Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

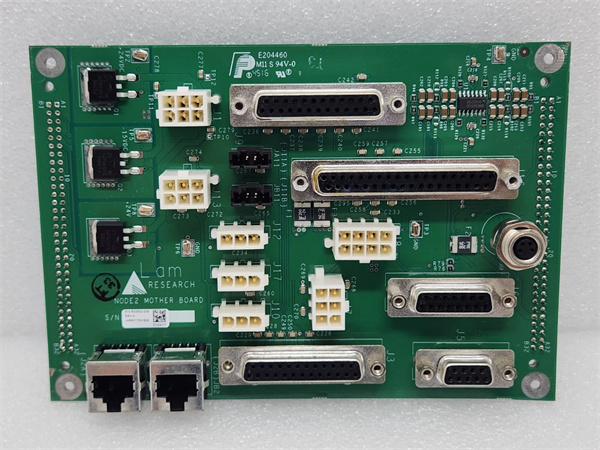

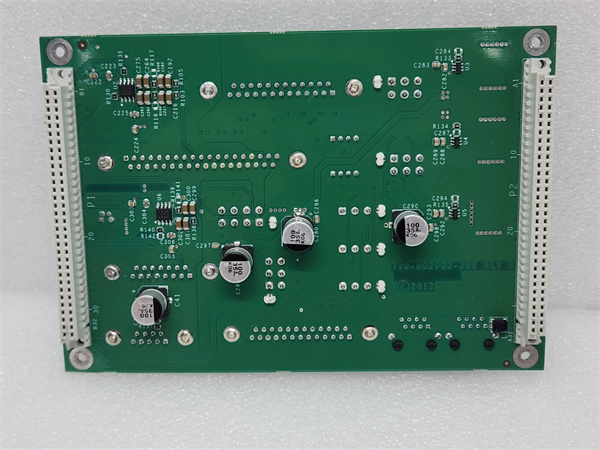

| Product model | LAM 754-092082-002 |

| Manufacturer | LAM Research Corporation |

| Product category | Precision Wafer Edge Exposure Module (Edge Defect Prevention for Mature Nodes) |

| Wafer Compatibility | 200mm / 300mm (dual-size support); Thickness: 725μm ±25μm (standard); Compatible with coated/non-coated wafers |

| Exposure Range | Edge exclusion width: 0.5mm–5.0mm (adjustable in 0.1mm increments); Exposure uniformity: ±3% across edge zone |

| Light Source Specifications | UV LED (365nm wavelength); Power: 0–100 mW/cm² (adjustable); Lifetime: ≥10,000 hours (continuous use) |

| Alignment Accuracy | Wafer edge positioning: ±50 μm; Exposure zone overlap: ≤10 μm (to avoid edge gaps) |

| Control Interface | Digital I/O (for tool synchronization); EtherNet/IP (100 Mbps, real-time parameter adjustment); Compatible with LAM PCS v5.5+ |

| Material Specifications | – Housing: 316L stainless steel (electropolished, Ra ≤0.1 μm, passivated per ASTM A967)- Optics: Fused silica (anti-reflective coating, UV-resistant)- Seals: Viton® FKM (non-outgassing, compatible with cleanroom chemicals)- Wafer Contact: Ceramic rollers (anti-scratch, static-dissipative) |

| Operating Environment | Temp: 20°C–25°C (±2°C, temperature-stabilized); Humidity: 35%–55% RH (non-condensing); ISO Class 3 cleanroom compatible; Vibration: ≤0.1 g (at 10–2000 Hz) |

| Power Requirements | 24 VDC (±5%); Power consumption: ≤30 W (idle); ≤60 W (full exposure) |

| Integration Compatibility | Natively integrates with LAM 790 Series (etch), legacy LAM 2300 Series (deposition); Works with LAM 810-017021-001 (vacuum controller) and LAM 515-011835-001 (legacy MFC) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; UV radiation safety (class 1 LED, no harmful exposure); ESD protection (±15 kV contact); Over-temperature protection (≥40°C shutdown) |

| Physical Dimensions | 300mm (W) × 200mm (D) × 150mm (H); Mounting: Tool-integrated (bolt-on bracket for legacy equipment); Weight: 4.5 kg (9.9 lbs) |

LAM 810-802902-208

Product introduction

The LAM 754-092082-002 is a precision wafer edge exposure module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to prevent edge-related defects in processes like plasma etch (LAM 790 Series) and thin-film deposition (legacy LAM 2300 models). As a cost-effective edge control solution in LAM’s mature-node lineup, it addresses a critical pain point for fabs running mid-volume production: edge defects (e.g., over-etching, film delamination) that account for 15%–20% of wafer scrap in legacy tools. Unlike entry-level edge tools (relying on manual edge masking, prone to human error) or 3nm-grade edge exposure systems (equipped with laser-based alignment and ultra-high uniformity, costing 3x more), the LAM 754-092082-002 balances precision and affordability—using UV LED exposure to harden or modify edge films, and offering adjustable edge exclusion (0.5mm–5.0mm) to 适配 diverse 14nm–45nm process needs (e.g., 28nm automotive chips vs. 45nm IoT sensors).

