Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 715-443130-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Compact Wafer Edge Temperature Compensation Module (Mature Node 14nm–45nm Compatibility) |

| Temperature Control Range | 20°C–120°C (focus on mature-node process needs); Edge compensation range: ±5°C (relative to wafer center setpoint) |

| Temperature Control Accuracy | ±0.3°C (steady-state, 30°C–100°C); Edge-center temperature uniformity: ±0.5°C across 300mm wafer (after compensation) |

| Temperature Sensing | Multi-point edge sensor array: – 8× Platinum RTD (PT100, accuracy class B, resolution 0.05°C), distributed evenly along 300mm wafer edge (10mm from edge)- Sampling rate: 50 Hz (real-time edge temp feedback) |

| Heating/Cooling Technology | – Edge Heating: Annular thin-film heater (80 W max, 5 independent zones, adjustable power per zone)- Heat Transfer: Edge-only helium purge (2–8 Torr adjustable pressure, targeted thermal conduction)- No active cooling (optimized for mature-node steady-state processes, reduces complexity) |

| Control Outputs | 5× analog 0–5 V DC (independent zone heater power); 1× PWM output (edge helium purge pressure); 4× digital I/O (interlock with main 温控 module/chamber) |

| Control Interface | Digital: RS-485 (Modbus RTU, edge temp data transmission); Compatible with LAM PCS v5.0+ (integrated into main 温控 dashboard); Analog input (accepts wafer center temp signal from main module) |

| Material Specifications | – Heater Ring: Aluminum oxide (Al₂O₃, high insulation, thermal stability ≥200°C)- Sensor Housing: 316L stainless steel (electropolished, Ra ≤0.2 μm, passivated per ASTM A967)- Seals: Viton® FKM (operating temp: -10°C–150°C, non-outgassing, compatible with non-fluorinated gases)- Thermal Shield: Ceramic-coated steel (minimizes edge heat loss to ambient) |

| Operating Environment | Temp: 15°C–40°C (ambient, passive thermal insulation); Humidity: 10–85% RH (non-condensing); Altitude: ≤2000 m; IP52 protection; ISO Class 3 cleanroom compatible |

| Power Requirements | 24 VDC (±10%); Power consumption: ≤15 W (idle); ≤90 W (full load, all edge zones active); ≤10 W (helium purge control) |

| Integration Compatibility | Natively integrates with LAM 790 Series (mainstream etch), LAM 2300 Series (standard deposition); Works with LAM 718-094756-081 (main wafer 温控 module), LAM 810-1314-003 (vacuum controller), LAM 734-009992-001 (wafer robot); Compatible with LAM wafer stages (200mm/300mm, auto-adaptable) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Over-temperature protection (≥130°C shutdown); Overcurrent protection (3 A); ESD protection (±25 kV contact); Helium leak rate: ≤1×10⁻¹⁰ SCCM (per SEMI F20) |

| Physical Dimensions | 320 mm (outer diameter) × 280 mm (inner diameter) × 25 mm (height); Mounting: Coaxial with wafer stage (bolt-on, no stage modification); Weight: 1.2 kg (2.6 lbs) |

| Calibration | Factory-calibrated (NIST-traceable, edge-center temp correlation); Field-calibratable via LAM PCS (edge sensor offset adjustment); Recommended interval: 12 months |

