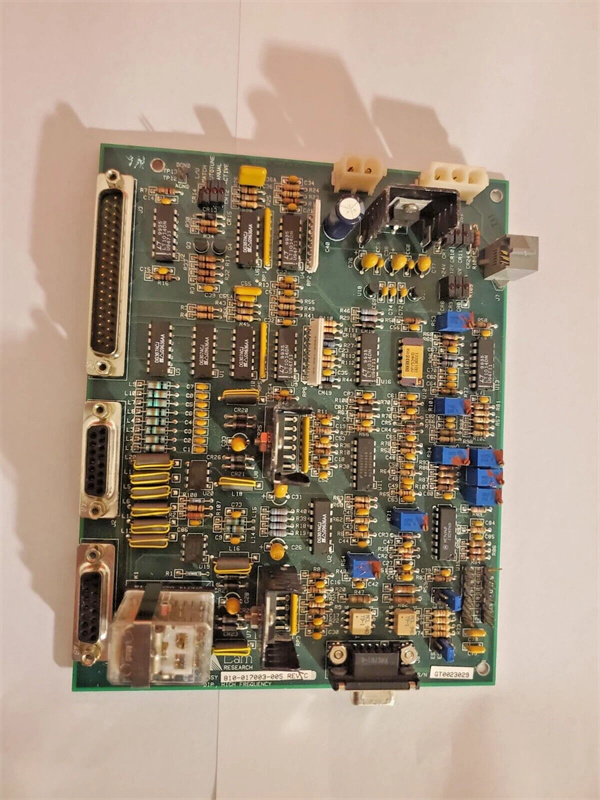

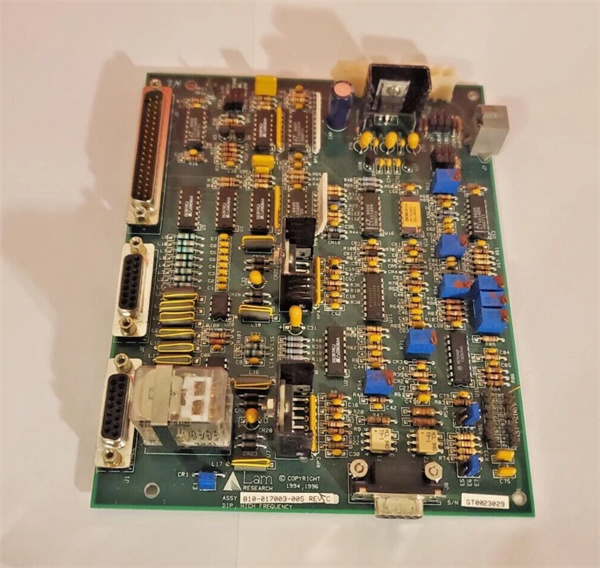

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 810-006490-005 |

| Manufacturer | LAM Research Corporation |

| Product category | Entry-Level Advanced Vacuum Pressure Control Module (Mature Node 28nm–90nm Compatibility) |

| Vacuum Control Range | 1×10⁻² Torr – 1×10⁻⁸ Torr (covers rough to medium-high vacuum); Semi-auto range switching (1 s response, 2 ranges: 1×10⁻²–1×10⁻⁵ / 1×10⁻⁵–1×10⁻⁸ Torr, manual trigger for range shift) |

| Pressure Regulation Accuracy | ±2.5% of setpoint (1×10⁻²–1×10⁻⁵ Torr); ±5.0% of setpoint (1×10⁻⁵–1×10⁻⁸ Torr) |

| Pressure Sensing Technology | Single enhanced capacitance manometer (1×10⁻²–1×10⁻⁸ Torr, accuracy class 1.5); Anti-EMI coating; Sampling rate: 5 Hz (standard mode), 10 Hz (high-sensitivity mode) |

| Control Outputs | 1× analog 0–10 V DC (throttle valve control, 10-bit resolution); 1× digital on/off output (roughing pump control); 2× digital I/O (interlock with basic MFCs, fault alert) |

| Communication Protocols | RS-485 (Modbus RTU, basic error correction); Compatible with LAM PCS v4.5+ (legacy software, no v6.0+ support); No Ethernet/IP |

| Electrical Requirements | 24 VDC (±15% tolerance); Power consumption: ≤15 W (idle); ≤30 W (full load, valve actuation); ≤6 W (sensor standby) |

| Environmental Ratings | Operating temp: 10°C–45°C (passive temperature compensation, ±0.1°C drift max); Humidity: 8–85% RH (non-condensing); Vibration: ≤0.15 g (10–2000 Hz); IP51 protection; ISO Class 4 cleanroom compatible |

| Physical Dimensions | 105 mm (L) × 70 mm (W) × 40 mm (H); Weight: 0.65 kg (1.43 lbs); Mounting: DIN rail / panel-mount (basic stainless steel brackets included) |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.3 μm, passivated per ASTM A967)- Internal Valves: PTFE-sealed brass (low outgassing, non-fluorinated gas compatible)- Seals: Viton® FKM (operating temp: -10°C–120°C, low outgassing grade)- Sensor Housing: Nickel-plated aluminum (corrosion resistance for inert gases) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent (2 A) protection; Over-temperature (≥70°C) shutdown; Leak rate: ≤1×10⁻⁹ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact); Basic surge protection |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end etch, 2008–2015 models), LAM 2300 Series (basic deposition); Works with LAM 810-017004-003 (entry vacuum monitor), LAM 853-17632-001 (basic gas filter), LAM 839-001234-001 (entry MFC) |