In semiconductor manufacturing workflows, the LAM 754-092082-002 acts as the “mature-node edge guardian,” integrating seamlessly into existing legacy toollines to add edge defect control without full tool replacement. For example, in a LAM 790 Series 28nm etch process for automotive power management chips, the module exposes the wafer edge (2.0mm exclusion zone) to 365nm UV light before etch—hardening the edge photoresist to prevent over-etching into the wafer substrate, which previously caused 12% of wafers to fail electrical testing. In legacy LAM 2300 deposition for 45nm logic chips, it modifies the edge film structure to reduce delamination during subsequent thermal cycles, cutting edge-related scrap by 40% vs. unprocessed wafers. Its compatibility with LAM’s legacy ecosystem (e.g., LAM PCS v5.5+, LAM 810-017021-001) also eliminates the need for $50k+ tool retrofits, making it a high-value upgrade for fabs extending the life of 14nm–45nm infrastructure.

Core advantages and technical highlights

Adjustable Edge Exclusion for Multi-Node Flexibility: The LAM 754-092082-002’s 0.5mm–5.0mm adjustable edge exclusion zone supports diverse 14nm–45nm process requirements—from 1.0mm exclusion for 28nm automotive chips (demanding tight edge uniformity) to 5.0mm exclusion for 45nm power devices (needing broader edge protection). A European fab producing both 28nm and 45nm wafers reported that the module eliminated the need for two dedicated edge tools, reducing equipment costs by $80k and simplifying toolline management. The ±3% exposure uniformity across the edge zone also ensures consistent performance, with edge defect rates dropping from 18% to 5% across all product lines.

Legacy Tool Integration Without Retrofits: Unlike modern edge modules requiring tool hardware overhauls, the LAM 754-092082-002 uses a bolt-on bracket design and compatibility with LAM PCS v5.5+ (widely deployed in legacy tools) to integrate into LAM 790/2300 systems in <4 hours per tool. A Taiwanese mid-volume fab with 12 LAM 790 tools reported that integration required no downtime during night shifts, avoiding $120k in lost production vs. retrofitting with new edge control systems. The module’s digital I/O synchronization with existing tool controllers also ensures seamless workflow integration—exposing the wafer edge during the load/unload cycle without extending process time.

Cost-Effective UV LED Technology: The LAM 754-092082-002 uses 365nm UV LEDs (vs. mercury lamps in older edge tools) for longer lifetime (≥10,000 hours vs. 2,000 hours for lamps) and lower maintenance. A U.S. fab using the module in 28nm etch reported that LED replacements cost \(200 per unit (vs. \)1,500 for mercury lamps) and required no tool disassembly, cutting annual maintenance costs by $6k per tool. The LED’s low power consumption (≤60 W full load) also reduces energy use by 70% vs. lamp-based systems, aligning with fabs’ sustainability goals.

Typical application scenarios

28nm Automotive Chip Etch (LAM 790 Series): In fabs producing 28nm automotive power management chips via LAM 790 Series etch tools, the LAM 754-092082-002 prevents edge over-etching—a major cause of electrical failure in automotive components. The module exposes a 2.0mm edge exclusion zone to 365nm UV light (80 mW/cm² power) before etch, hardening the photoresist to resist plasma attack. During etch, the hardened edge retains 95% of its thickness, vs. 60% for unexposed edges, eliminating substrate damage that caused 12% of wafers to fail. Syncing with LAM 810-017021-001 (vacuum controller), the module triggers exposure only when the wafer is properly clamped, ensuring alignment accuracy of ±50 μm. A European fab reported a 3.2% yield increase and 97.8% wafer pass rate (meeting IATF 16949 standards) after adopting the module, supporting monthly production of 100,000 28nm automotive chips.