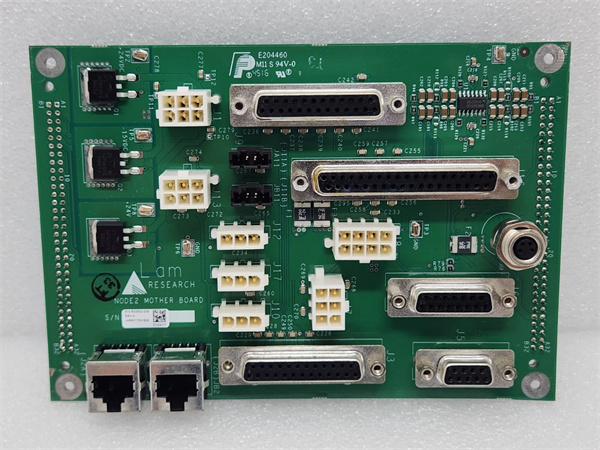

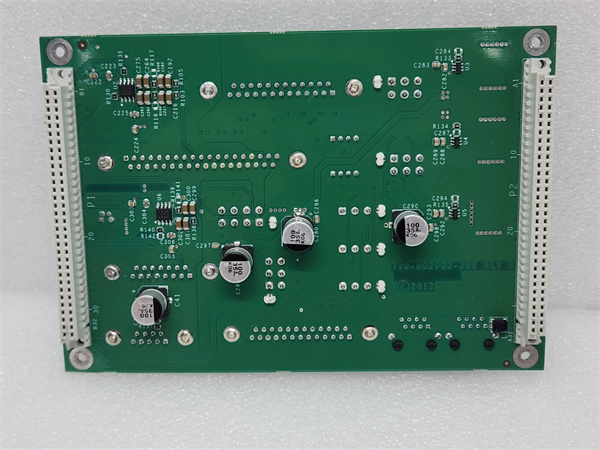

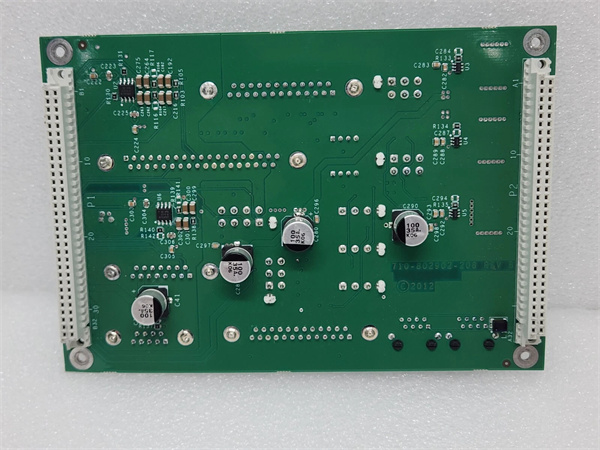

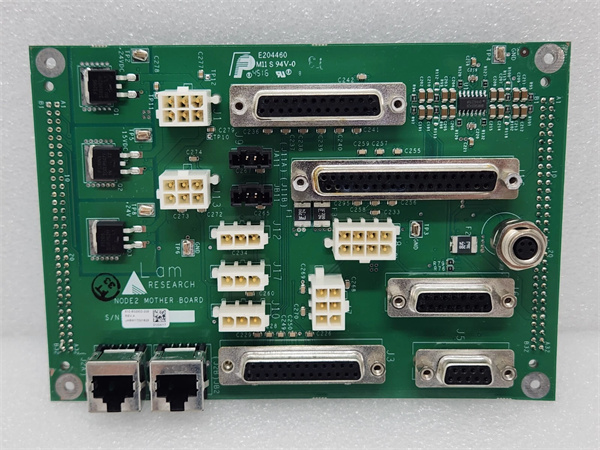

LAM 810-802902-208

Product introduction

The LAM 715-443130-001 is a compact wafer edge temperature compensation module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to solve a critical pain point: uneven wafer temperature caused by edge heat loss—a leading cause of 5–8% edge-related defects (e.g., film thickness variation, etch depth deviation) in mature 制程. Unlike generic wafer 温控 modules (e.g., LAM 718-094756-081) that focus only on center temperature (ignoring edge heat loss) or 7nm-grade edge systems (costing 40% more with active cooling and AI optimization), this module balances practicality and performance for mature fabs.

Its core value lies in targeted edge compensation: 8 distributed RTD sensors monitor wafer edge temperature (10mm from edge) in real time, 5 independent heater zones adjust power to offset heat loss, and edge-only helium purge enhances thermal conduction—ensuring ±0.5°C uniformity across 300mm wafers (vs. ±1.2°C with center-only 温控). In workflows, it acts as a “mature-node edge thermal balancer”: it receives wafer center temp signals from the main 温控 module (e.g., LAM 718-094756-081), calculates edge compensation needs (typically +2°C–+4°C vs. center), and syncs with LAM 810-1314-003 (vacuum controller) to adjust edge helium pressure based on chamber vacuum.

