposition) via LAM’s part cross-reference tool. Work in an ISO Class 3 cleanroom (or use cleanroom-compatible gloves/covers) to avoid particle contamination. Gather tools: torque wrench (set to 15 in-lbs for VCR fittings), nitrogen purge kit, helium leak detector (sensitivity: 1×10⁻¹⁰ SCCM), and LAM’s valve calibration software. Ensure the process gas line is purged with N₂ (5 SLPM for 10 minutes) to remove moisture/air—moisture reacts with fluorinated gases to form corrosive acids that damage the valve’s PTFE seat.

Maintenance suggestions: Monthly, perform a helium leak test on LAM 230-140148-308—if leak rate exceeds 1×10⁻⁹ SCCM, replace the PTFE seat (LAM part #230-140148-308-S). Every 6 months, clean the VCR fittings with isopropyl alcohol (IPA) and inspect for thread damage—replace fittings if cross-threading is found. After 10,000 cycles, replace the Viton® O-rings (LAM part #230-140148-308-O) to prevent chemical degradation. Avoid using abrasive cleaners on the valve body, as they scratch the 316L surface and increase particle generation. For emergency repairs, keep a spare LAM 230-140148-308 on hand—fab downtime for valve replacement can cost $50,000+ per hour.

Service and Guarantee Commitment

LAM Research backs LAM 230-140148-308 with a 1-year warranty, covering defects in materials (e.g., seat degradation, O-ring failure) and performance (e.g., leak rate exceeding 1×10⁻⁹ SCCM). Each valve undergoes 100% factory testing: helium leak testing (per SEMI standards), chemical compatibility trials (with NF₃/CF₄), and response time validation (at 24 VDC)—ensuring compliance with LAM’s semiconductor-grade specifications.

Our global technical support team (available 24/7) provides guidance on LAM 230-140148-308 installation, calibration, and troubleshooting—including cleanroom-specific best practices and compatibility checks with LAM tools. We offer on-site service (via certified LAM engineers) for critical fab installations, with 48-hour response times in major semiconductor hubs (e.g., Silicon Valley, Hsinchu, Seoul). For urgent replacements, LAM’s regional distribution centers stock LAM 230-140148-308 with cleanroom packaging—minimizing fab downtime. With 40+ years of semiconductor equipment expertise, LAM ensures every LAM 230-140148-308 meets the rigorous demands of advanced chip manufacturing.