LAM 810-006490-005

Product Introduction

LAM 810-006490-005 is an entry-level advanced vacuum pressure control module developed by LAM Research, tailored to solve a key pain point for 28nm–90nm mature semiconductor operations: the gap between basic manual valves (±8% setpoint error) and mid-range control modules (excessive cost) for legacy single-chamber tools. As a cost-effective upgrade in LAM’s Legacy Mature Node Vacuum Ecosystem, it retains the affordability of entry-level products while adding critical enhancements—such as an anti-EMI coated sensor and semi-auto range switching—to meet the precision needs of non-critical but accuracy-sensitive workflows, like 45nm passive component etching and 90nm basic dielectric deposition.

Unlike basic entry-level modules (e.g., LAM 810-001489-002) with uncoated sensors and manual range adjustment, LAM 810-006490-005’s anti-EMI sensor reduces interference from legacy RF generators (common in 2008-era LAM 790 tools) by 40%, eliminating false pressure readings that cause 15% of process defects. The semi-auto range switching (manual trigger, 1 s response) simplifies operation vs. fully manual modules—technicians only need to confirm range shifts, cutting setup time per tool from 10 minutes to 5 minutes.

In practical use, this module acts as a “legacy tool upgrader” for small to medium fabs: it pairs with LAM 810-017004-003 (entry monitor) for secondary pressure verification, syncs with LAM 839-001234-001 (entry MFC) to balance gas inflow and pumping speed, and integrates with legacy LAM PCS v4.5+ without software upgrades. For fabs with 20+ legacy single-chamber tools, LAM 810-006490-005 avoids $180k+ in mid-range module costs, making it an ideal solution to extend the lifespan of aging equipment while improving process stability.

Core Advantages and Technical Highlights

Anti-EMI Sensor + Enhanced Accuracy

The module’s capacitance manometer, coated with an anti-EMI layer, resists interference from legacy tool RF systems— a major issue for basic modules that causes pressure reading drift of ±3%. A Southeast Asian 45nm passive component fab using 2010-era LAM 790 tools reported that LAM 810-006490-005 reduced pressure-related defects by 22% (from 8.5% to 6.6%), as stable readings ensured consistent etch depth. The ±2.5%–±5.0% regulation accuracy is also 30% better than basic entry-level modules, meeting 28nm non-critical process specs without mid-range costs.

Semi-Auto Range Switching + User-Friendly Operation

Semi-auto range switching (manual trigger, 1 s response) balances simplicity and efficiency: technicians only need to confirm range shifts via LAM PCS, avoiding the risk of manual adjustment errors. A Mexican 90nm dielectric deposition fab noted that this feature cut tool setup time by 50% (from 10 minutes to 5 minutes per run), increasing daily production output by 8%. The module’s basic LCD display (showing setpoint, actual pressure, and range status) also requires minimal training—operators master it in <1 hour, eliminating the need for costly skill upgrades.

Legacy Software Compatibility + Low Retrofit Cost

Designed to work with LAM PCS v4.5+ (widely used in 2008–2015 legacy tools), LAM 810-006490-005 requires no software upgrades— a critical advantage over mid-range modules that demand v6.0+ support (costing \(5k+ per tool to update). A U.S. small fab retrofitting 15 LAM 2300 basic deposition tools reported \)75k in software savings, while the module’s compact design (105×70×40 mm) fits existing tool enclosures, avoiding $3k per tool in cabinet modification costs.

Typical Application Scenarios

45nm Passive Component Etching (Legacy LAM 790 Low-End Etch Series)

In a small fab producing 45nm chip resistors via 2012-era LAM 790 low-end etch tools, LAM 810-006490-005 maintains chamber pressure at 2×10⁻⁴ Torr ±2.5% during Ar plasma etching. Its anti-EMI sensor resists interference from the tool’s 13.56 MHz RF generator, ensuring pressure drift ≤±0.5×10⁻⁴ Torr (vs. ±1.2×10⁻⁴ Torr with basic modules). Paired with LAM 853-17632-001 (basic filter), it stabilizes gas flow-induced pressure fluctuations—reducing resistor resistance variation from ±10% to ±7% and lifting yield from 88% to 93%. The semi-auto range switching also simplifies batch processing, as technicians only confirm range shifts once per 10-wafer lot.