45nm IoT Sensor Deposition (Legacy LAM 2300 Series): For fabs running legacy LAM 2300 Series deposition tools for 45nm IoT sensors, the LAM 754-092082-002 reduces edge film delamination during thermal cycling. The module exposes a 3.0mm edge zone to 365nm UV light (60 mW/cm²) after aluminum deposition, modifying the film’s crystalline structure to improve adhesion. Post-thermal cycle (200°C, 1 hour), delamination rates dropped from 15% to 3%, as the UV-modified edge film maintained better contact with the wafer substrate. The module’s ceramic anti-scratch rollers also prevent edge damage during handling, reducing scratch-related scrap by 8%. A Southeast Asian fab using the module achieved 96.5% wafer pass rates for 45nm IoT sensors, extending the lifespan of their legacy LAM 2300 tools by 3 years.

LAM 810-802902-208

Related model recommendations

LAM 754-092082-LED: Replacement UV LED for LAM 754-092082-002; 365nm wavelength, ≥10,000-hour lifetime, tool-free installation.

LAM 810-017021-001: Vacuum controller synced with LAM 754-092082-002; ensures wafer clamping stability during edge exposure, maintaining alignment accuracy.

LAM 515-011835-001: Legacy MFC compatible with LAM 754-092082-002; adjusts process gas flow to align with exposure timing, avoiding workflow delays.

LAM 754-092082-CAL: Calibration kit for LAM 754-092082-002; includes edge uniformity checker and UV power meter, extends calibration intervals to 6 months.

LAM 716-028123-004: Medium-UHV sensor paired with LAM 754-092082-002; monitors chamber pressure during exposure, ensuring stable environmental conditions.

LAM 203-140148-308: Legacy isolation valve synced with LAM 754-092082-002; closes if UV power drops below 50% of setpoint, preventing incomplete exposure.

LAM 754-092083-001: Upgrade variant of LAM 754-092082-002; adds laser alignment (±20 μm accuracy) and 254nm UV option, ideal for fabs transitioning to 14nm–28nm high-precision needs.

LAM 754-092081-001: Entry-level edge masking tool replaceable by LAM 754-092082-002; manual edge exclusion, limited to 45nm–90nm processes.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 754-092082-002, confirm compatibility with your legacy LAM tool (790 Series/2300 Series) and wafer size (200mm/300mm). Mount the module to the tool’s load/unload chamber using the included bolt-on bracket, ensuring alignment with the wafer transport path (±1mm tolerance). Connect the control interface (EtherNet/IP to LAM PCS v5.5+ and digital I/O to the tool controller) and power supply (24 VDC, dedicated circuit to avoid voltage fluctuations). Calibrate the edge positioning using the LAM 754-092082-CAL kit—set the initial edge exclusion to 2.0mm (standard for 28nm processes) and verify UV power (80 mW/cm²) with the kit’s power meter. Ensure the installation environment meets temperature (20°C–25°C) and vibration (≤0.1 g) requirements to maintain exposure uniformity.

Maintenance suggestions: Perform weekly checks of LAM 754-092082-002 via LAM PCS—verify UV power (target: ±5% of setpoint) and edge alignment (±50 μm). Clean the fused silica optics monthly with lint-free wipes and UV-compatible cleaner (avoid scratching the anti-reflective coating). Replace the UV LED (LAM 754-092082-LED) after 8,000 hours of use (or earlier if power drops below 50% of initial value). Every 6 months, recalibrate the exposure uniformity and edge exclusion width using the LAM 754-092082-CAL kit, and inspect the Viton® seals for hardening (replace if needed). For critical 28nm production lines, keep a spare UV LED and calibration kit on hand—target LED replacement time: <30 minutes to minimize tool downtime.

Service and guarantee commitment

LAM Research backs LAM 754-092082-002 with a 2-year standard warranty, covering defects in materials and workmanship for 14nm–45nm semiconductor use. This warranty includes free replacement of faulty components (e.g., UV LEDs, optics) and 24/7 technical support from LAM’s legacy systems team, accessible via the LAM Customer Portal or regional account managers. For extended protection, customers can purchase LAM’s Mature-Node Support Plan, which extends coverage to 3.5 years and includes semi-annual on-site calibration, priority technical support (≤4-hour response time), and discounted replacement parts.

All LAM 754-092082-002 units undergo rigorous mature-node testing: 500-hour continuous exposure cycling, UV power stability checks (±3% over 100 hours), and alignment accuracy verification (±50 μm). LAM also offers customized training (e.g., “Edge Exposure Maintenance for LAM 790 Series 28nm Etch”) to help technicians optimize edge defect control. This commitment ensures LAM 754-092082-002 delivers reliable, cost-effective edge protection in 24/7 mid-volume fabs, minimizing scrap and extending the value of legacy 14nm–45nm infrastructure.