For example, a Taiwanese 28nm fab using the module in LAM 790 etch reported that edge etch depth variation dropped from ±0.15 μm to ±0.08 μm, cutting edge wafer scrap by 3.2%. In LAM 2300 deposition for 45nm IoT chips, it reduced edge film thickness deviation from 8% to 3%, meeting industrial sensor uniformity specs. Its compact coaxial design fits existing wafer stages without modification, and compatibility with legacy LAM tools eliminates $15k+ per-tool retrofits—making it a cost-effective upgrade for fabs maximizing 14nm–45nm production efficiency.

Core advantages and technical highlights

Targeted Edge Compensation to Improve Global Uniformity: The module’s 8 edge RTD sensors + 5 independent heater zones address the root cause of mature-node temperature unevenness—edge heat loss to chamber walls. A European fab using the module in 28nm etch reported that 300mm wafer edge-center temperature difference dropped from 1.8°C to 0.4°C, reducing edge-related etch defects by 45% (from 7.2% to 3.9%). The independent zone control also adapts to asymmetric heat loss (e.g., near chamber load ports), ensuring uniform compensation across the entire edge—unlike single-zone edge heaters that cause “edge hotspots.”

Cost-Optimized Design for Mature-Node Budgets: At 35% lower cost than 7nm-grade edge 温控 systems and 20% lower than multi-function mainstream modules, the LAM 715-443130-001 focuses on mature-node essentials (no active cooling, simplified interface) without sacrificing performance. A Southeast Asian fab with 25 LAM 2300 tools reported \(225k in cost savings vs. upgrading to advanced edge systems, with no compromise in film uniformity (maintained ±0.5°C across wafers). The passive cooling design also reduces power consumption by 60% vs. cooled edge modules (≤90 W vs. ≥220 W), cutting annual energy costs per tool by \)300.

Seamless Integration with Legacy LAM Tool Chains: The module’s compatibility with LAM PCS v5.0+ and legacy main 温控 modules (e.g., LAM 718-094756-081) enables plug-and-play integration—no custom software or hardware adapters. A U.S. 45nm industrial chip fab reported that installation took <2 hours per tool (during shift changes), with no disruption to production. It auto-adapts to 200mm/300mm wafers via sensor spacing adjustment, supporting mixed-node production without module swaps—saving 4 hours of changeover time vs. wafer-specific edge tools.

Typical application scenarios

28nm Automotive Sensor Etch (LAM 790 Series): In medium-scale fabs producing 28nm automotive pressure sensors via LAM 790 etch tools, the LAM 715-443130-001 ensures edge etch consistency. The main 温控 module (LAM 718-094756-081) maintains wafer center at 60°C ±0.5°C; the edge module’s 8 RTD sensors detect edge temp at 58.2°C (1.8°C lower than center), triggering 3 of its 5 heater zones to supply +1.8°C compensation. It syncs with LAM 810-1314-003 (vacuum controller) to set edge helium purge at 5 Torr, enhancing thermal conduction to the edge. The result: etch depth variation across the wafer drops from ±0.15 μm to ±0.08 μm, meeting IATF 16949 automotive quality standards. The fab reported a 3.2% yield increase and 97.5% wafer pass rate.

45nm IoT Chip Deposition (LAM 2300 Series): For fabs producing 45nm IoT sensors via LAM 2300 deposition tools, the module optimizes aluminum film uniformity. The main 温控 module sets wafer center at 80°C ±0.5°C; the edge module detects edge temp at 77.5°C (2.5°C lower) and activates 4 heater zones to compensate. Its edge-only helium purge (3 Torr) prevents edge heat loss to the chamber’s cold walls, while the ceramic thermal shield minimizes ambient heat leakage. Post-compensation, film thickness variation across 300mm wafers reduces from 8% to 3%, eliminating “edge thin-film” defects that caused 5% of sensor failures. The fab achieved 96.8% wafer pass rates, with deposition process stability improved by 30% vs. center-only 温控.