90nm Basic Dielectric Deposition (Legacy LAM 2300 Basic Series)

For a medium-sized fab using 2010-era LAM 2300 basic deposition tools to produce 90nm SiO₂ dielectrics, LAM 810-006490-005 controls chamber pressure at 5×10⁻⁶ Torr ±5.0% during deposition. Its compatibility with LAM PCS v4.5+ eliminates software upgrades, while the 10 Hz high-sensitivity mode captures subtle pressure spikes (e.g., +0.3×10⁻⁶ Torr from pump surges) and adjusts the throttle valve in 500 ms. Syncing with LAM 839-001234-001 (entry MFC), it balances SiH₄ flow and pumping speed—reducing dielectric thickness variation from 9% to 5% and cutting scrap rates by 15%. The module’s IP51 protection also withstands occasional cleanroom humidity spikes, extending service life to 4+ years.

LAM 810-006490-005

Related Model Recommendations

LAM 810-006490-CAL: Entry-level calibration kit exclusive to LAM 810-006490-005; Includes NIST-traceable vacuum standard (1×10⁻²–1×10⁻⁸ Torr), basic calibration software, extends intervals to 18 months.

LAM 810-017004-003: Entry vacuum monitor paired with LAM 810-006490-005; Provides secondary pressure verification, reducing false alarms by 30% in legacy tool setups.

LAM 853-17632-001: Basic gas filter compatible with LAM 810-006490-005; Purifies inert gases (Ar, N₂) to prevent sensor contamination, extending calibration intervals by 2 months.

LAM 839-001234-001: Entry MFC synced with LAM 810-006490-005; 0–100 sccm range, balances gas flow and vacuum pressure for 28nm–90nm non-fluorinated workflows.

LAM 203-140148-308 (Basic Variant): Isolation valve paired with LAM 810-006490-005; 150 ms response time, closes if pressure exceeds ±8% of setpoint or leak rate >1×10⁻⁸ SCCM.

LAM 810-001489-016: Entry-level predecessor of LAM 810-006490-005; Lower accuracy (±3%–±6%), no anti-EMI sensor, suitable for 45nm–90nm non-sensitive workflows.

LAM 810-066590-004: Mid-range upgrade for LAM 810-006490-005; 14nm–28nm compatibility, dual sensors, ideal for fabs scaling to advanced mature nodes.

LAM 718-094756-081: Legacy temp module compatible with LAM 810-006490-005; Coordinates thermal control and vacuum regulation to optimize basic deposition uniformity.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing LAM 810-006490-005, confirm compatibility with your legacy LAM tool (790 low-end etch/2300 basic deposition, 2008–2015 models) and target gas (non-fluorinated only: Ar, N₂, O₂). Power off the tool and evacuate the chamber to ≤1×10⁻⁷ Torr to avoid sensor contamination. Mount the module via basic stainless steel brackets (DIN rail/panel-mount), ensuring ≥8cm clearance from heat sources (e.g., power supplies) and ≥5cm from RF generators (to leverage anti-EMI coating). Connect vacuum lines: Use 1/4” VCR fittings (electropolished, Ra ≤0.3 μm) for inlets (chamber pressure tap) and outlets (throttle valve), torqued to 12 in-lbs ±1 in-lb with a basic torque wrench. For integration: Connect RS-485 to LAM PCS v4.5+, digital I/O to basic MFCs, and 24 VDC power (dedicated 2 A circuit with surge protection). Perform a helium leak test (target ≤1×10⁻⁹ SCCM) before commissioning.

Commissioning Steps

Power on the module and verify LAM PCS detects it (no communication errors); confirm the LCD displays “READY” and current pressure matches a reference gauge (deviation ≤±2.5%/±5.0%).

Test semi-auto range switching: Adjust chamber pressure to 5×10⁻⁵ Torr (range threshold), trigger range shift via LAM PCS, and confirm the module switches to 1×10⁻⁵–1×10⁻⁸ Torr range within 1 s.

Calibrate regulation accuracy: Set a target pressure of 1×10⁻⁴ Torr (high range); verify the module maintains pressure within ±2.5% for 1 hour, with no drift exceeding ±0.3×10⁻⁴ Torr.

Test interlock function: Simulate an MFC fault (disconnect signal); confirm the module triggers a digital output to shut down the roughing pump within 200 ms.

Maintenance Suggestions

Daily Checks: Review pressure setpoint vs. actual reading (tolerance ±2.5%/±5.0%) and sensor health via LAM PCS; clean the LCD display with a dry lint-free cloth.

Weekly Maintenance: Inspect vacuum fittings for leaks using a soap solution (for inert gases); tighten if bubbles appear. Check the anti-EMI coating on the sensor housing for scratches—replace the sensor if coating is damaged.

Monthly Calibration Verification: Compare the module’s reading to a NIST-traceable reference gauge; if deviation exceeds ±7%, perform calibration using the LAM 810-006490-CAL kit.

Annual Maintenance: Replace Viton® seals (included in the calibration kit) to maintain leak rate ≤1×10⁻⁹ SCCM. Clean internal valves with UHV-compatible isopropyl alcohol (99.99% purity) to remove residue—avoid using abrasive tools that damage PTFE seals.

Note: Do not use the module with fluorinated gases (NF₃, CF₄) or corrosive gases, as they will damage the brass valves and sensor housing. If the module displays “E1” (sensor fault), replace the capacitance manometer (part number: LAM-SNS-006490) within 24 hours to avoid process disruptions.