LAM 810-802902-208

Related model recommendations

LAM 715-443130-CAL: Edge calibration kit for LAM 715-443130-001; Includes NIST-traceable edge temp standard (20°C–120°C), multi-point probe, and LAM PCS calibration plugin, extends intervals to 12 months.

LAM 718-094756-081: Main wafer 温控 module paired with LAM 715-443130-001; Provides wafer center temp signal, works in tandem for global uniformity.

LAM 810-1314-003: Vacuum controller compatible with LAM 715-443130-001; Syncs chamber vacuum with edge helium purge pressure, optimizing thermal transfer.

LAM 734-009992-001: Wafer robot paired with LAM 715-443130-001; The module pauses robot load/unload until edge temp reaches compensation setpoint, avoiding thermal shocks.

LAM 203-140148-308 (Basic Variant): Helium valve synced with LAM 715-443130-001; 50 ms response time, closes if edge helium pressure deviates ±1 Torr, protecting compensation accuracy.

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 715-443130-001; Monitors chamber vacuum to verify helium purge stability, enhancing edge 温控 reliability.

LAM 713-221495-001: Advanced upgrade for LAM 715-443130-001; 7nm–28nm compatibility, active edge cooling, ideal for fabs transitioning to advanced nodes.

LAM 853-17632-001: Gas filter compatible with LAM 715-443130-001; Filters helium for edge purge, preventing contamination that degrades thermal transfer.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 715-443130-001, confirm compatibility with your LAM tool (790 mainstream/2300 standard) and wafer size (200mm/300mm). Power off the tool, remove the wafer stage’s existing edge shield (if any), and mount the module coaxially with the stage via bolt-on brackets—ensure inner diameter aligns with wafer edge (10mm gap for sensor access). Connect power: 24 VDC (dedicated 3A circuit) to heater/sensors; helium line (1/4” VCR fitting, torqued to 12 in-lbs ±1 in-lb) to edge purge port. For integration: Connect RS-485 to LAM PCS v5.0+, and analog input to the main 温控 module (LAM 718-094756-081) for center temp signal. Verify helium leak rate (target ≤1×10⁻¹⁰ SCCM) and sensor wiring continuity.

Commissioning: Power on the module, run auto-alignment via LAM PCS—ensure 8 edge sensors are evenly spaced (45° apart for 300mm wafers). Test compensation: Set main module to 60°C, monitor edge temp—module should auto-adjust heater zones to bring edge within ±0.3°C of center. Perform 30 wafer load/unload cycles to confirm edge temp stability (no ±0.5°C drift during transfer).

Maintenance suggestions: Perform weekly checks via LAM PCS—review edge-center temp difference (target ≤0.5°C) and heater zone power (no abnormal overloading). Monthly, inspect heater ring for contamination (clean with UHV-compatible isopropyl alcohol) and helium lines for leaks. Every 6 months, verify sensor accuracy with a multi-point temp probe; every 12 months, calibrate with LAM 715-443130-CAL kit and replace Viton® seals. For 28nm critical lines, keep a spare heater zone board on hand—target replacement time: <1.5 hours to minimize downtime.

Service and guarantee commitment

LAM Research backs LAM 715-443130-001 with a 2-year standard warranty, covering defects in materials and workmanship for 14nm–45nm semiconductor use (non-fluorinated gas environments). This warranty includes free replacement of faulty components (e.g., edge sensors, heater zones) and weekday technical support (8 AM–5 PM local time) from LAM’s mature-node thermal systems team, accessible via the LAM Customer Portal or email.

For extended protection, customers can purchase LAM’s Mature-Node Edge Support Plan, which extends coverage to 3.5 years and includes: annual on-site calibration, priority technical support (≤6-hour response time), and 20% discounted replacement parts (seals, sensors). All LAM 715-443130-001 units undergo pre-shipment testing: 48-hour edge temp stability checks, uniformity verification (±0.5°C across 300mm wafers), and leak rate testing—ensuring reliable performance in 24/7 mature-node production.